By Molly Graber and Chris Merrick

Have you ever dreamed of being really tall? Walking on stilts is a fun and adventurous sport. But where are you going to get a decent-priced pair of stilts to try for your first time?

With these instructions, you can add as much height as you want and not hurt your wallet in the meantime. All you need is the know-how to use some simple tools — or a friend who can help!

Building your own pair of stilts ensures that they’re made just for your body, and when you’re done you’ve learned another crafty skill. Then all you’ll need is someone to help you learn to walk tall — and also how to fall. It’s a blast and we highly recommend it. Stilt walking can be as easy as it looks.

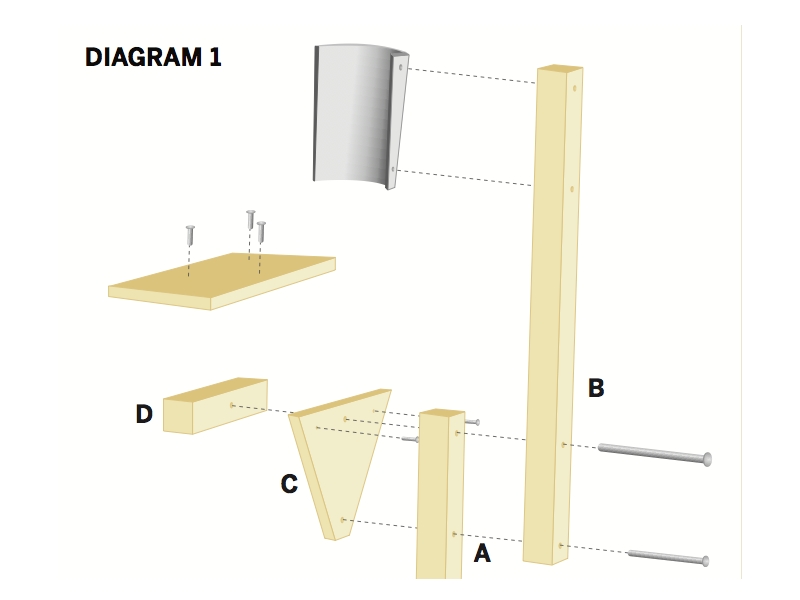

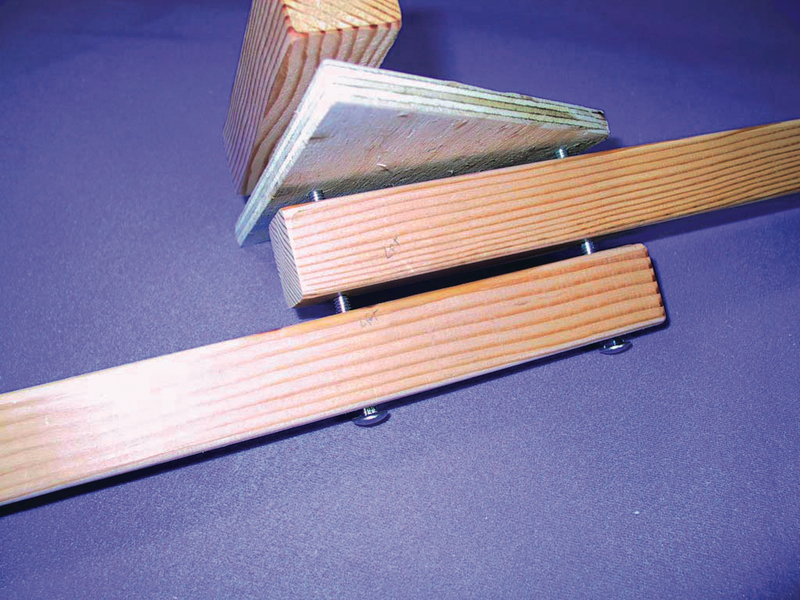

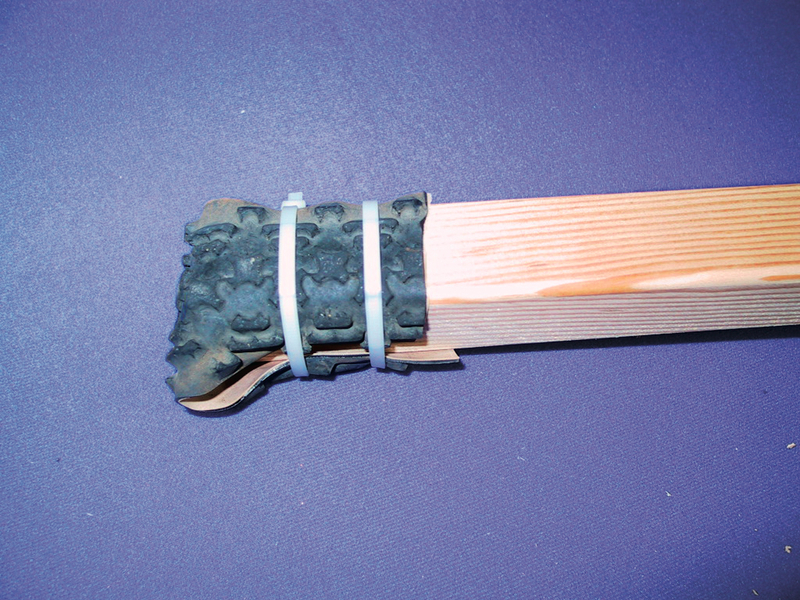

For starters, check out an animated version of how the pieces fit together.