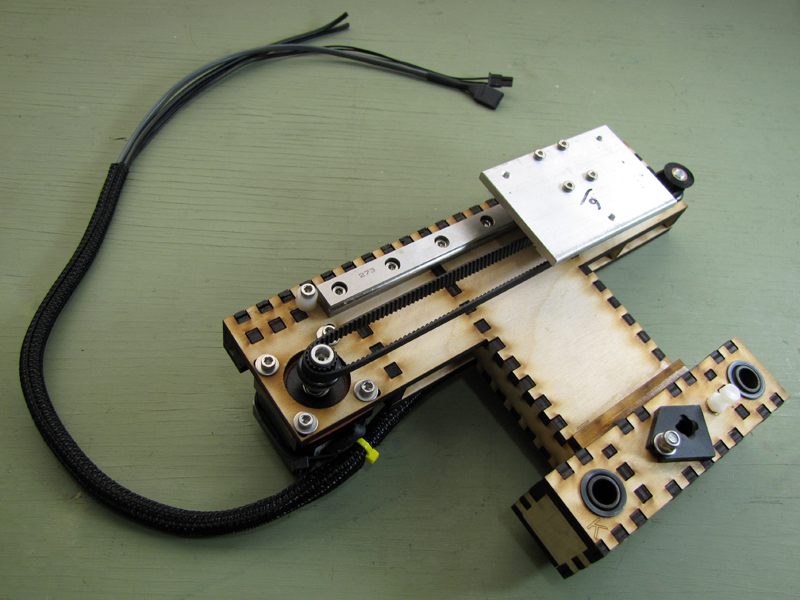

This is the step in which the timing belt is actually put under tension. If it is too tight, or too loose, its length will have to be adjusted following the general procedure in the previous step.

Noting the correct orientation of the white plastic belt tensioner, slip the belt over the fixed drive pulley on the motor shaft.

Slip the belt into the groove of the loose idler pulley, then stretch the belt to slip the idler pulley over the idler shaft. If the belt tension is correct, it will take a bit of force to do this.

The idler pulley gear and the drive pulley gear should be at the same height. If they are not, the belt will tend to ride up and slip off as it is moved. To re-align, simply loosen the drive gear set screw on the motor pulley and move it up to match the height of the idle gear, and then carefully re-tighten the set screw.

With the belt in place, adjust the position of the belt tensioner until it is centered over the linear bearing. Observe the belt as you do so. The rule of thumb for belt tension is: “when you slide the pulley back and forth, the belt should not bulge as it moves around the pulleys.”

If the belt is too tight or too loose, remove and shorten or lengthen it, as necessary, following the procedure in the preceding step.