The Scientific Revolution was a momentous time. Most historians of science agree that during this era — 1500 to 1700 CE — people started thinking differently, more scientifically, about the way the world worked. Many began to think of the world as being an orderly machine, one in which laws and rules controlled the way nature worked. Although scientists, or natural philosophers as they were then called, did not necessarily know exactly what these laws were, they were certain they were there, working behind the scenes.

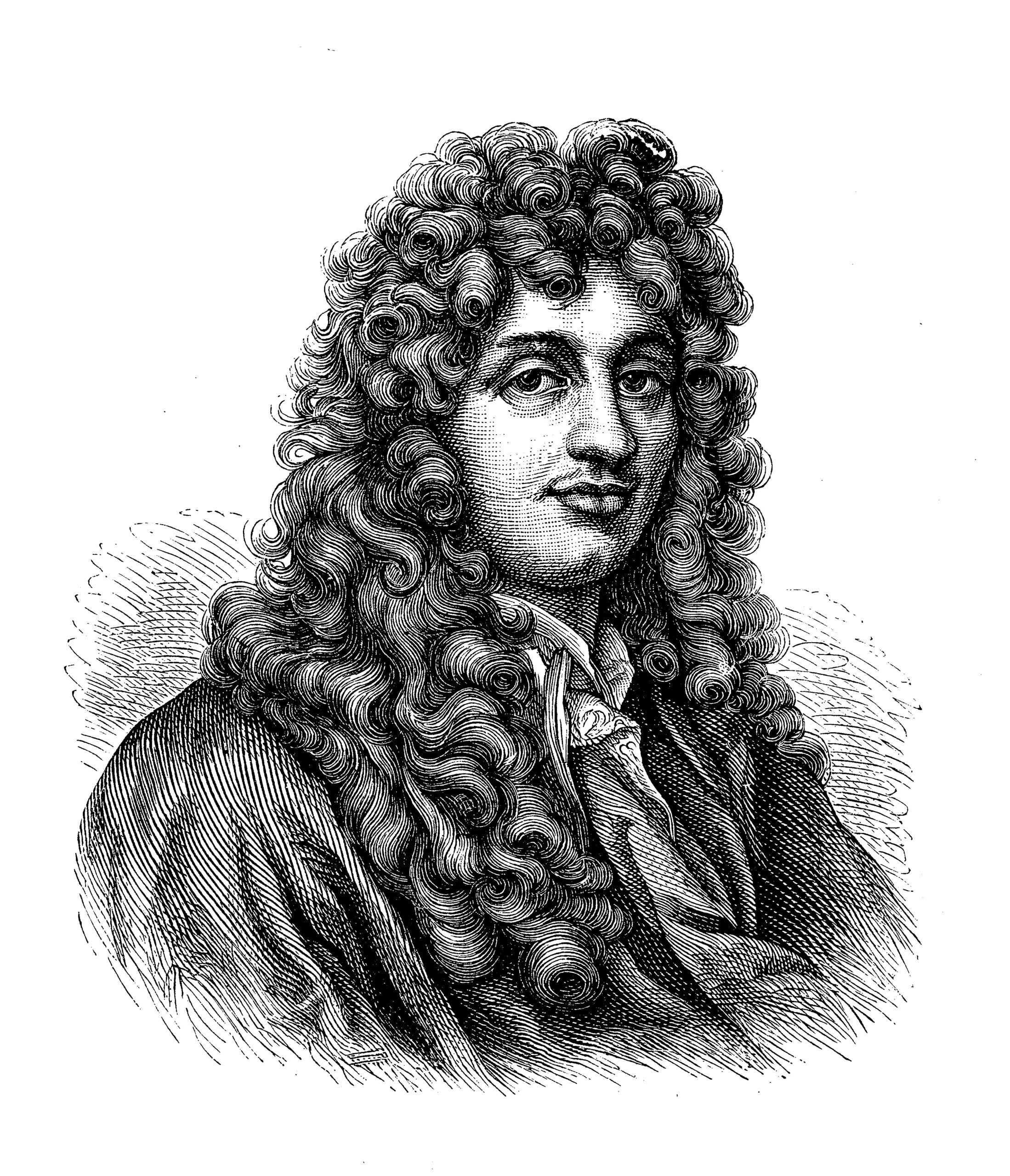

The superstars of the Scientific Revolution were Galileo, Copernicus, and Newton, but there were a number of other important thinkers as well: Robert Boyle, Johannes Kepler, and Rene Descartes, to name but a few. Often overlooked in the crowd of luminaries is the great Dutch scientist Christiaan Huygens. Huygens first made sense of Saturn’s rings; discovered Titan, the largest moon in the solar system; laid the groundwork for the physics of Isaac Newton; and designed and built one of the first vacuum pumps (see my article “Robert Boyle and the Air Pump” in Make: Volume 78.) But arguably, his most significant and practical invention was the pendulum clock.

At the time Huygens lived, from 1629 to 1695, clocks were becoming increasingly important in daily life, but they were very inaccurate. The best of them could do no better than gain or lose more than 15 minutes in time every day. While a clock like that could tell you when it was time to eat lunch, it was not suitable for navigation or astronomical observations.

Inspired by Galileo Galilei’s investigations of pendulums about 75 years earlier, Huygens began thinking about how he could use pendulums to keep better time. Huygens knew that Galileo had found that pendulums had a fascinating property: they were isochronous, meaning that the time it takes for any single pendulum to swing back and forth is the same no matter how high the point at which the swing begins. This made them useful for keeping time because for a given pendulum length, the time interval for the swing back and forth is always the same. When Huygens substituted the constant-swing-rate pendulum for the imprecise balance wheel used up to that point, the error rate of a Huygens pendulum clock shrank from 15 minutes a day to 15 seconds a day! This was indeed a scientific revolution in timekeeping.

In this edition of Remaking History, we recreate a Huygens-style pendulum clock escapement. An escapement is the heart of any non-electronic clock. It’s the mechanism that goes “tick-tock” and actually keeps time. Because Huygens’ original clock requires accurately cut gears which are difficult to make, we will instead build a simpler descendant called a single-pin escapement clock. The single-pin escapement isn’t widely used by clockmakers, but it certainly keeps time, is easy to build, and makes a loud and satisfying tick-tock when you get it to work.