Snowfall is often just measured by its depth in inches (or centimeters). But there are other important factors to consider. The density, the temperature, and the crystal shape all greatly affect how the snow behaves when you try to work with it. So it might be useful if we also measured other properties of snow as well.

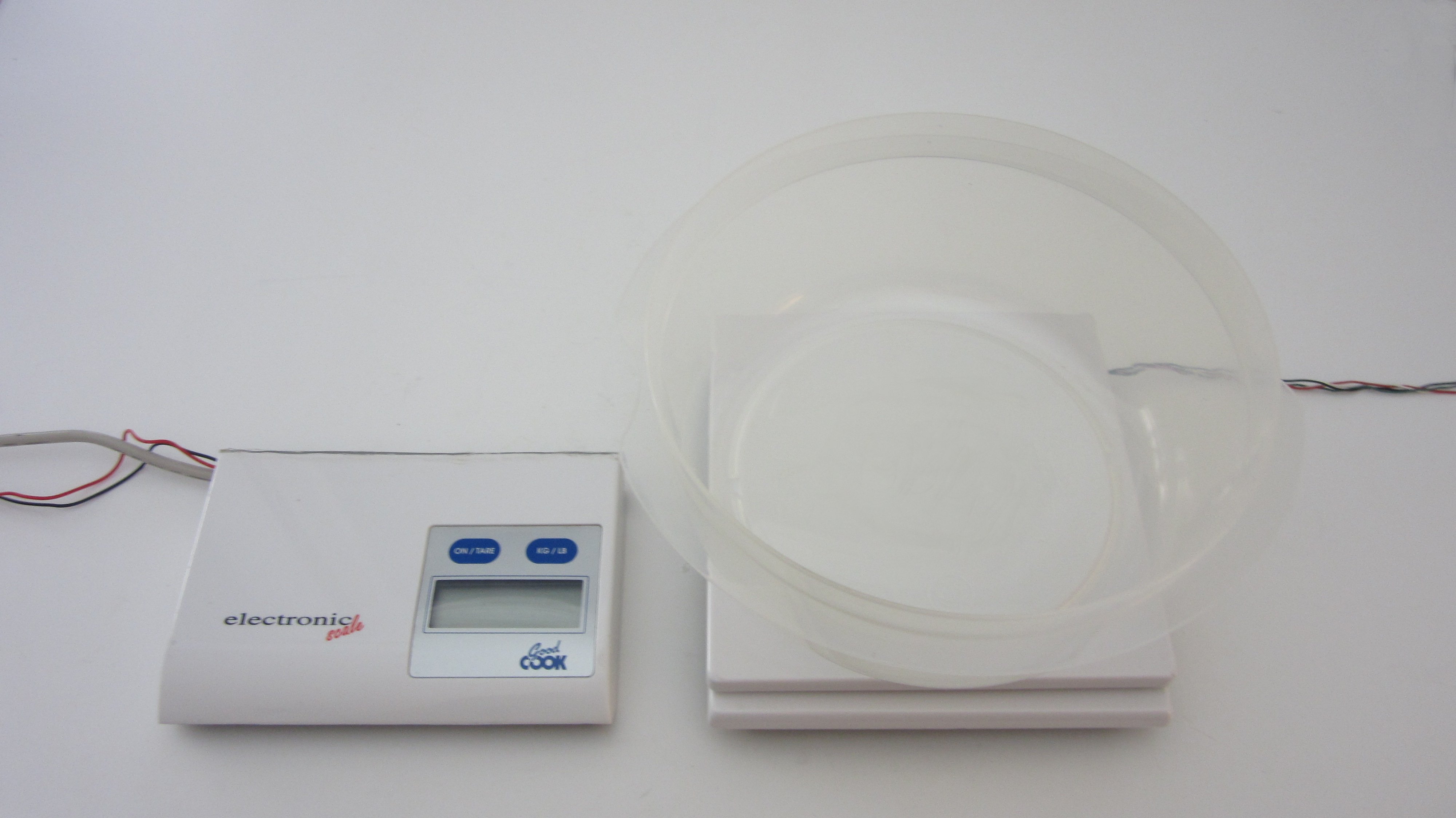

For instance, if you have to shovel snow, the thing that you are most concerned about is the weight of the snow. To measure this, I made a simple scale that can be read remotely. This lets you monitor the snowfall from the comfort of your warm house. It makes a great addition to any DIY home weather station.