If you follow Aerospace Highway north out of Mojave, California, take a small road off to the east, continue as it becomes gravel, and then sand, and pass a dry lake bed, you’ll end up at the Friends of Amateur Rocketry (FAR) launch site. These 10 acres of bare desert nestled between mountains and bordering a California desert tortoise preserve are scarred with blast marks from hundreds of experimental rocket launches.

It’s here, on a hot, sunny Sunday in April, that Carbon Origins, a startup consisting of four recent Case Western Reserve University engineering students, has set up Phoenix 0.3, a 10-foot-long, 4-inch-diameter silver and black needle of a rocket. Inside are six commercial flight controllers, plus three of their unique, custom-built boards designed to track the rocket’s flight past Mach 2.5 and up to 43,000 feet.

Disassembled, the rocket fits in the back of Danna Torio’s Toyota Highlander, which is how Carbon Origins got the rocket out to the FAR site from their house/corporate headquarters in nearby California City. Amogha Srirangarajan stands beside the rocket on the platform, arming the electronics manually. They beep through the fiberglass body in acknowledgment.

“She’ll be dented and scratched when she comes back,” he says, affectionately.

A few feet away, Kailey Shara makes sure the GPS unit is locked onto satellites. Then everybody retreats to a nearby bunker, and Srirangarajan video-calls Peter Dixon, their fourth co-founder, who could not be present.

Nobody slept last night, Srirangarajan says, but Torio and Jaimie Hadden, who volunteered at the launch, admit to catching naps in the car.

The countdown begins, from 10. It reaches zero, and nothing happens.

Carbon Origins can trace its trajectory to the rocketry club at Case Western in Cleveland. Srirangarajan founded the group, which expanded into one of the most popular clubs at the university.

The club went to Utah to launch an 18-foot, two-stage rocket. It blew up. More than $23,000 worth of school, sponsor, and personal money went up in smoke, and they didn’t know why because the flight controller sensor array the rocket needed to tell them what happened didn’t yet exist.

Eventually, they pieced it together, based on footage of the launch and an exhaustive process of picking up the scattered debris. The first stage lifted off fine. At best guess — an educated guess, but still not completely certain — the flight controller, which ignites the second stage, did so before stage 1 was finished. It wrecked the body, says Shara. The engine blew right threw it.

“It was a pretty ambitious 2-stage rocket,” she says. “It was kind of pushing the capabilities of that flight controller.”

Some in the club thought they could do better. Srirangarajan, Shara, Dixon, and Torio split off to start Carbon Origins, with the dual goals of making it easier for citizens to explore space and building the tools, including that missing flight controller, that would help them do that. The flight controller became a custom, durable, Arduino-compatible device called Apollo.

“That was the point at which we said, this is more than a hobby,” says Srirangarajan, who is president and CEO of Carbon Origins. “From the ashes was born another rocket, and a company.”

“That is our single goal, space, and we’ll do everything we can to make sure that people like us, when they get to universities, and when they get to a part in their life where they have the basic skills to do something cool, they have this resource to put stuff in space,” he says.

In the summer of 2014, they moved to California City, rented a four-bedroom house with a rocky yard and heavily taxed air conditioner, and set up shop. Literally — they built a shop in the living room, with a drill press, shop vac, MakerBot, a big monitor for CAD, bright work lights on stands, and a big bank of drawers containing bolts and other small parts. There are five whiteboards covered in calculations and diagrams, plus a fridge with three faces covered in dry-erase markings.

Five more whiteboards decorate the walls of the garage, which has been converted to a white-walled office with fluorescent lights. There, the crew has a Form1 printer, vinyl cutter, DJI Phantom, cases of Red Bull, and inward-facing desks, like the bridge of a star cruiser. There’s no garage door opener; the door itself has been insulated to resist the desert heat and sealed around the edges, though sand and bugs tend to slip in.

But maybe the most important feature of the house stands next to the kitchen. It is a 1:8 scale model of a payload-carrying, space-bound, two-stage rocket that is their ultimate goal. They don’t know what’ll go in it, but its purpose is to make it easier for Makers to launch stuff into space. “We built this so we could have a physical reminder of what we’re aiming for,” says Torio.

Nearly everything you’d need to build a rocket resides in the house with them. “Having an apartment like this, where you can wake up and walk straight to your shop, that’s incredible,” says Srirangarajan. They hardly even need to leave; Torio’s car is the only one they have, and Srirangarajan says he seldom carries his wallet — it’s rare that an expenditure isn’t related to the business.

The lack of distraction is a big part of why they moved to California City, population 14,120. They don’t exactly have a lot to do there, socially speaking. They go flying in a Cessna 172 (Dixon has been flying since he was 16). They take trips to Home Depot, race go-karts, pilot quadcopters, or just drive into the desert in different directions to see what’s there. They order from Jesse’s, one of two pizza joints in town. And the people they do socialize with tend to be space enthusiasts as well.

“Mojave is a whole other world,” says Srirangarajan. “Every other person you meet is into space. There is an actual spaceport where we can go launch rockets into space if we wanted to, tomorrow.”

Model rocketry has been an educational staple for decades. Take a cardboard tube, stick on some fins, a nose cone, and an engine, and you’ve got a rocket.

“Model rockets use the same basic materials that have always been used,” says David Raimondi, president of LUNAR, the Livermore (California) Unit of the National Association of Rocketry. “The two big changes are the complexity and size of the electronics available today, and the availability of motors.”

For at-home model rocketry, many of those motors come from Estes Rockets. They’re the little light-brown cylinders, around the size of a roll of pennies, filled with solid, pressed black powder rocket fuel — also known as gunpowder.

“Business is good. It’s still very popular, but it has changed,” says Mike Fritz, Estes’ director of product development. “Today’s consumers seem to be a little more interested in, I got an hour, what can you give me?”

Estes sells rocket engines up to size G. The engine inside Carbon Origins’ Phoenix 0.3 is size O, sourced from Cesaroni Technology, an industrial manufacturing company in Canada. Since each letter increment represents a doubling of rocket power, the Phoenix 0.3 is more than 8,000 times more powerful than the one you likely launched in middle school.

Any motor larger than a G requires certification from the National Association of Rocketry or the Tripoli Rocket Association, though Fritz points out that, at that level, you’re probably firing rockets beyond what you can see. That’s one of the reasons onboard electronics can be useful. A radio or GPS for tracking means once it goes out of your sight, it’s not gone for good. And an altimeter (usually barometric) can tell you exactly how high it went, something else that quickly gets pretty hard to distinguish by eye.

An O motor provides up to 40,960 newton-seconds of thrust. The O in Carbon Origins’ Phoenix 0.3 is just over the cutoff from N size, with 21,062 newton-seconds — a lot for a 63.4-pound rocket. Enough, according to their calculations, to blast it to that 43,000 foot, Mach 2.5 goal.

There’s a lot of effort going into making better rocket engines. Carbon Origins figured their resources were better spent on optimizing the rockets, and outsourcing the engine. But other teams of students and professionals are experimenting with different fuels. Here are the three most common types:

Solid Propellant: Black powder compressed with an oxidizing agent to provide oxygen, solid engines are designed not to explode but to burn uniformly and expel gases out the back. Some include a charge on burnout to eject a parachute, while others are built to ignite a second stage.

Liquid Propellant: Liquid-propelled engines mix a fuel like petroleum with an oxidizer in a combustion chamber. They’re more complex than solid engines, but can be re-used, as well as throttled.

Hybrid: Typically, the fuel is solid while the oxidizer is pumped in, allowing for uniform burn and throttling.

The engine doesn’t push the rocket the whole way; at around 6 seconds into the flight, says Srirangarajan, it should run out of fuel. But it’ll still be traveling more than twice the speed of sound, and that momentum will carry it a great deal further, for another minute or more. As it reaches its peak, the onboard controller will recognize that air pressure has stopped changing, and deploy the CO2 charge that will pop the rocket open and eject the drogue parachute. This smaller chute will allow the rocket to descend quickly to an altitude of a few thousand feet, where a main chute will deploy to soften the landing. By the time it touches down, it should be going a nice, easy, 10mph.

That wasn’t quite how it worked out for predecessor Phoenix 0.2. Launched in June 2014, its chutes deployed while it was still accelerating. The nylon strap tore through the aluminum body, and the rocket came down ballistic — in free fall. They recovered the warped, crumpled body, which stands near their kitchen beside the scale model. The flight controller showed that the air pressure remained constant, suggesting that the small hole in the rocket that allows pressure to equalize as it flies might have gotten plugged somehow. When the altimeter can’t read the pressure change, it doesn’t know when the rocket peaks, and therefore when to release the chute.

“Rockets are hard,” says Shara, noting that in Phoenix 0.3, they’ve included redundant flight controllers and parachute ejection charges.

Phoenix 0.2’s crash was just one of many things that can go wrong with rockets. The FAR site is run by a group of mentors from the rocketry industry, who allow university clubs to use it, and companies to launch for a small fee. Kevin Baxter, FAR’s president, helped buy the land after he saw a need for a place students could go to launch rockets. The site lies under the Edwards Air Force Base umbrella, so there are no commercial flights going over. In 2003, FAR was founded as a nonprofit.

Students from all over southern California, the Southwest, and even as far as Annapolis, Maryland, launch twice a month at the site. Failures, sometimes including spectacular explosions, happen frequently. “Failed launches are simply learning experiences and they are a common occurrence at FAR,” says Baxter. “Hence the viewing trenches and blockhouse.”

On Saturday, about 24 hours before Carbon Origins was scheduled to launch, a rocket crashed. It was silver, red, and white, liquid oxygen-fueled, with a 3D-printed engine and a wide set of fins. It lifted off slowly, almost hovering in midair. It tipped sideways into the wind, flew a few hundred feet, and hit the ground with a thud and a plume of dust.

Other rocket engineers were quick to point out what may have gone wrong. The launch rail was short, one said, especially in relation to the large fins. With a short rail, the rocket doesn’t achieve as much speed before it’s free, and with large fins, it’s liable to tilt into the wind, like a weather vane.

It’s a problem with stability, which is primarily dependent on the distance between the center of mass (determined by weight) and the center of pressure (determined by airflow over the shape of the rocket, especially the fins). The farther the two are apart, the more stable the rocket. The large fins meant the wind had a greater influence on that part of the rocket, thus bringing the center of pressure toward the rear, far from the center of mass, and causing the rocket to be dangerously “overstable.” Boom.

Originally, Carbon Origins just wanted to make the best rocket they could. But they realized that that rocket needed a brain that wasn’t available yet. So while other space startups and rocketeers are experimenting primarily with engines and the rockets themselves, to Carbon Origins the rocket is the vehicle — literally and metaphorically, says Shara — by which to launch the Apollo controller. (A mailing list currently allows you to reserve one, and more than 5,000 people have done so. Two versions are planned, entry-level and pro.)

“The electronics is such a huge part of launching a high-power rocket,” says Shara. “It’s not important in little rockets, but in big rockets it’s all about tracking and data and all of the different equipment and electronics and cameras on the rocket.”

“It’s a very extreme environment, it really gave us an opportunity to build something at a very high level,” she continues. “We’re building something that can exist and work in an environment that would be probably beyond a lot of people’s projects.”

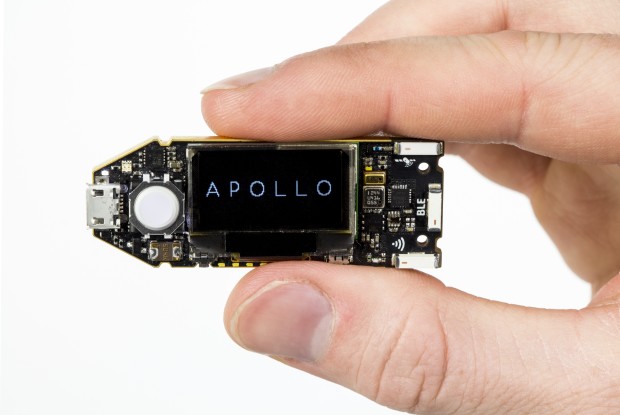

The board is built with flanges that draw heat to the gold-plated edges, making Apollo act like its own heat sink and RF shield in one. Sensors are delicate where heat is concerned, so this layout means components can be placed closer together, allowing them to mash 11 sensors onto the tiny board.

A 32-bit ARM Cortex-M3 processor runs GPS, Wi-Fi, and Bluetooth, as well as accelerometer, magnetometer, pressure sensor, infrared and ultraviolet light sensors, and more. The face of the approximately 1″×2″ board is largely covered by an OLED screen and a trackball to toggle through apps and data.

With its tiny size and myriad of sensors, Apollo is unique within rocketry, but it’s also unique among boards in general — it has attracted potential users far outside rocketry, including wearables, drones, and Internet of Things devices. The Void, a virtual reality arcade near Salt Lake City, is building a VR gaming environment in a theater. Each gamer wears a vest, helmet, and gloves equipped with sensors based on Apollo to track their motion. DomeCandy Labs, a portable speaker maker, is using Apollo’s communication capabilities to prototype a Bluetooth speaker that will offer feedback tailored toward music.

Carbon Origins is so bullish on this thread that they’re spinning off Carbon Labs, which will mimic Carbon Origins’ approach to democratizing space, but for data sensor hubs — i.e., making it easier to use Apollo and its components to meld the physical and digital worlds and enable the Internet of Things. Carbon Labs will offer custom-built products based on Apollo architecture; that is, they’ll work backward from Apollo, picking the relevant parts and software for each client, greatly reducing the time required for development, according to Srirangarajan.

Both aspects, the controller (and its potential use in the Internet of Things revolution) and the rockets themselves, are important to Carbon Origins’ mission.

“I can’t choose sides,” says Srirangarajan. “I spend almost the same amount of time on both, they’re like my two babies.”

They’ve made it this far without any outside investment, relying on savings and funds from other successful startups they’ve been involved with. “Now that we are cash-flow positive, we don’t have an immediate requirement,” Srirangarajan says. “But it is in our roadmap.” Once Apollo launches as a product, they’ll explore venture capital.

Unlike the Mojave, Case Western Reserve University is not a great place to launch rockets. Still, upon arriving as a freshman, Srirangarajan quickly founded the rocketry club. And a robot club. It was robotics that first hooked him, as a boy living in India, where his mom was a computer engineer who made him learn programming as a kid — BASIC, Java, C. He used to visit a friend of his grandfather’s in the country, who had bought a bunch of land after retiring from the Indian navy. Together, they experimented with solar pumps and irrigation. “I used to go there in the summer, and it used to blow my mind, the things you could do with electronics,” says Srirangarajan. He built his first robot sometime around age 11, with the help of that friend.

“It’s kind of been part of a pretty hard education system, with this insanely cool outlet during the summers. That combination led me to build flame-throwing robots and laser harps and all these really cool Maker projects that not a lot of my peers were really into,” he says. That led him to entrepreneurship: “I made stuff, I sold stuff, I made money that helped me make other things.”

Robotics led Srirangarajan to space — after all, robots are frequently crucial parts of space missions — and space led him to his co-founders.

Torio, Carbon Origins’ COO, was born in the Philippines, and joined up simply because she loves space. “I found out really young that that’s what I wanted to do, I wanted to be an astronaut. And that just never left me,” she says. “Going the whole NASA route is so tedious, there’s no surefire way of getting to what you want to do.”

Rocket club was an exception to the rote tedium of PowerPoint classes: “There’s this exciting thing that you can actually participate in, actually put the theoretical stuff you’ve learned into practice, which was amazing.”

“College isn’t right for everyone. That was definitely the case with me — I hated it,” she says. “I’m a mech-e, I graduated as a mech-e, I did not see anything hands-on until senior year.” She skipped graduation to go to a robotics competition in Florida.

While Torio skipped graduation, Shara left school entirely to start Carbon Origins, acting as vice president of electronics. “You don’t get great opportunities like this that come along very often,” she says. “It was starting to extend beyond the scope of what was possible financially, in terms of resources, and beyond that, acceptable in a university setting.”

The decision wasn’t out of character for her. She was highly recruited by the engineering school, says dean Jeffrey Duerk, who describes her as “exactly the type of student you want at the university.” She quickly became a TA and a leader among her peers. Later on, when her grades flagged, he discussed it with her. “She said, ‘I came here to learn, I didn’t come here to get good grades.’”

Shara has been immersed in electronics since almost before she could walk, when her father gave her a scrap circuit board. “As soon as I discovered I could find these circuit boards in everything, all the household appliances, our house kind of became the e-waste central of my hometown,” she says.

She admires Arduino, and cites it as inspiration for Carbon Origins. “We’ve come such an incredibly long way, in terms of electronics, that things that are possible or would take financial inputs that only governments can provide, now you can basically order it on Amazon and have it on your doorstep in a couple of days.” That’s what ties the rockets to the board: the goal of democratizing access to space.

Shara and Dixon both grew up firing little rockets with their dads — she in Montreal, Canada, he in Ann Arbor, Michigan. Dixon couldn’t wait to move on to bigger, faster, higher rockets; now he’s vice president of aerospace for Carbon Origins. The more advanced he got, the better he liked it. “Once you start getting into harder materials, like aluminum rockets, and making your avionics a lot more advanced, getting data off of them, that’s when the real engineering starts,” he says. “That’s when the problem solving starts. That’s what really drives me.”

Now they can relive their flights virtually, thanks to the data collected by Apollo. “We like great tools that potentially streamline our engineering, so we built Apollo as a Swiss Army knife for Makers and developers,” says Srirangarajan.

After a second countdown, Phoenix 0.3 achieves ignition. It roars off the launch pad, but somewhere around 3,000 feet the team loses radio contact with it. It goes unstable, spiraling upward in a corkscrew fashion for a few seconds before breaking into pieces near the 10,000 foot mark. The heavier parts tumble down just outside the FAR compound, while the main chute breaks away and floats off to the south.

The Carbon Origins crew wanders out of the bunker, watching the carnage, while Dixon, still on video, asks what happened and where everyone went.

“That’s disappointing, I suppose,” says Srirangarajan. “But I have a track on a few parts, which means data, and data is good. It’s okay, failure is good, because we’ll learn.”

Some of their simulations showed oscillations a little before Mach 2, Srirangarajan says as he combs the desert for rocket parts, marking the GPS points of each one so he can re-create the debris field on Google Maps. Too much oscillation could have caused the composite body to snap, releasing the parachute, and the drag could have cause the spiral. But that’s a guess; to find out, they’ll have to locate the flight controllers, which seem to have floated off with the main chute.

Those three Apollos and six commercial flight controllers were housed partially in the nose cone, partially in the body. But when Srirangarajan finds the nose cone, it’s empty, embedded tip-first in the sand. The wreckage of the lower half of the body lies not far away, black aluminum fins bent to the side. The electronics bay is there, still beeping, but it contained just a pair of radios and three off-the-shelf flight controllers. “This really gives you an appreciation for the strength, and the forces,” says Shara, holding it up.

“Rockets are hard,” she says again. “It wasn’t, certainly, a complete failure.” If they can recover the Apollos, the data will tell them what went wrong. And with luck, they can still compare the data between Apollos, and from the commercial controllers, to see how accurate the board is.

Attached was a green payload board, carrying one Apollo and three commercial flight computers. Apollos talk to each other, notes Srirangarajan, so if they can get data off it, they’ll have a successful mission after all. But it’s got a cracked screen and the SD card may be damaged; they can’t risk ejecting it until they know for sure. Instead, they plug the board in and arm it as if the rocket were still whole. It shows up as an external drive, and they download the CSV file. Combined with high-speed video and the data from the commercially available boards from the electronics bay, this gives them a picture of what happened.

Only 1 second after takeoff, Phoenix 0.3 starts to roll — i.e., rotate around its vertical axis — at more than twice the expected 0.5rpm rate. It goes supersonic, and its records show greater than expected thrust. By 2 seconds in, the roll rate has reached 20rpm. That wouldn’t be such a big deal, but combine roll with a little tilt and a little vibration, and you start to spiral.

It hits nearly Mach 2 before it splits apart. The parts decelerate, but continue to shoot upward until about 10,000 feet, when they reach apogee and start to tumble back to Earth. It takes less than 4 seconds from launch to shred, and around 10 seconds to maximum height. “Three seconds is an eternity in rockets,” Srirangarajan says later.

By the time they’ve put this timeline together, Carbon Origins has reached a decision. They’re saying goodbye to the house, goodbye to California City, and moving to an actual office in Palmdale, closer to Los Angeles. They’ll still launch rockets at the FAR site, still travel together, work together, even live together, but they’ll no longer share a living room with a drill press and a shop vac. The new space will allow them to expand, recruit new employees, and move on. They have a two-stage launch scheduled for September, shooting for 180,000 feet. Phoenix 0.3 may not have reached the apex they hoped for, but Carbon Origins is still ascending.

Going Further

Interested in fueling your inner rocket scientist?

Check out our book Make: Rockets, from the Maker Shed. Learn the aerodynamics that influence how they fly, and try DIY projects from simple water rockets to two-stage payload carriers.

One of the best ways to get started is to check out a local rocketry club. Most cities have them, so find the one nearest you.

ADVERTISEMENT