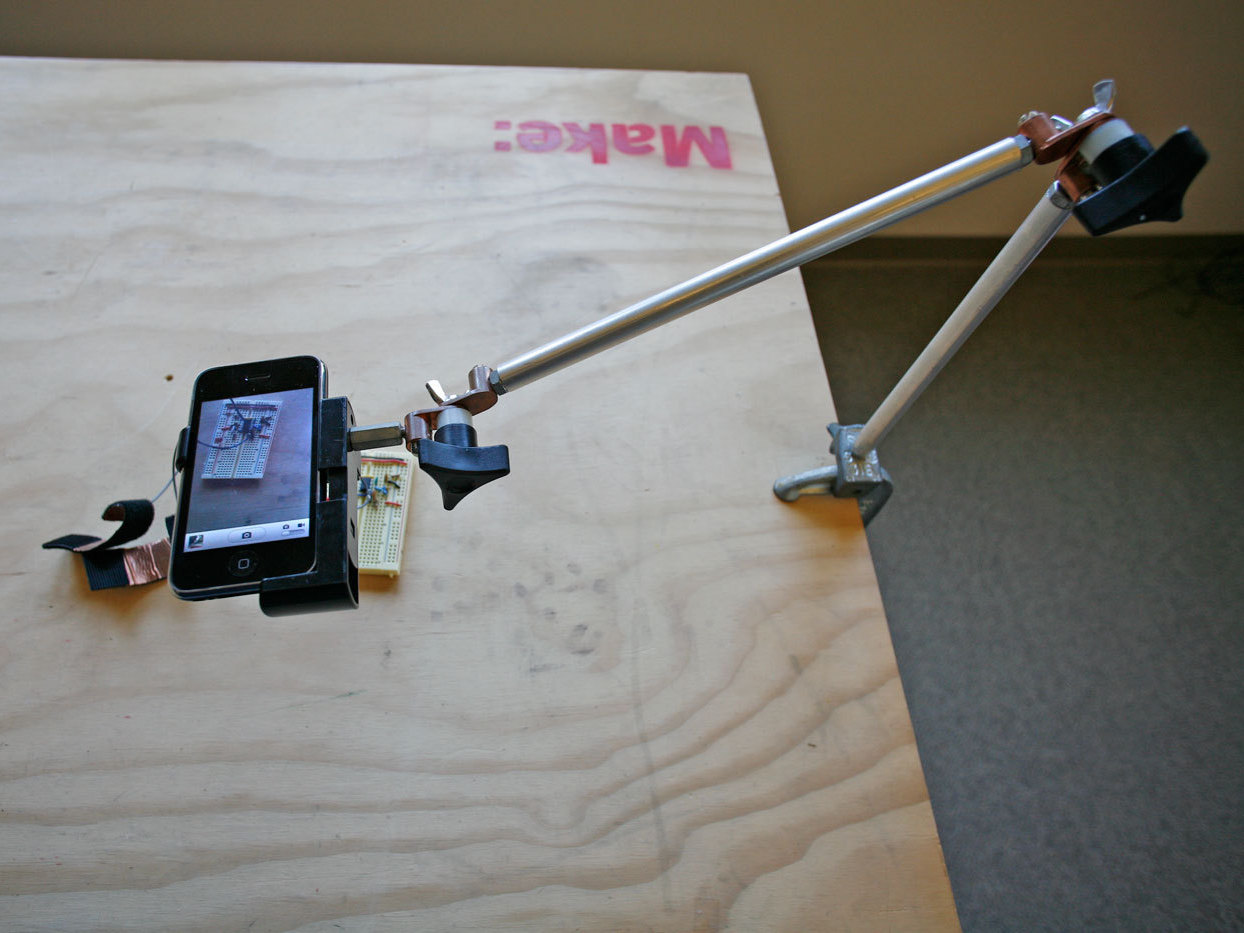

If you’re familiar with tabletop product photography and video, you know what a pain it can be to shoot overhead shots while working on your subject. Tripods just get in the way.

The usual remedy is a document camera, the modern equivalent of the overhead projector. These cameras let you display close-up shots with an LCD projector or external monitor, and they cost between $500 and $1,500. They’re well suited to capturing images of document-sized objects, but come on, a grand for a glorified webcam?

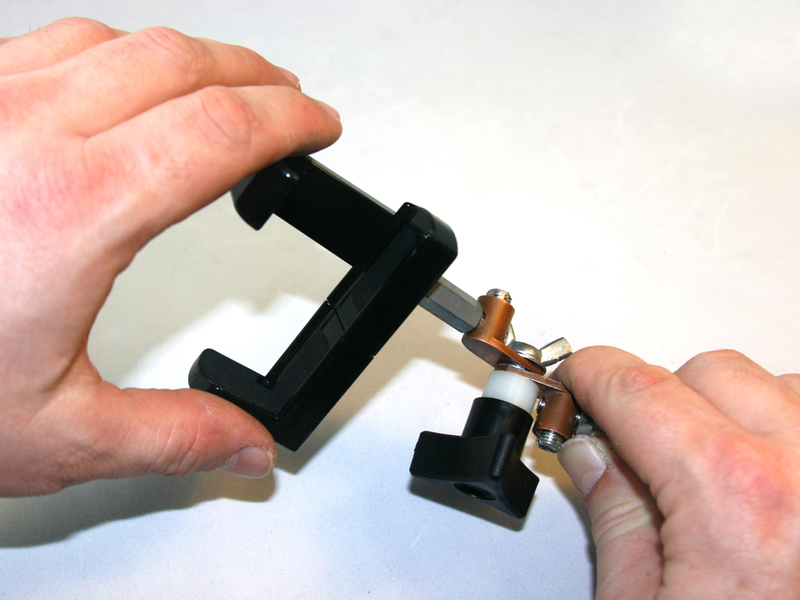

We’ve all got streaming video on our smartphones now, so couldn’t we just use that instead? The problem is, how to hold it over the project without a tripod to bump into.

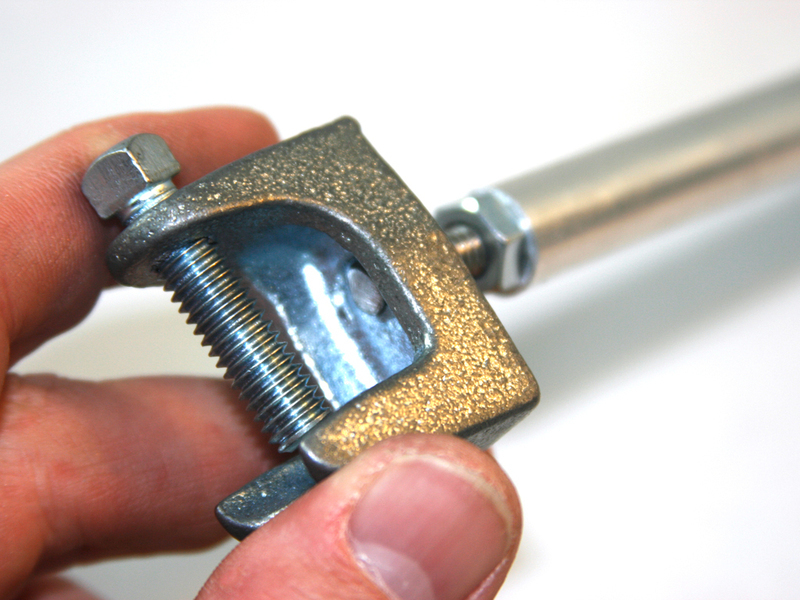

Hollywood grips solve this problem with what is known as a gobo arm, a lightweight mount that lets you position your smartphone (webcam, etc.) down where the action is without getting in the way. Commercial units run $100–$150, not including the $30 clamp you attach it to. But for the price of one of those fancy clamps, you can piece together your own Mobile Document Camera Stand using easily sourced parts.

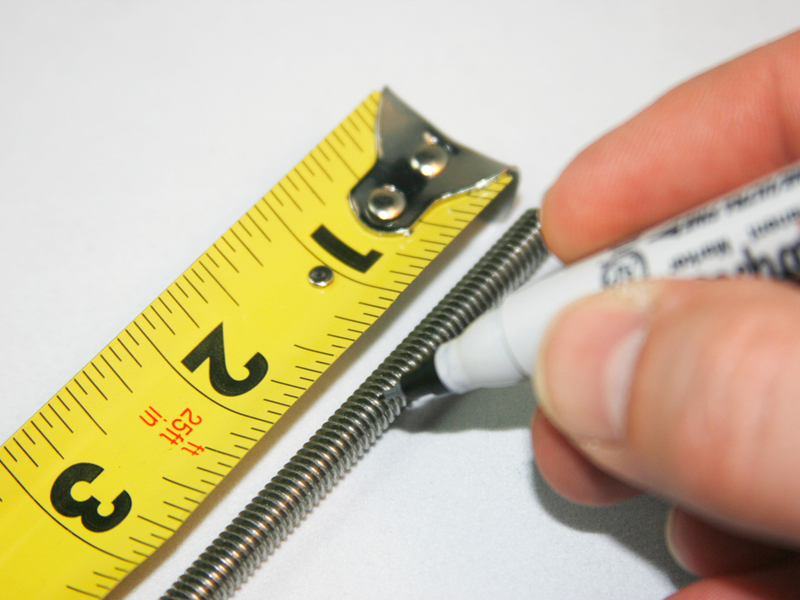

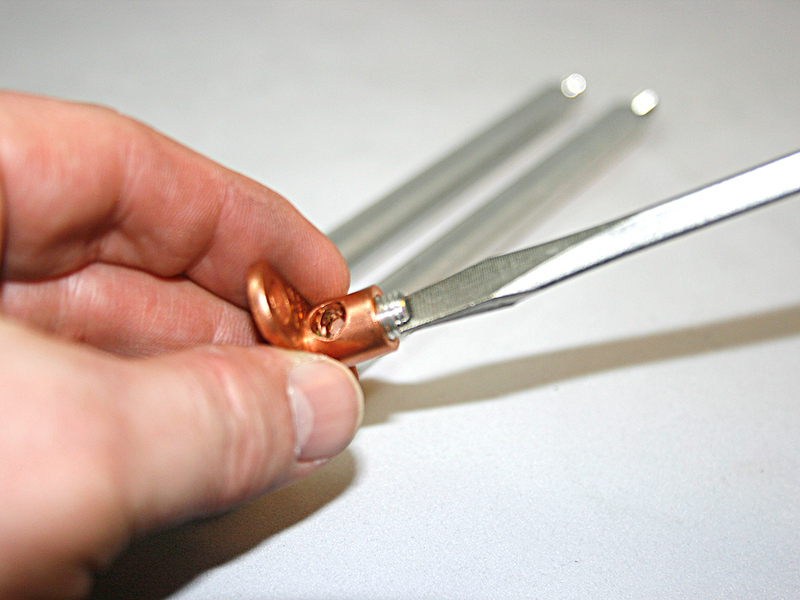

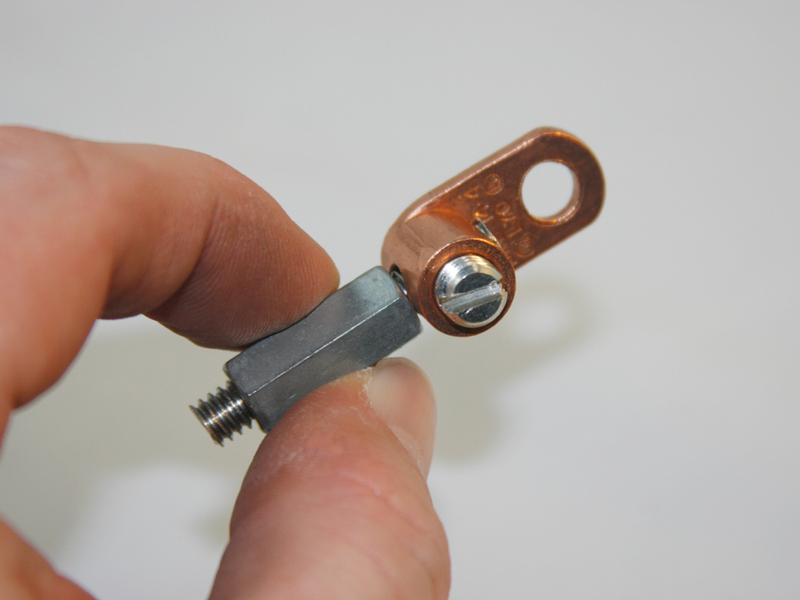

It’s easy. If you can make cuts with a hacksaw, you can build this project. There’s also plenty of room for improvement. For example, I recently upgraded the lock washers to the “curved disc spring” type, and they work great.