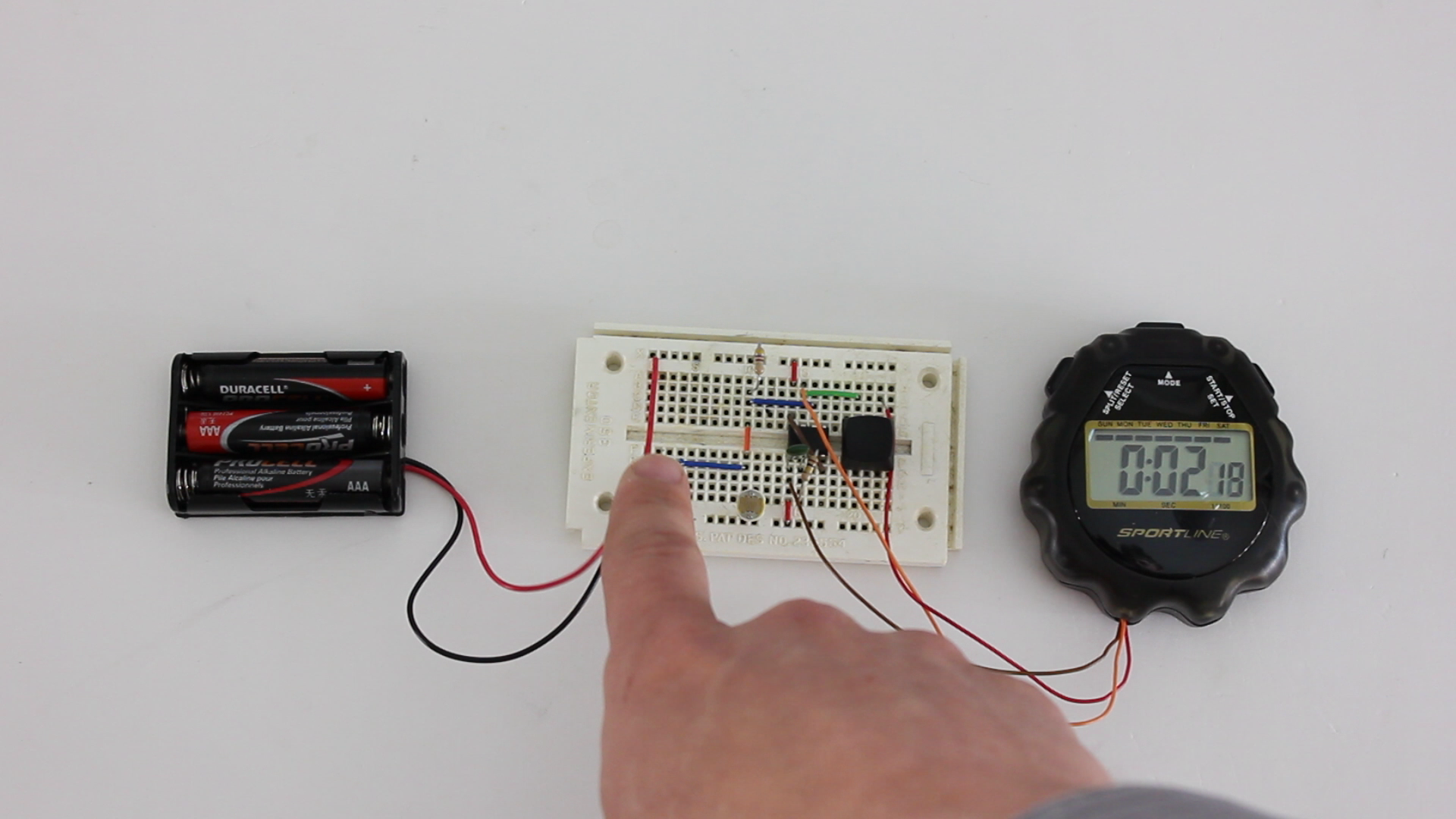

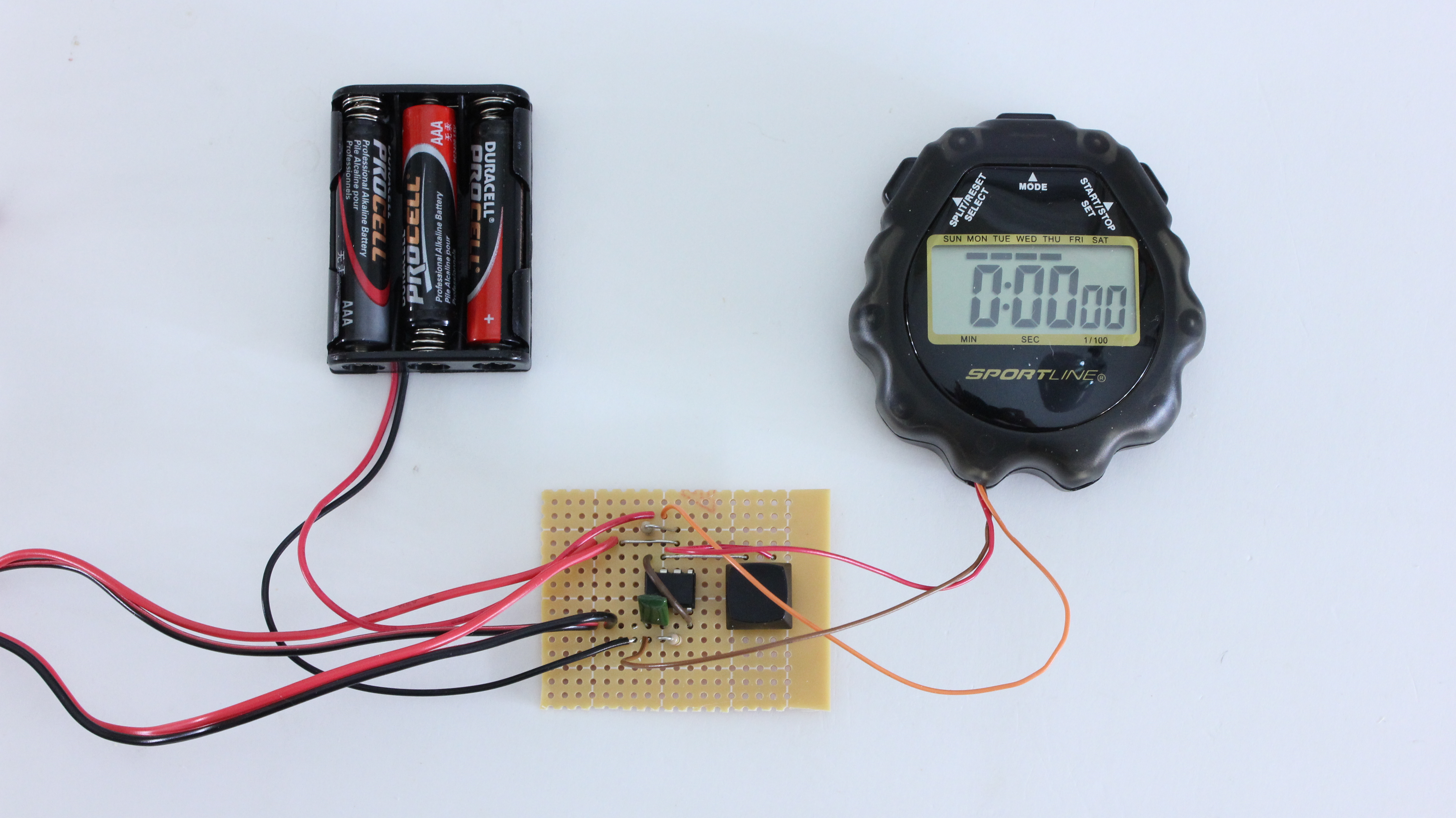

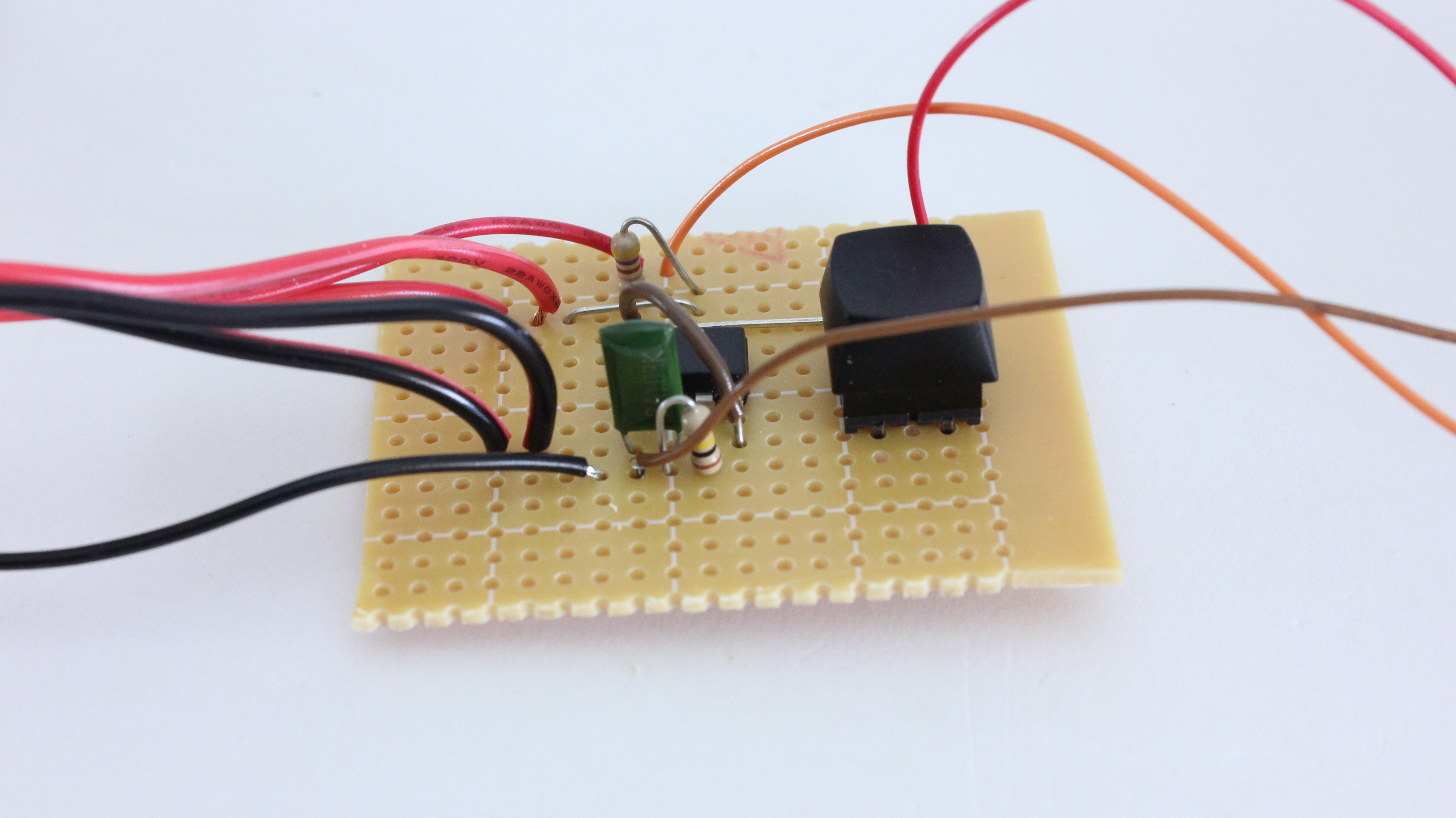

Racing toy cars, like Pinewood Derby or CO2 dragsters, is a lot of fun. But if you want to compare the results of multiple races, you need be able to accurately record the finishing times of each one. To do this, I designed a timer circuit that will automatically record the finishing times.

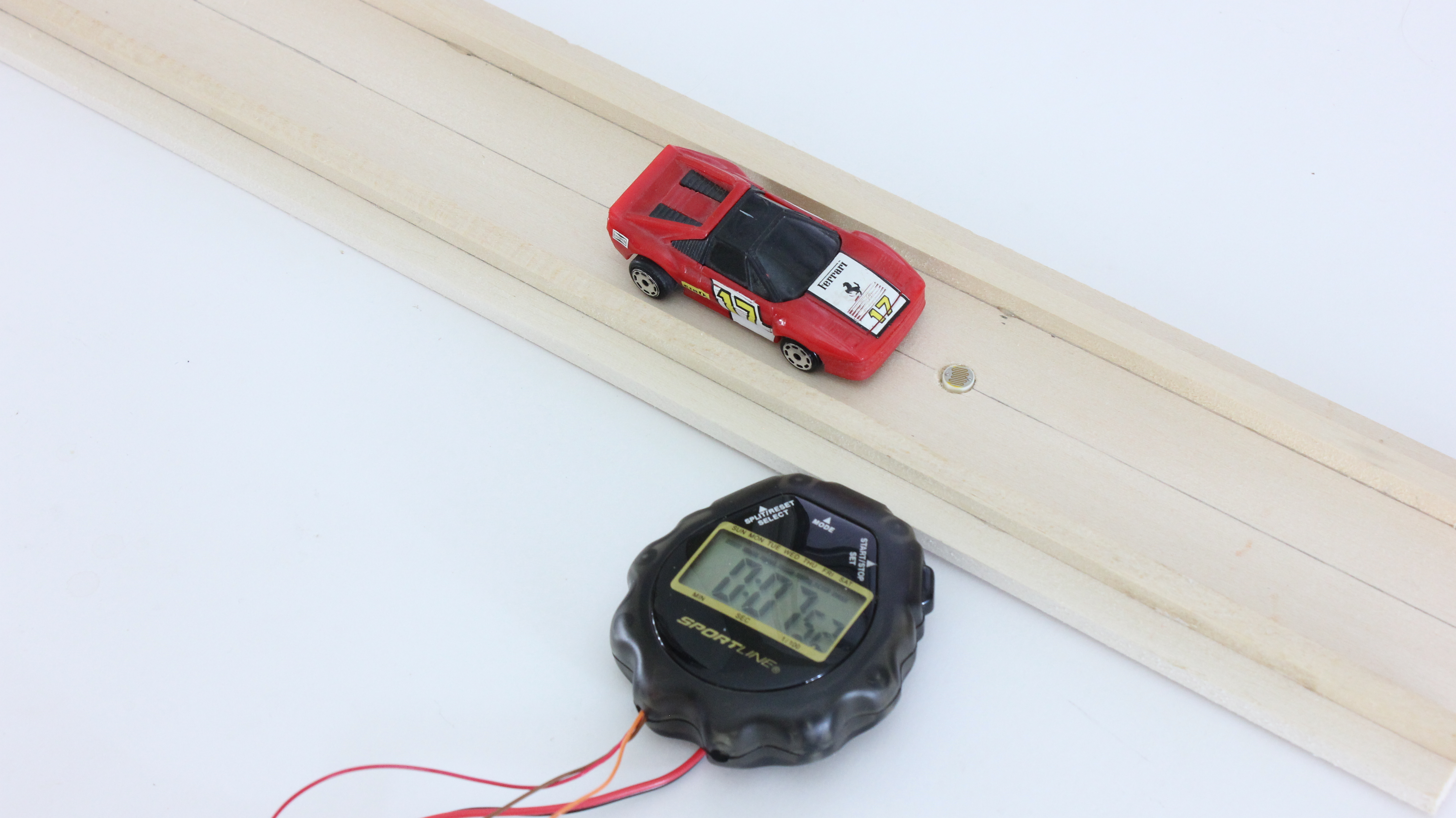

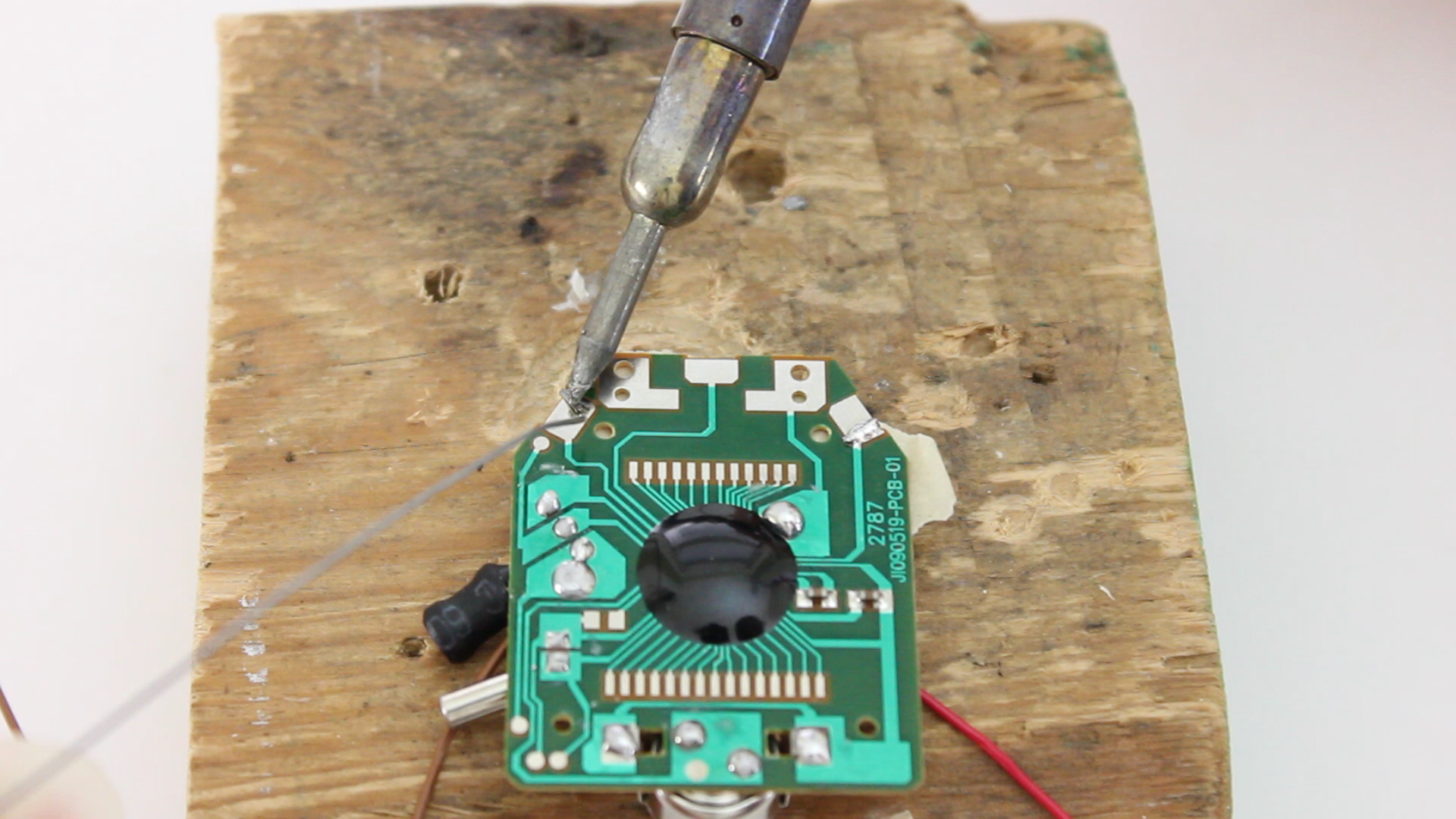

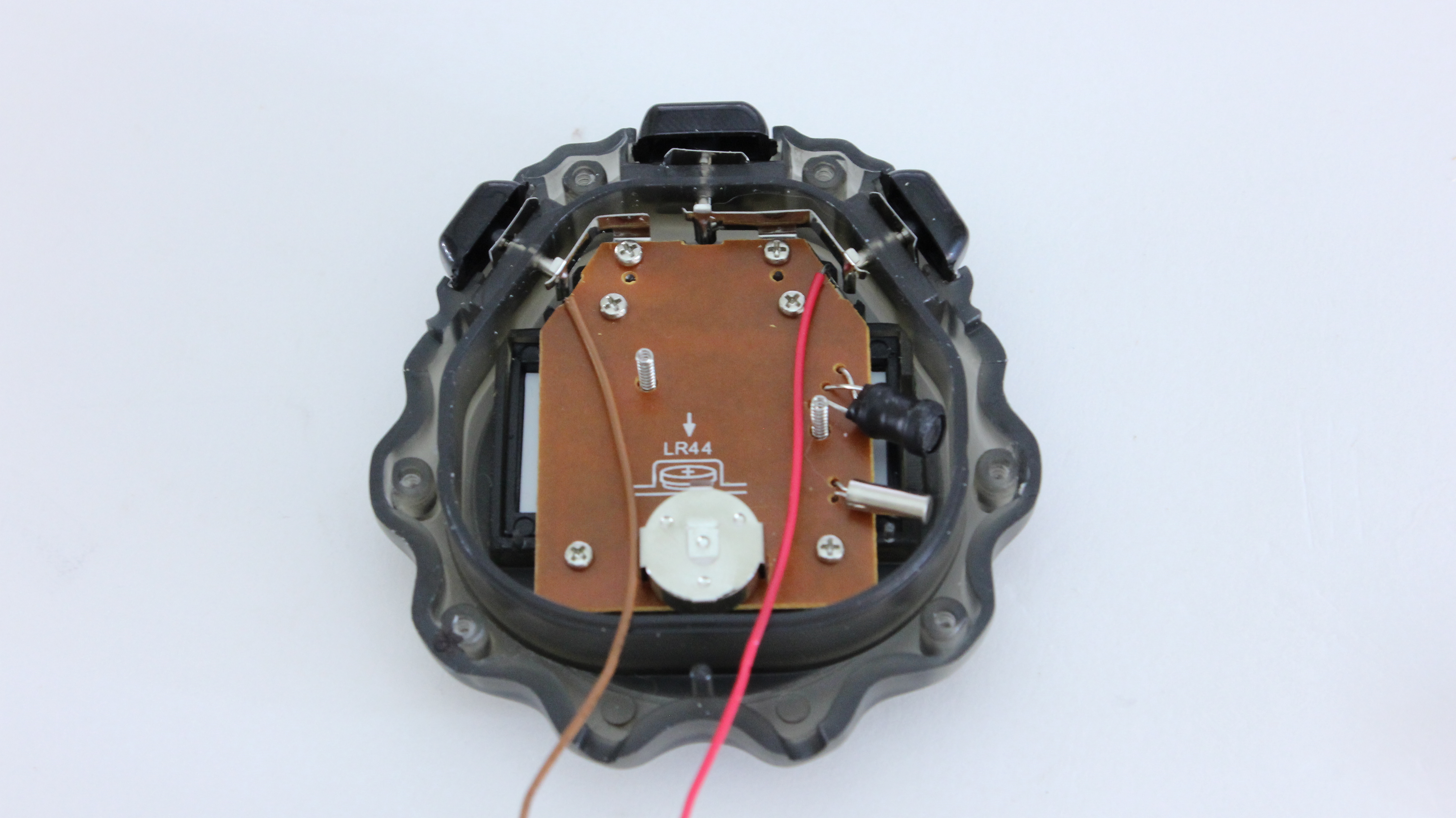

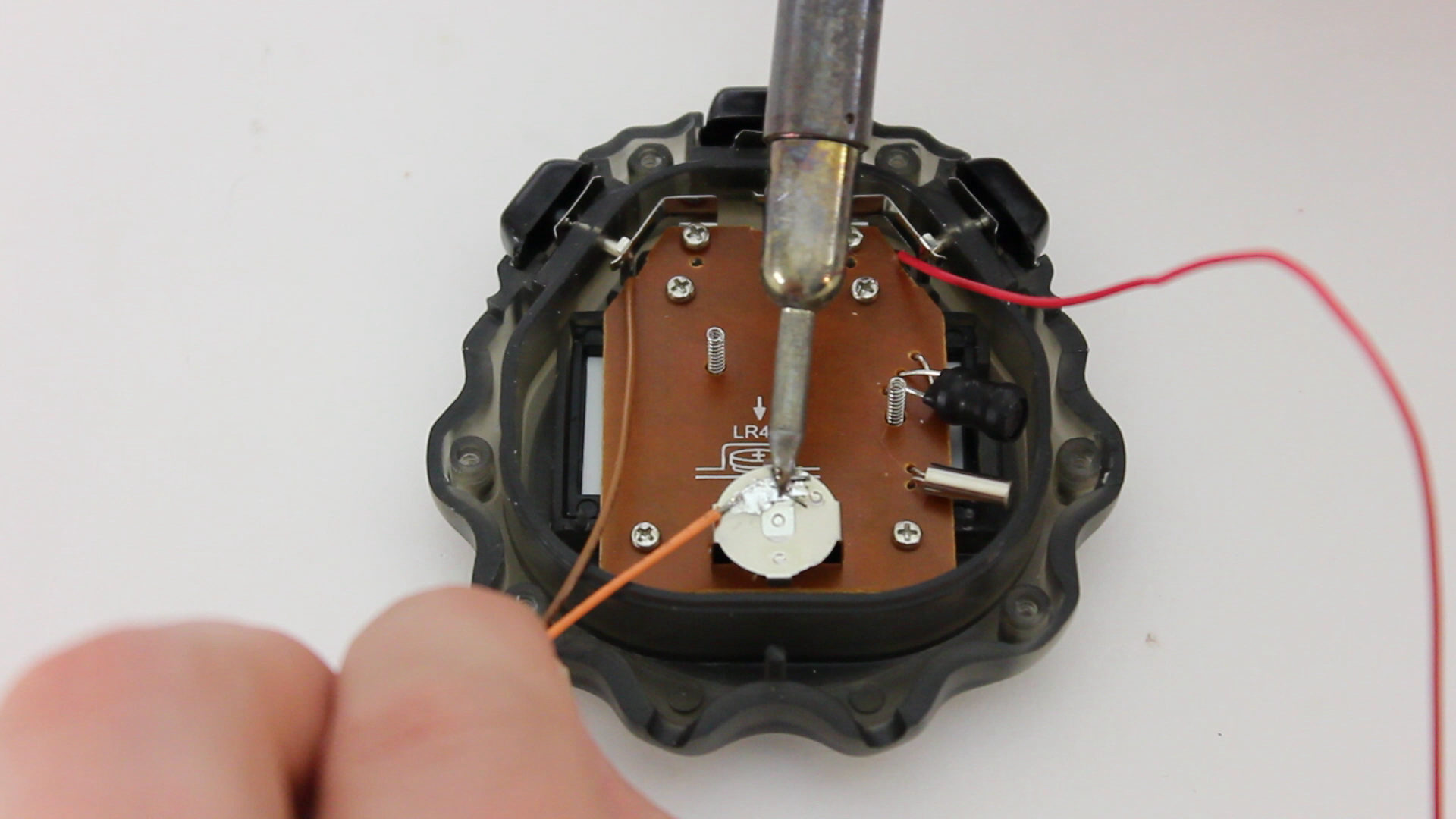

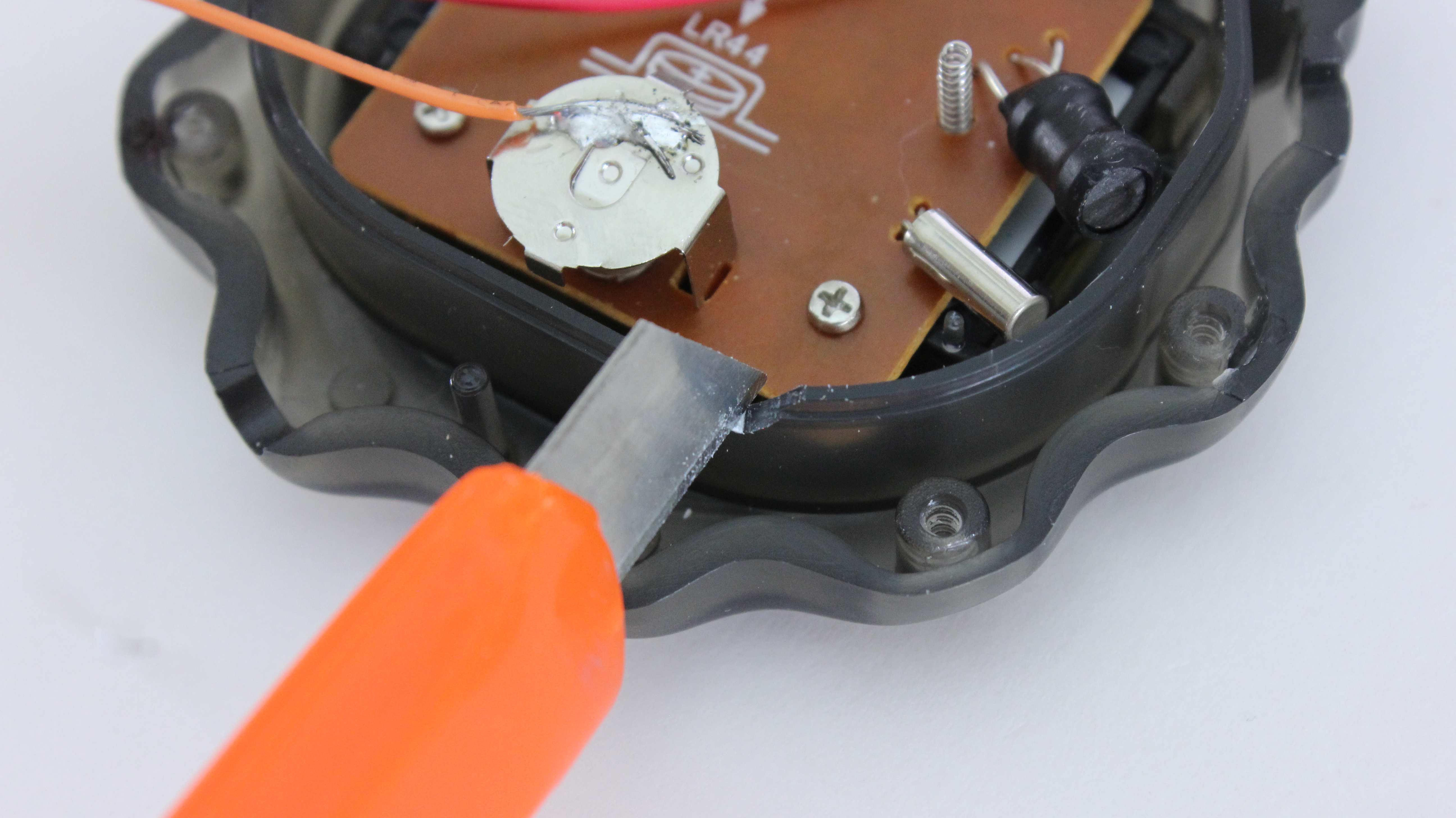

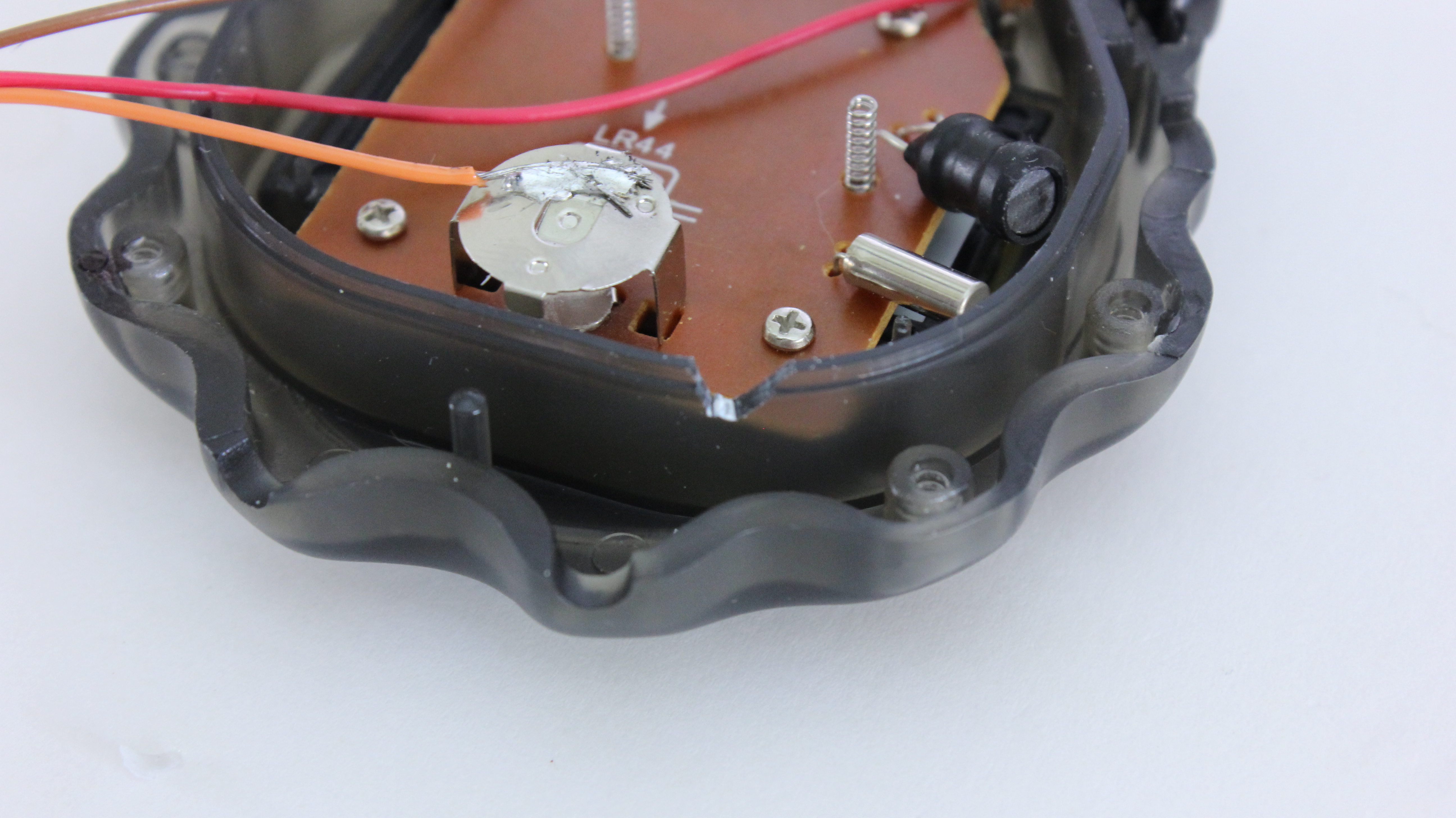

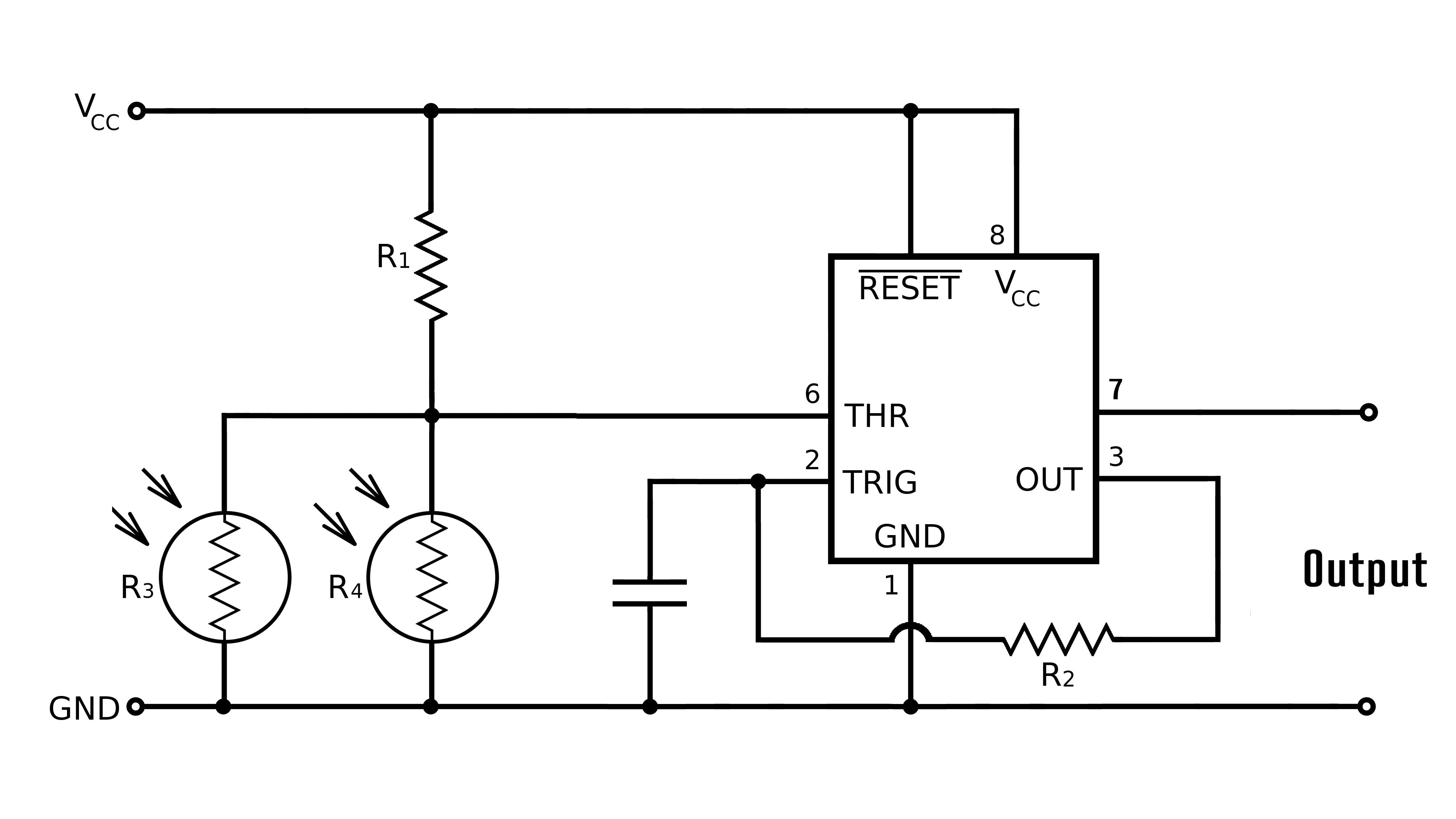

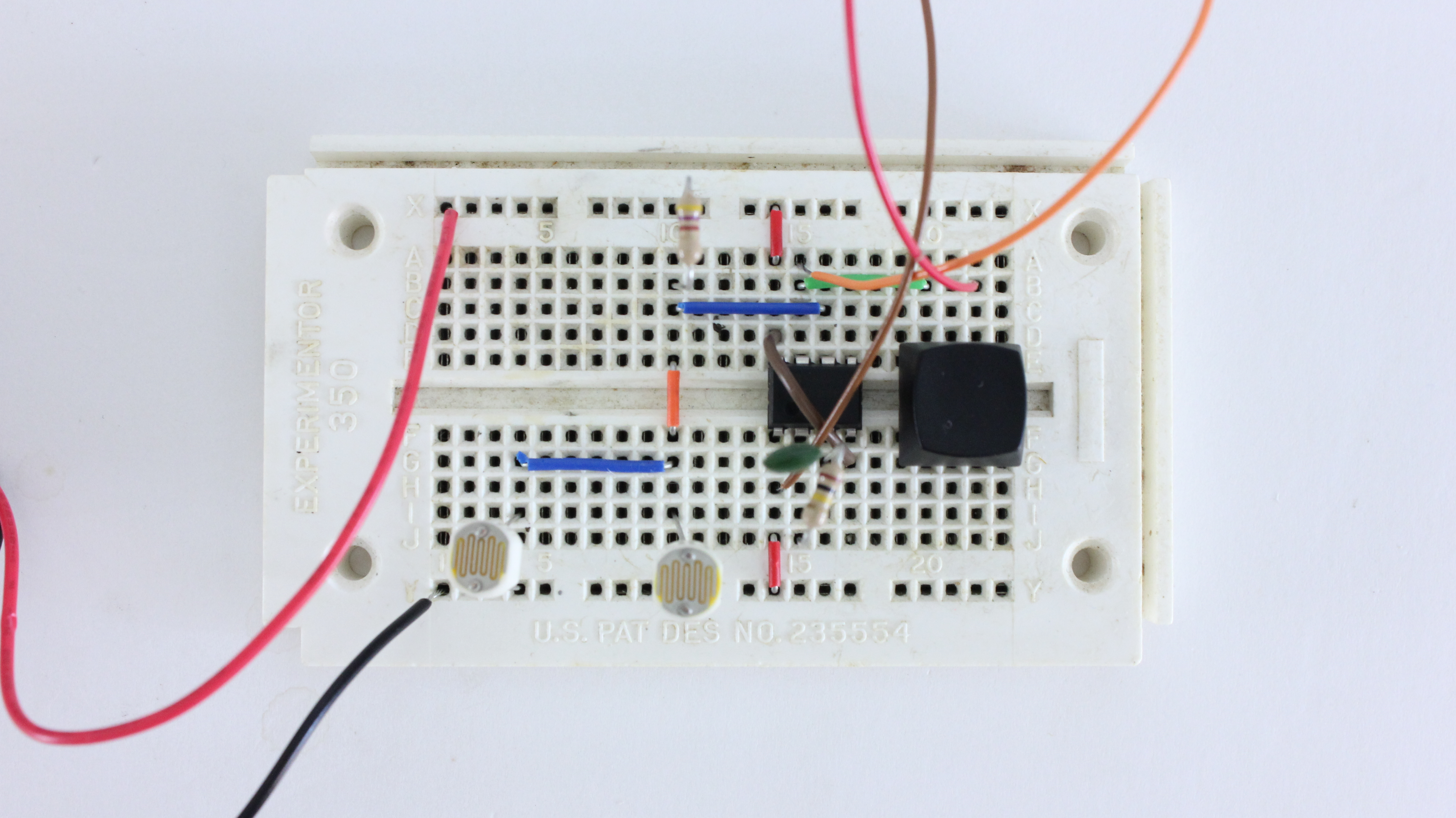

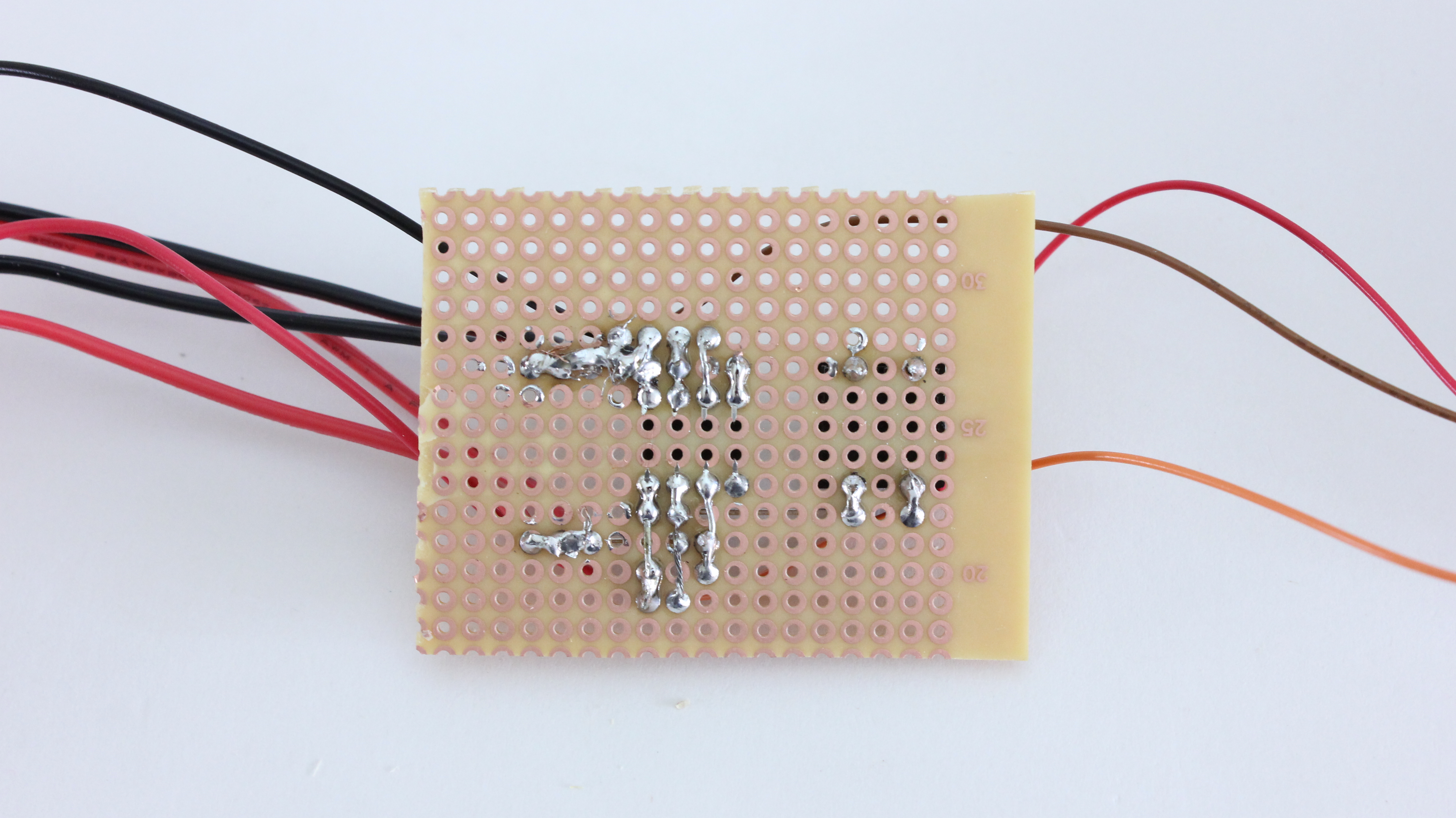

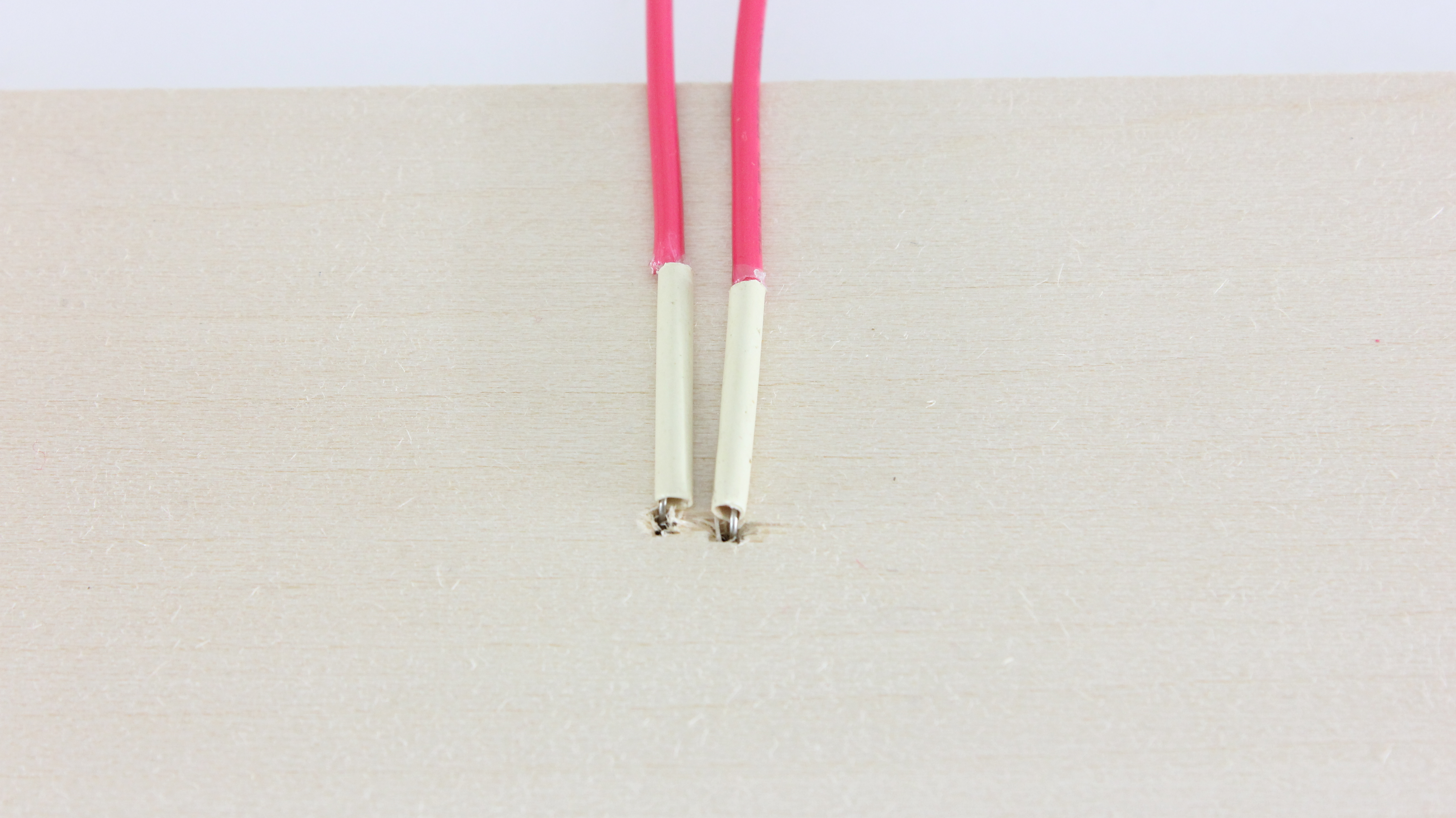

Two light sensors are mounted on a track. The first one is positioned just in front of the starting line. The second is located at the finish line. When the car crosses the first sensor, it starts the timer. Then when the car crosses the second sensor, it stops the timer. This lets you automatically record the finishing time of each car.

The system that I built is tailored to toy car races but it can easily be adapted for other kinds of races.