If you’re like me, you’re the bane of hardware store employees. I wander through the whole place picking up everything, looking at possibilities more than parts. Can they help me find anything? “No thanks,” I answer. What am I working on? “I don’t know yet,” I say. They move on, keeping a suspicious eye on me.

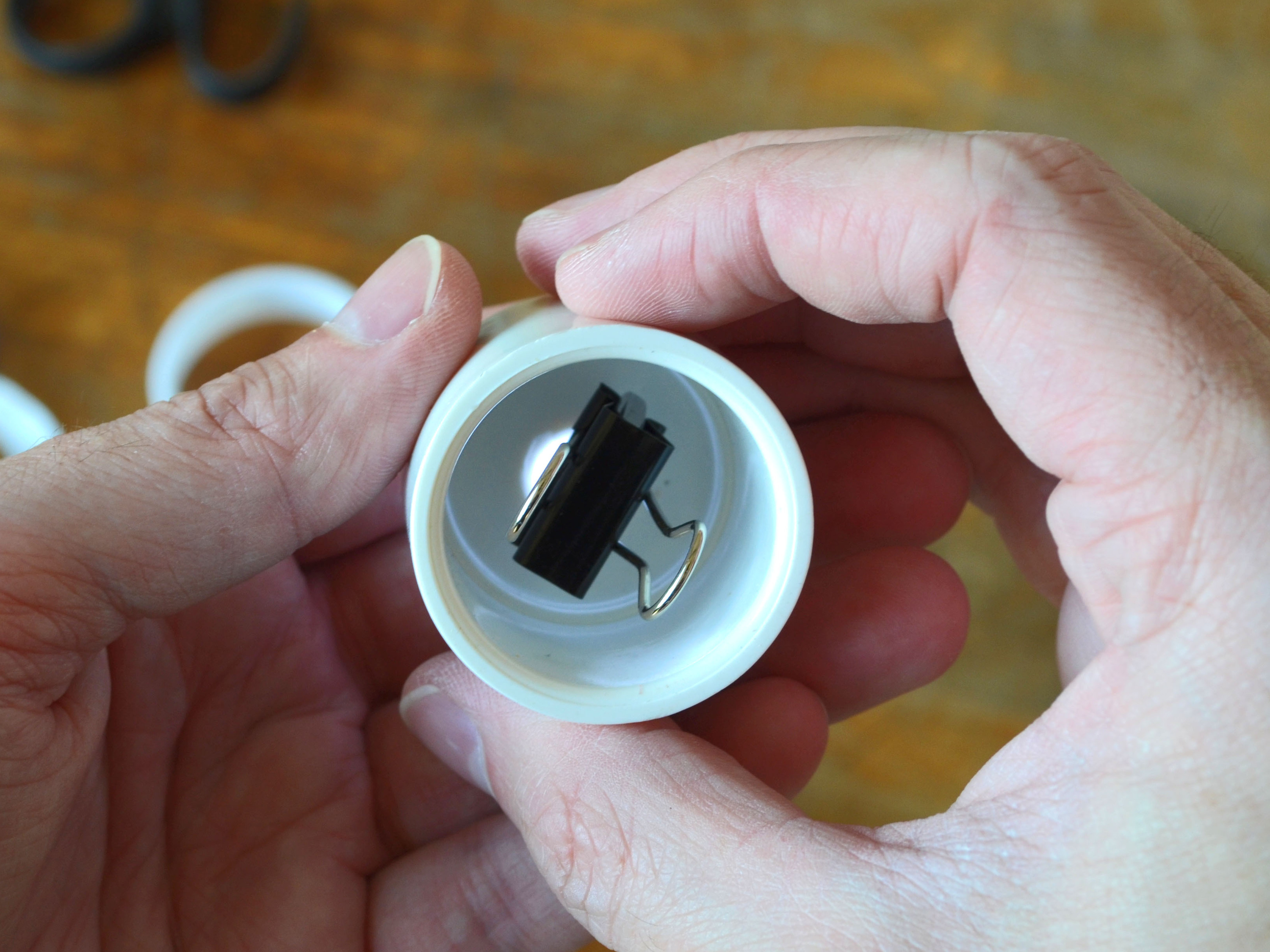

Some things just seem useful, even if I can’t think of how at the moment. One time I found matched pairs of PVC caps and plugs that fit together into little airtight pods of various sizes. For what, I didn’t know until I wanted a way to float lit LEDs down a stream.

The result: simple, rugged, floating LED lanterns that glow for days. They’ve survived being submerged for a week, frozen, and laundered in the washing machine. I even hit one with the lawn mower, and it still works. When they get dirty, just hose them off.