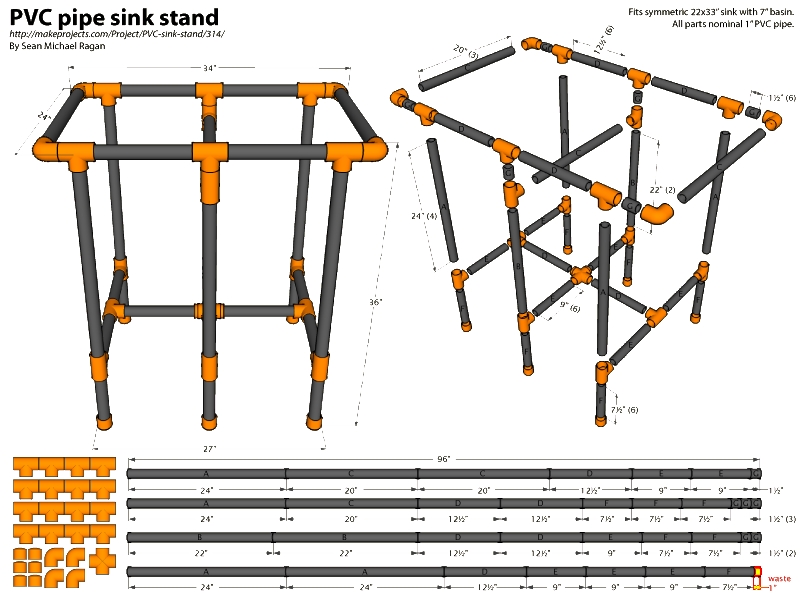

All the kitchen chemistry at my last place left the sink in no condition for human habitation, so I replaced it when I moved out, and took the old one with me. After some diligent scrubbing, it was ready to serve as a utility sink in my garage/workshop, hooked up to the washer/drier connection there. All I lacked was a stand, and since I’d recently scored a bunch of these cool orange-colored Blazemaster PVC fittings at the Habitat for Humanity ReStore for a song, I decided to make it out of PVC.

I used gray schedule 80 pipe solely for looks. If you can’t find or don’t want to spring for fancy PVC pipe and/or fittings, you can always try staining your own.