Some days the coolest “toy” in my garage/shop is my son Reed’s zoomy Lotus Elise sports car. On a recent visit, he was frustrated that the original battery cover wouldn’t quite fit over his new, larger battery. It was the perfect opportunity to try out my new strip heater by making a new cover.

Strip heaters are great for making accurate bends in thermoplastic parts. I picked up a pre-wired heater element made by BriskHeat (see MAKE Volume 36, page 149 for a review). It comes with directions for mounting the element in a plywood channel, lined with heatproof fiberglass and foil. I’d recommend using adhesive-backed foil tape instead; it adheres to the plywood and also traps the fiberglass’ fraying edges.

I designed a simple two-part cover and using a white china marker, laid out the parts on a sheet of 0.09″ textured black ABS. I then drilled ½” holes to make radiused inside corners for stress relief. I scored the cuts with a sharp utility knife and bent them to snap apart. To de-burr the sharp edges, I scraped them with the knife. The strip heater softens the plastic evenly and gently for smooth, tight bends. Be sure to plan your sequence of bends so that you always have a flat surface to heat.

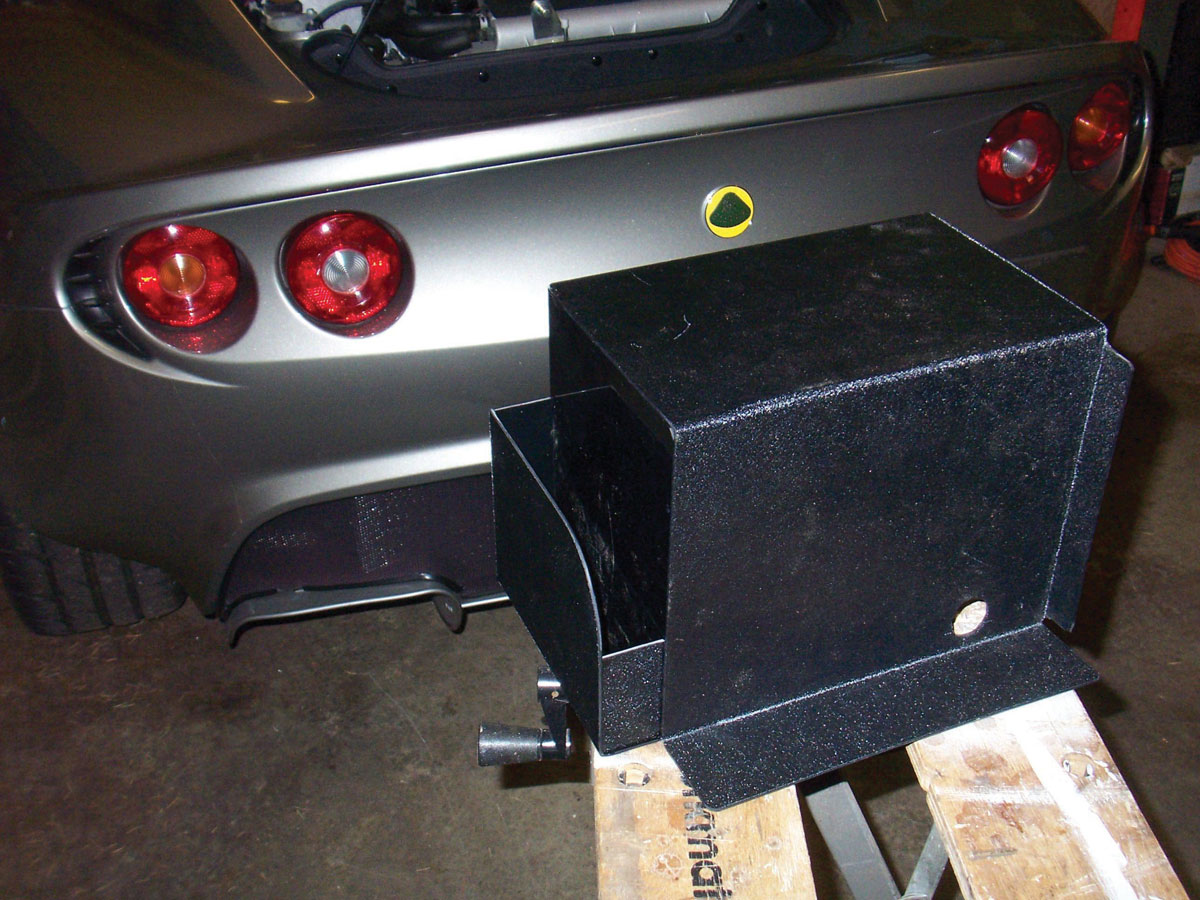

I bonded the parts together with MEK solvent. A U-shaped bend in the back creates a storage compartment, together with a few side pieces. Self-adhesive Velcro spots on the bottom of the S-shaped top flanges hold the removable cover in place inside the Elise’s tiny trunk.