I got the idea to build this last year when I read an article about hovercrafts. After studying the topic further I wanted to build one for myself.

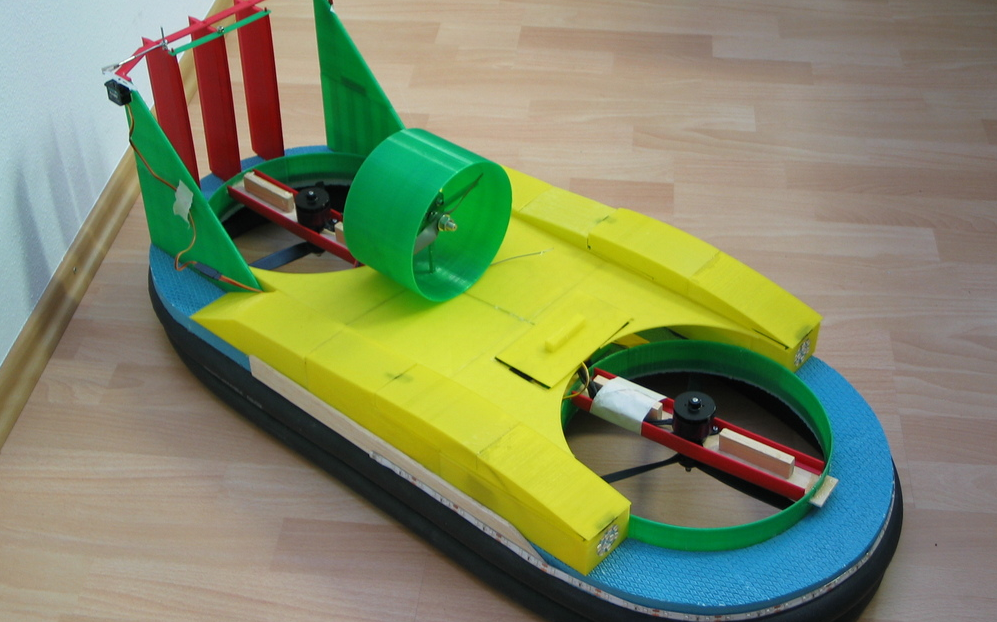

This is my third prototype. Previous versions were difficult to control and had a hard time carrying weight and keeping debris away from the lifting motor. I designed this using Autodesk Inventor 2013 and a MakerBot Replicator 3D printer. It took around 3–4 days to fully print the final design of the hovercraft.

The base is not printed because it would take way too long. Plus, Styrofoam has the advantage that it swims when the engines fail. I also did not print the bicycle tubes because they have to be flexible and they must be one piece so that no air flows out to the sides.

The Hovercaft is lifted by two motors and it has one thrust motor. The power for the motors comes from three 2800 mAh LiPo batteries.

My plans with the Hovercraft are to develop a cheap mobile research station for the arctic. The advantages are that it has no CO2 emissions and you can control it from a remote location, like a drone.

You can find the required STL files for this project on Thingiverse. The following steps will provide you with the information you need to assemble the printed parts, wire the electronics, and configure the R/C channels.