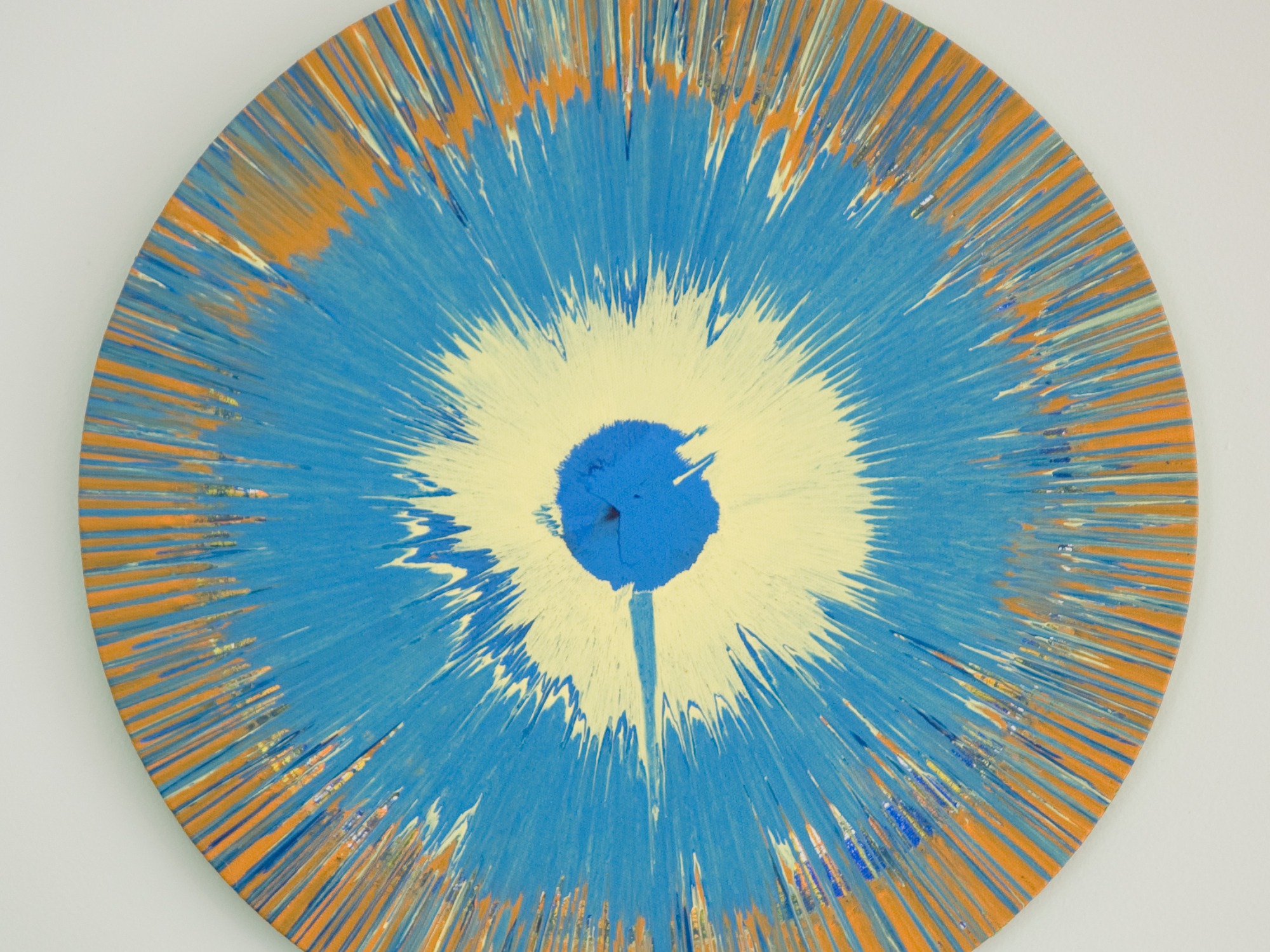

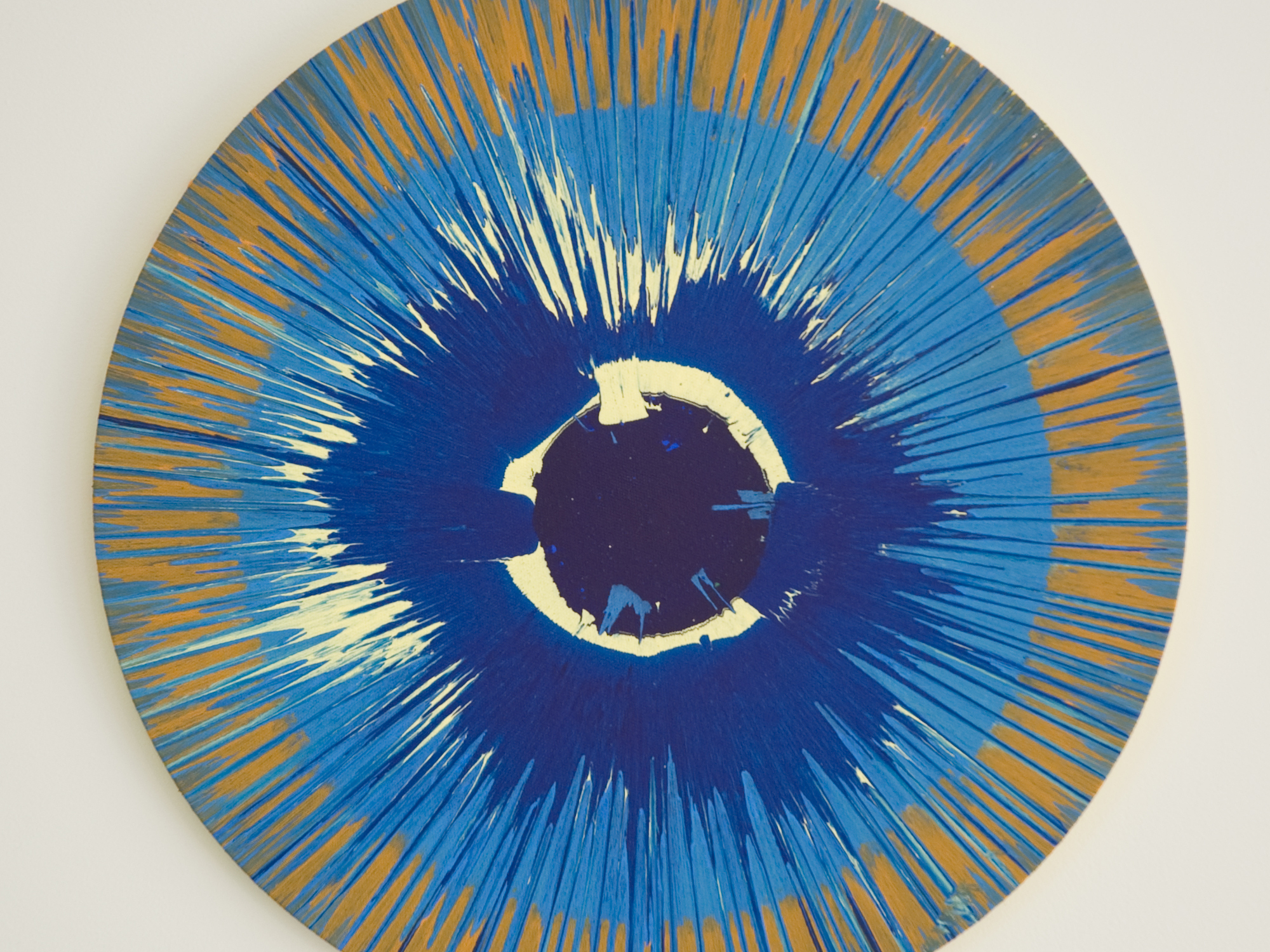

Spin art is a children’s activity, often found at school fairs. Kids drop paint onto a spinning square of paper, making beautiful, colorful patterns. As adults, we imagined it would be fun to scale this up, and up, and up. Our friends envisioned injuries, or worse — an elaborate, spinning contraption flying high into the sky and disappearing.

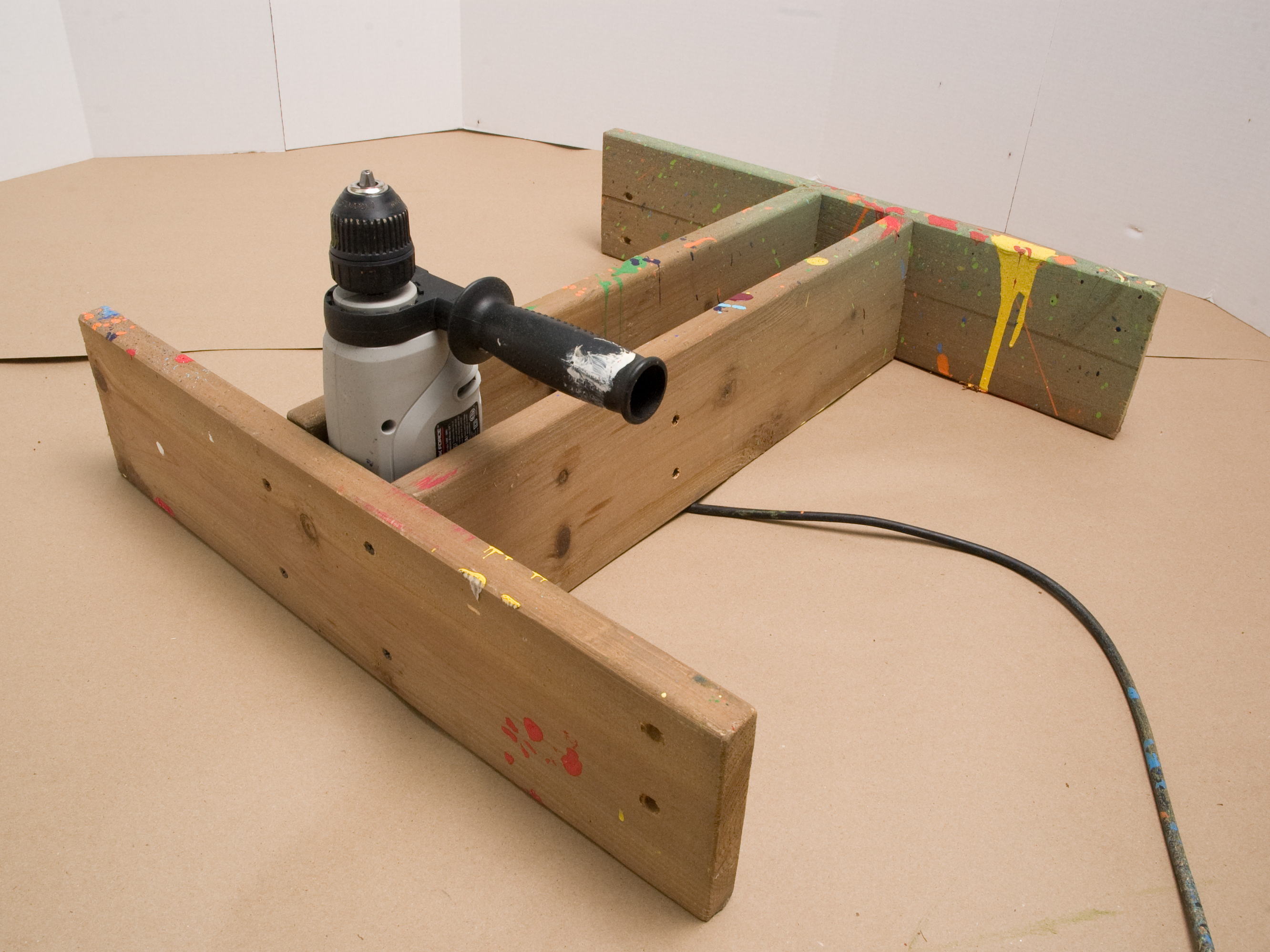

So we tried it, and after burning out the motor from a box fan, we realized that a corded power drill would work better. Corded power drills are cheaper than battery-operated drills, and they typically have greater torque. Many even have a speed knob on the trigger, offering more control.

WARNING

- Adult supervision required for younger children.

- Watch your knees! And don’t lean over the device so far that you fall onto it.

- Stop the device immediately if it ever tips over. We stake ours to the ground.

- Keep electrical plugs out of the area where the paint is; don’t mix electricity and liquids.

- To minimize risk of electrocution, plug the device into a ground-fault circuit interrupter outlet. These are often labeled GFI or GFCI, with test and reset buttons on them.