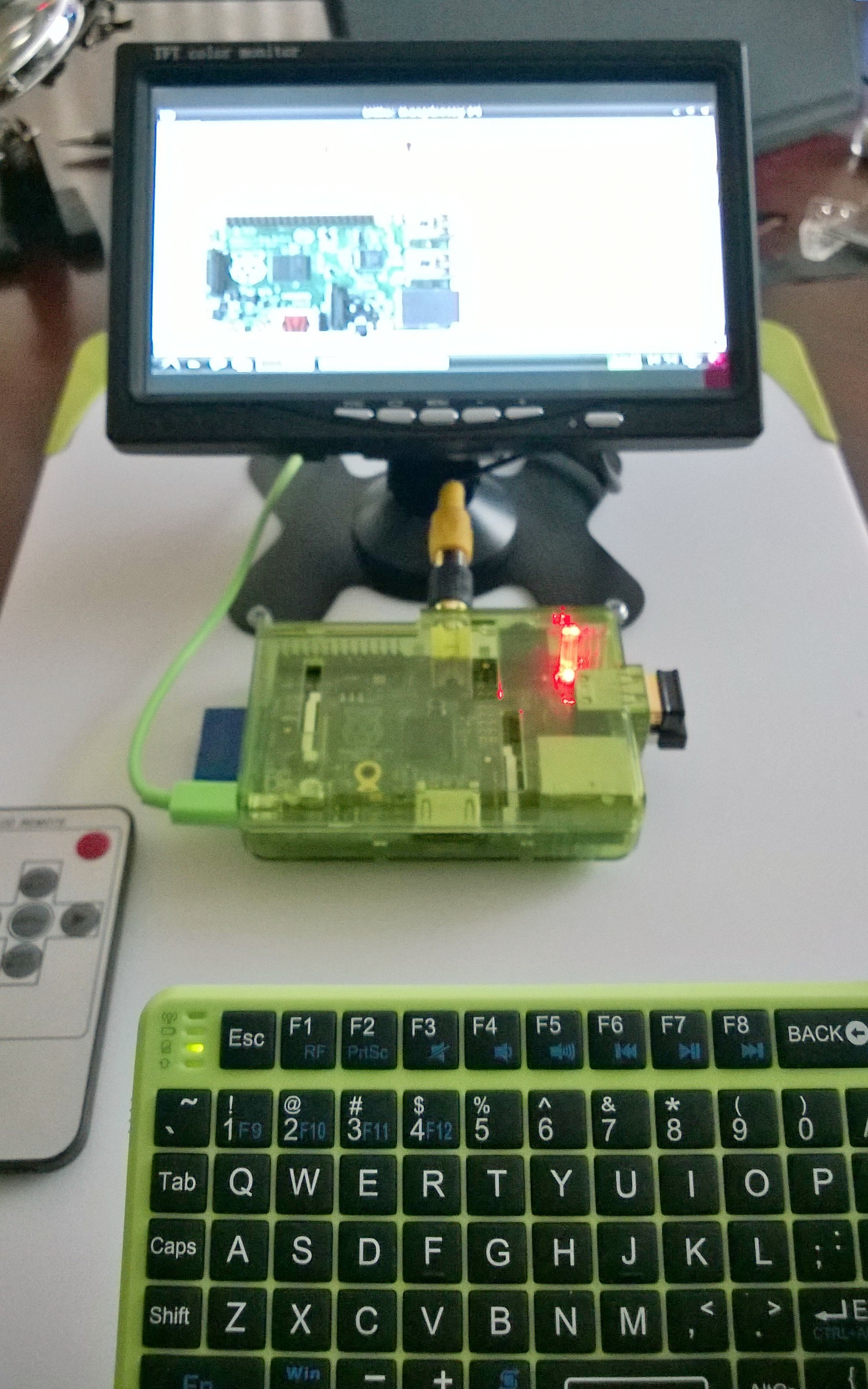

And it’s done! With all the Pi accessories hooked up, and the wireless access point configured, I’m able to access the Raspberry Pi website via the browser. The fun part is that I am using a miniature wireless integrated keyboard and mouse . Added to this, my monitor also has a wireless remote with which I can turn it on or off.

As you can see, I can swivel the monitor and work with my Pi using the wireless keyboard. When mounted up on the wall, the Pi is going to be equally accessible and operates autonomously. And all that wiring is off my desk. The only two wires leading out from behind the cutting board would be the power cables for the monitor and the Pi.

The final and most difficult step is to convince the wife to allow me to wall mount this project. Well that’s a whole another story!