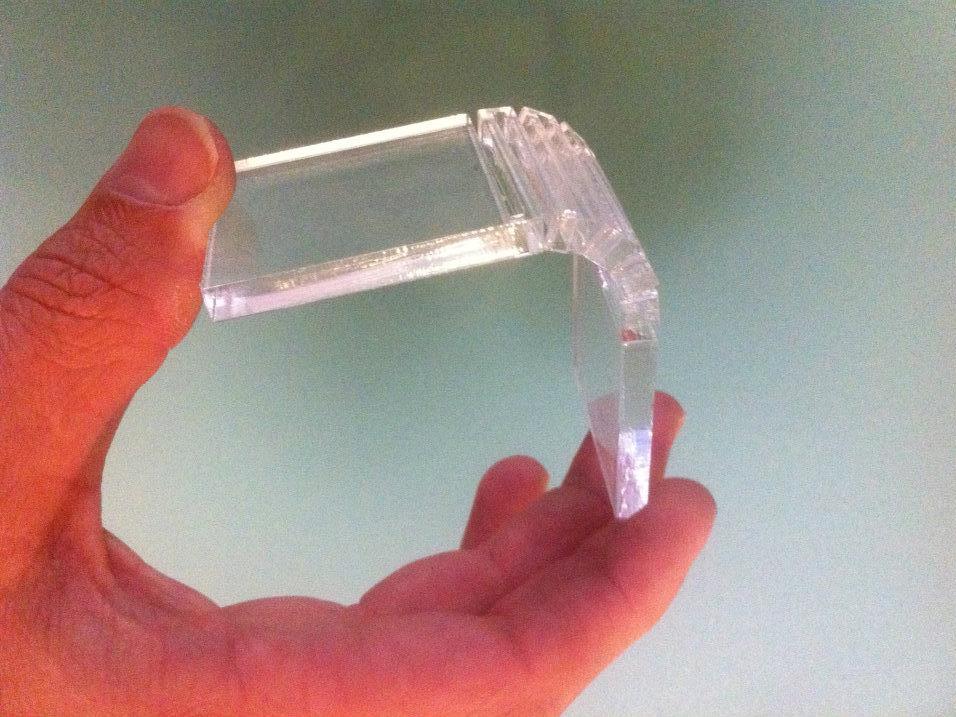

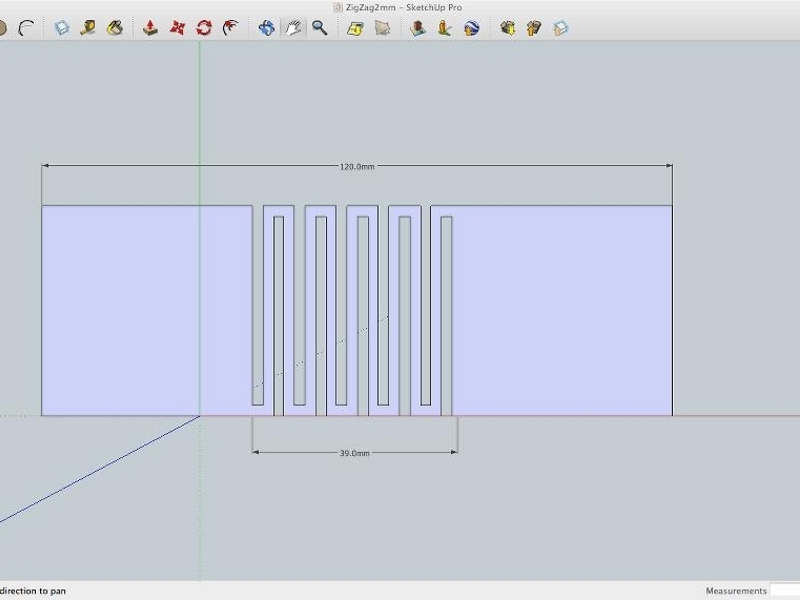

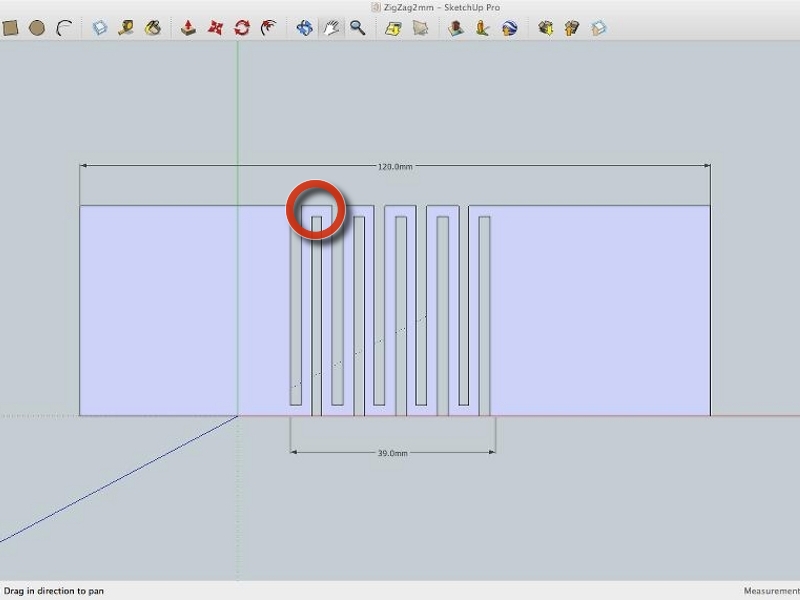

I have a particular interest in discovering new ways to push the limits of material fabrication with my laser cutter. In this guide I’m going to give you an overview of living hinges that will allow you to make bends (and springs!) in a single piece of rigid material. Wood and acrylic are particularly amenable to this technique, and the result has an artistic aspect that’s pretty cool as well!

More importantly, I’m going to try to add a bit of theory to this so that you can extend these techniques in new and better ways.