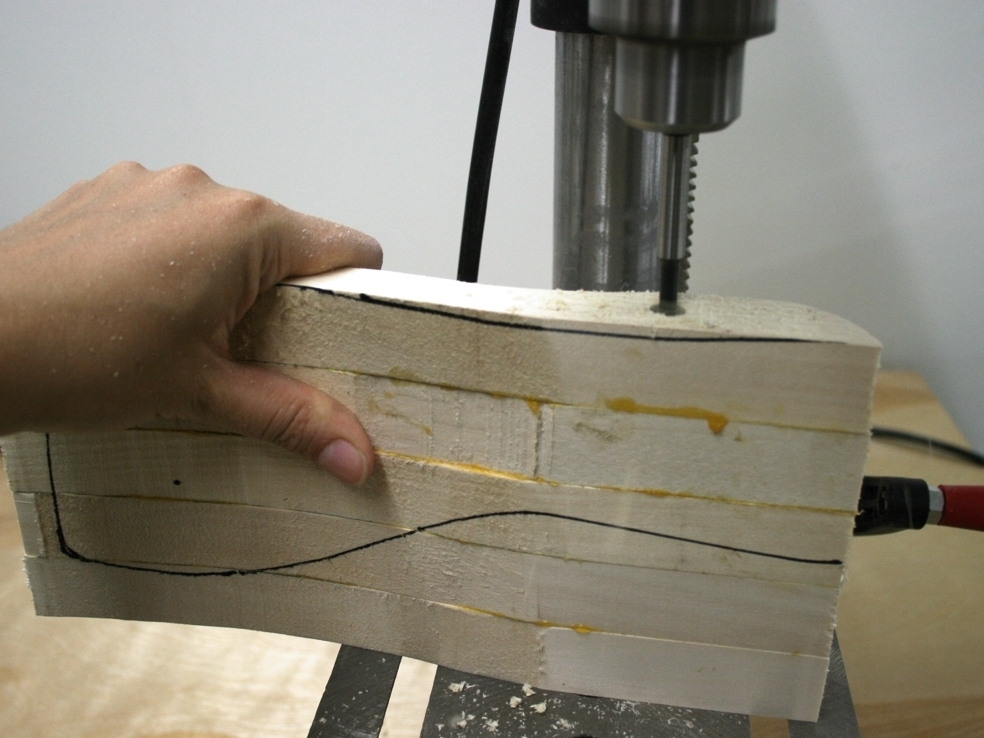

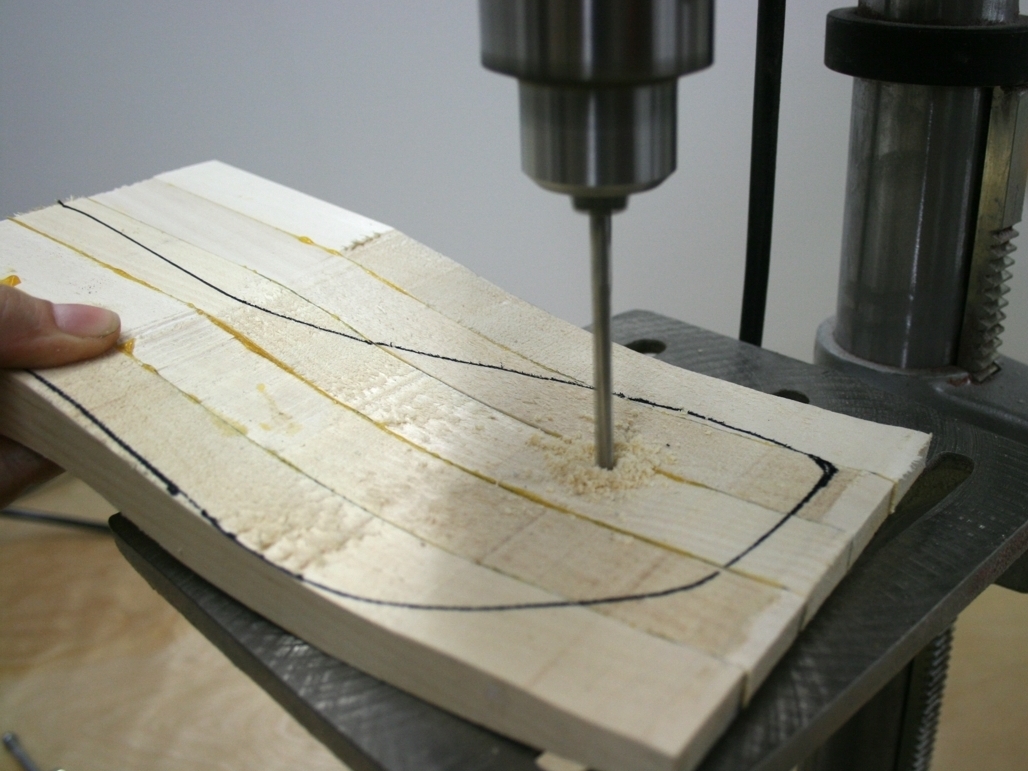

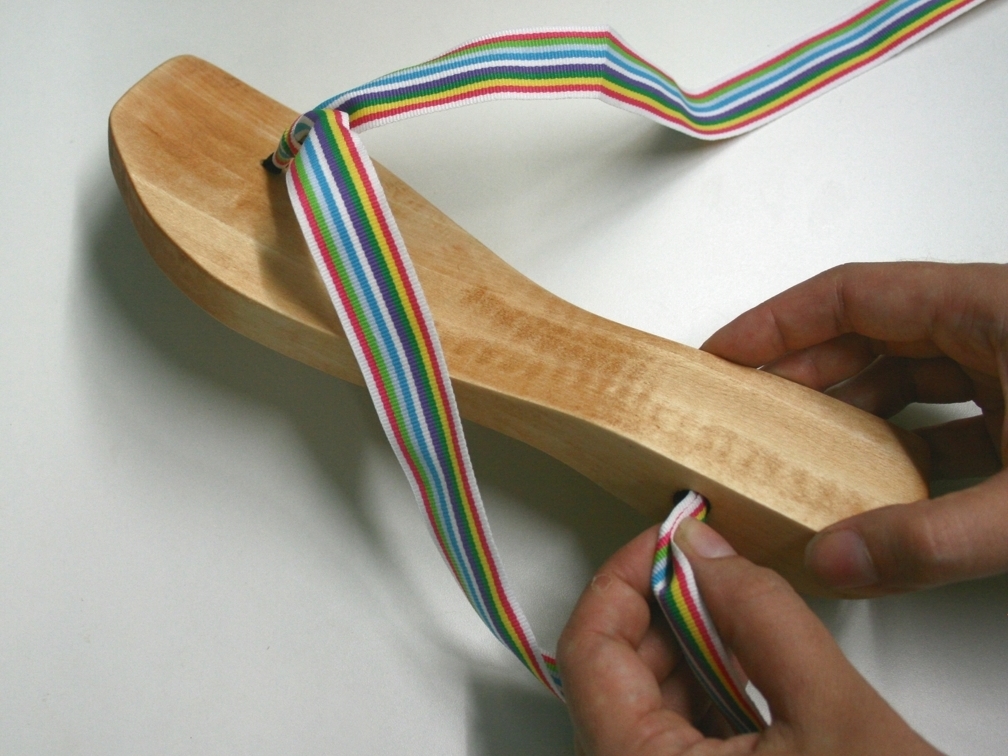

Nearly as long as humankind has roamed the earth, people have been wearing shoes. Ancient Egyptians, Indians, and East Asians began sporting wooden sandals thousands of years ago. Thankfully, inexpensive power tools have sped up the tedious process of carving ergonomic shoes from slabs of wood. Add a few interchangeable ribbon ties, and you’ve got a modern twist to the ancient thong-style sandal. With a variety of wood finishes, footbed shapes, and ribbon styles, along with myriad ways to lace and tie the shoes, the design options for these sandals are nearly limitless. So take a cue from history and fashion yourself a custom pair of wooden kicks.