This project is part 2 in the building a robot arm tutorial. In the first part I show how to design the robot arm and in the third part I show how to design the mount section. Part four will show how to add control with an Arduino.

In part one of making a robot arm, we explored a lot of things like 3D computer aided drafting software, or CAD for short, and 3D printing. We also explored how to design things that will interface with real world objects, like our stepper motors. Still, we only built out one small part of the robot, the core section that gives the arm reach and good articulation. Obviously this small section of a robot alone can’t do many cool things so we need to add to it. Using the tools that were discussed in my previous post, the CAD software and its ability to create digital forms, we will generate more parts that interface with the motors and the section of the arm we already designed.

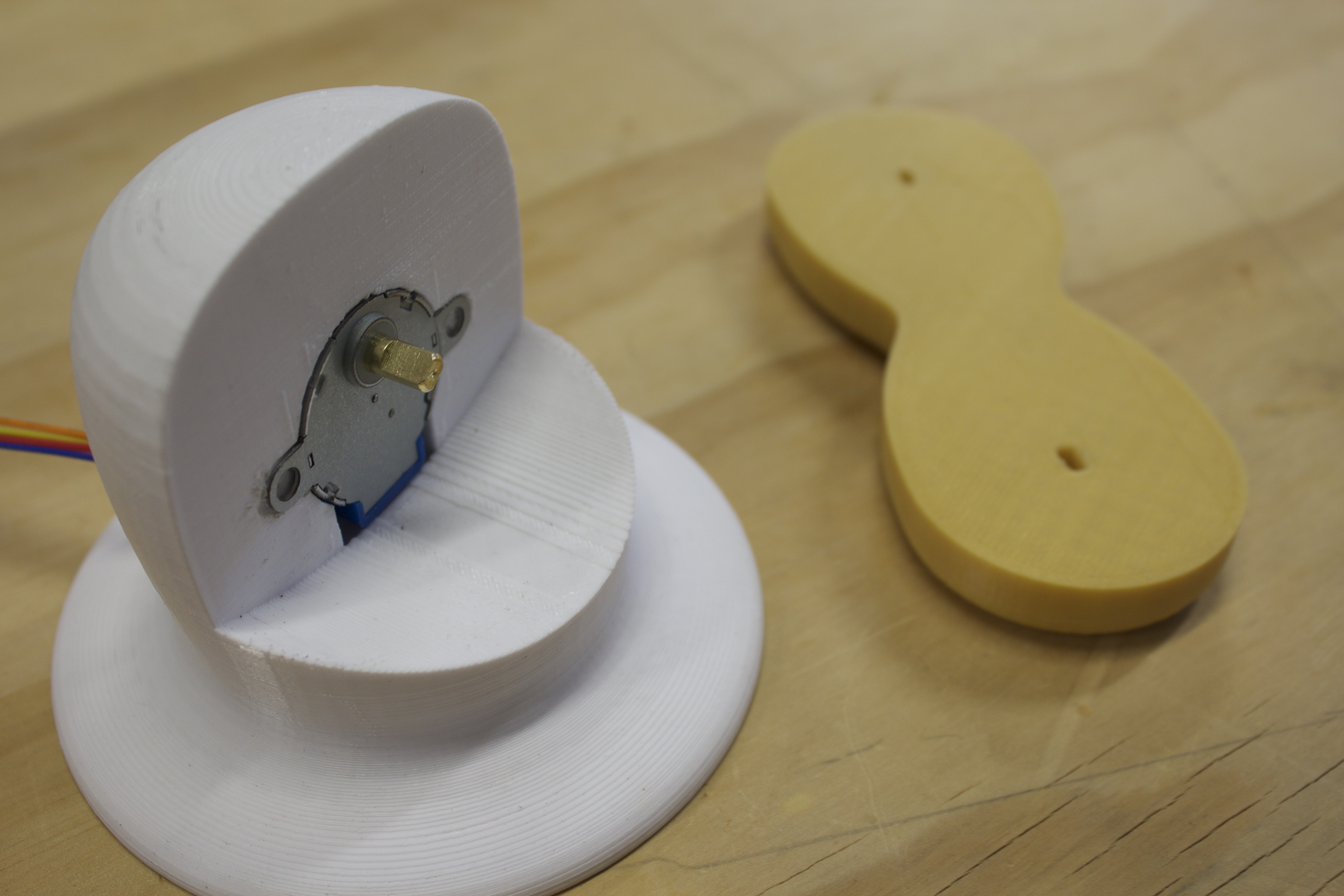

The first addition is the base. In this tutorial, we will go over how to create a base for the robot arm and how to shape the base structure so that it might accommodate one of our stepper motors. We will cover a number of new digital CAD tools including how to create perfectly round structures that fit our needs and how to integrate the motor into the base to support the robot arm.

We will again be using the Dremel Idea Builder because of its reliability and speed.

As we continue to design and build this arm, there is opportunity to add and modify the function and structure of the robot. Once we lay the groundwork for how to design all the critical pieces and get it moving, we will be able to change the design to fit particular use cases and functions. This includes being able to scale the arm to use bigger motors and move large objects. Still, we will need to to make sure all of our component parts work before we start experimenting.

One more thing to keep in mind, as we design make sure to save and make copies of all your files. If we do go back to edit and change our designs, then copies will allow us to make lots of different versions and iterate on our ideas.