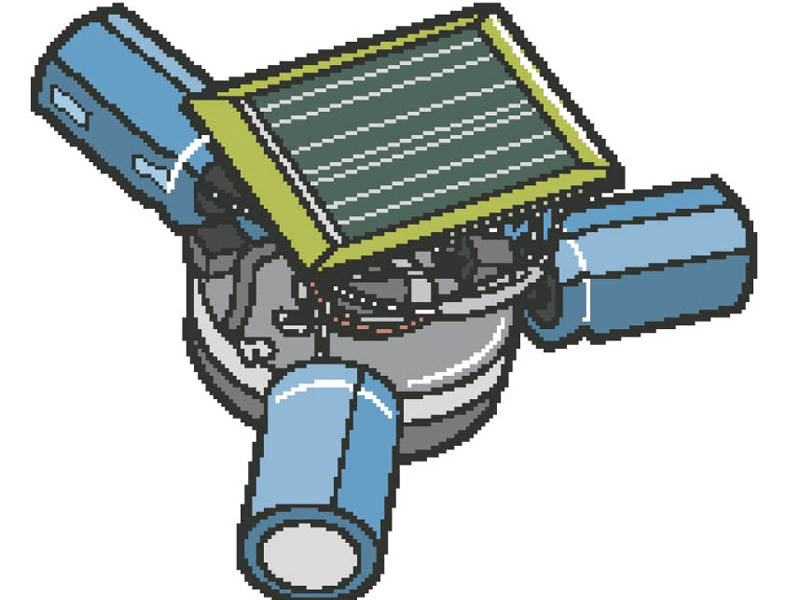

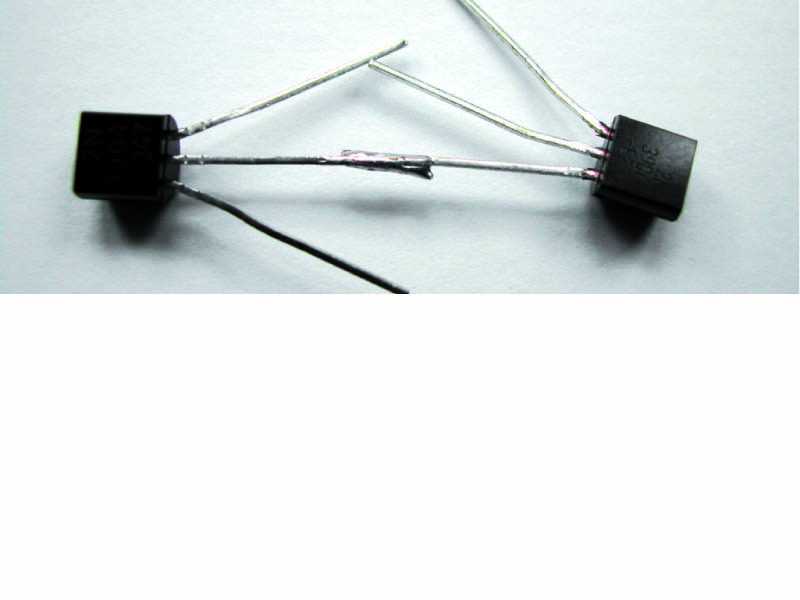

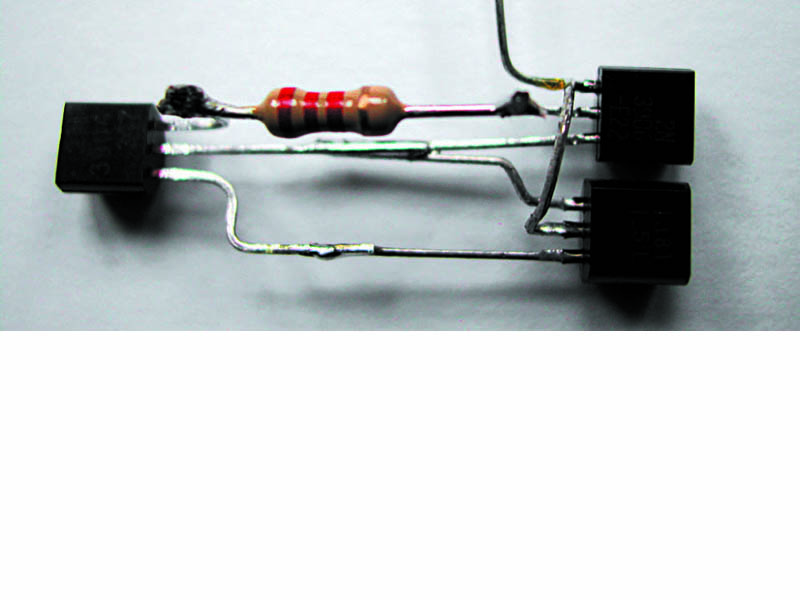

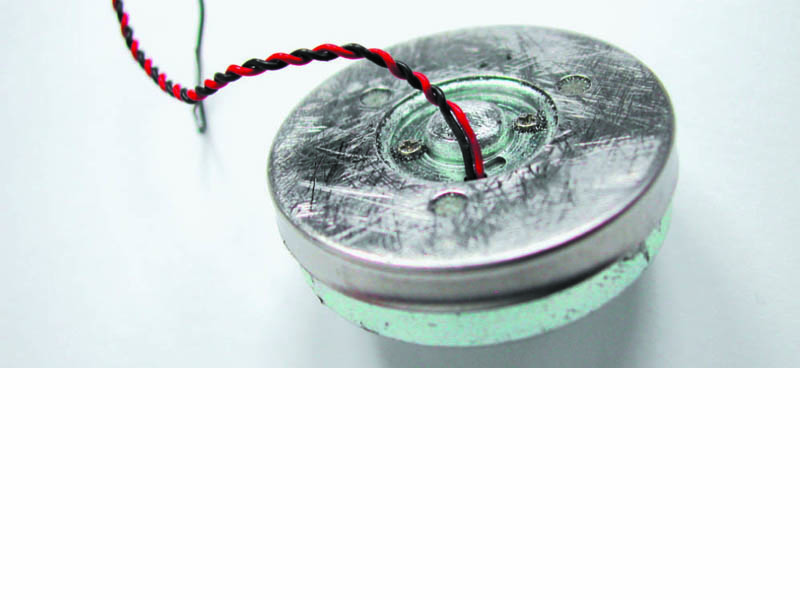

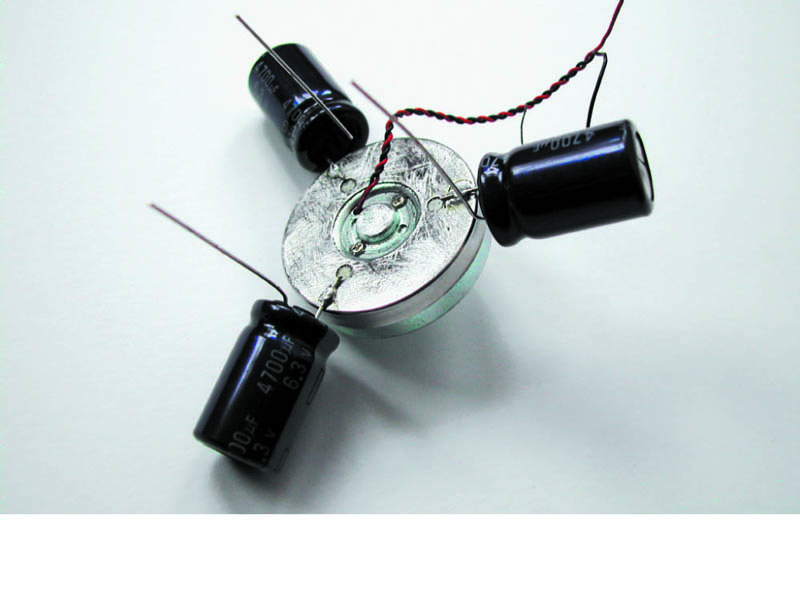

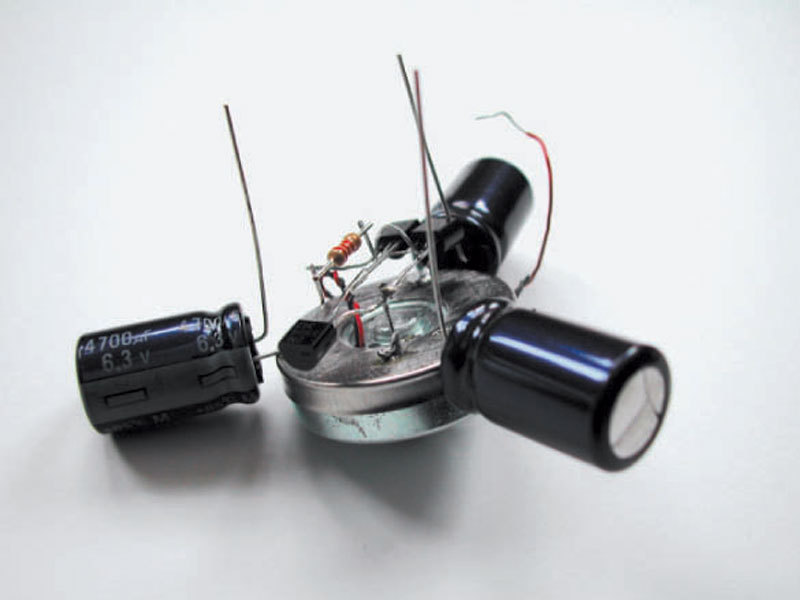

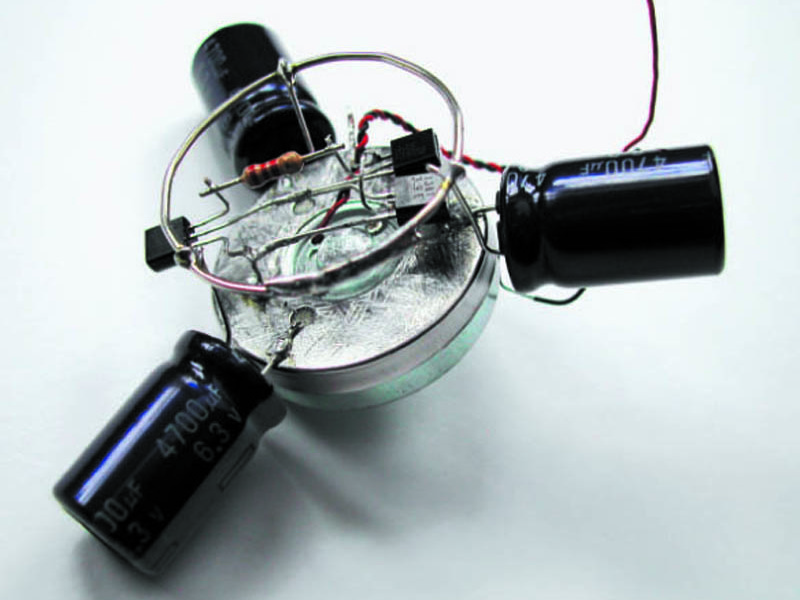

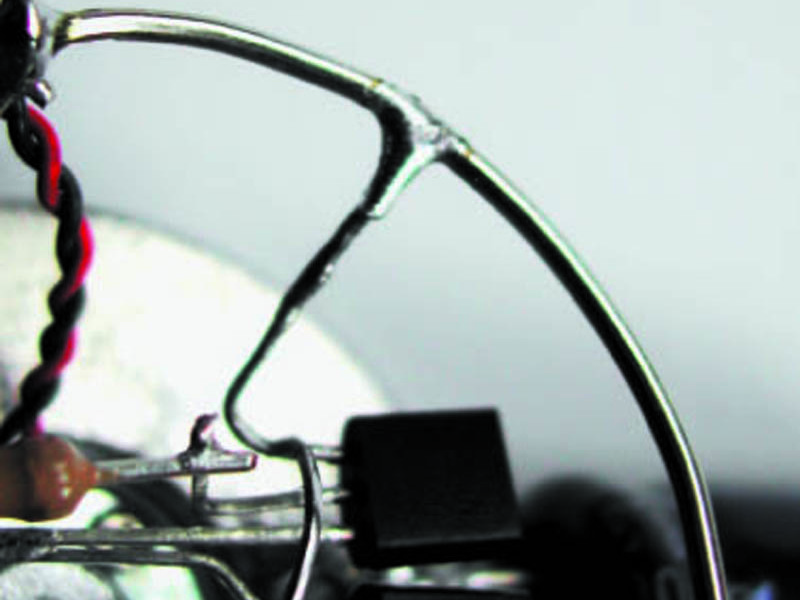

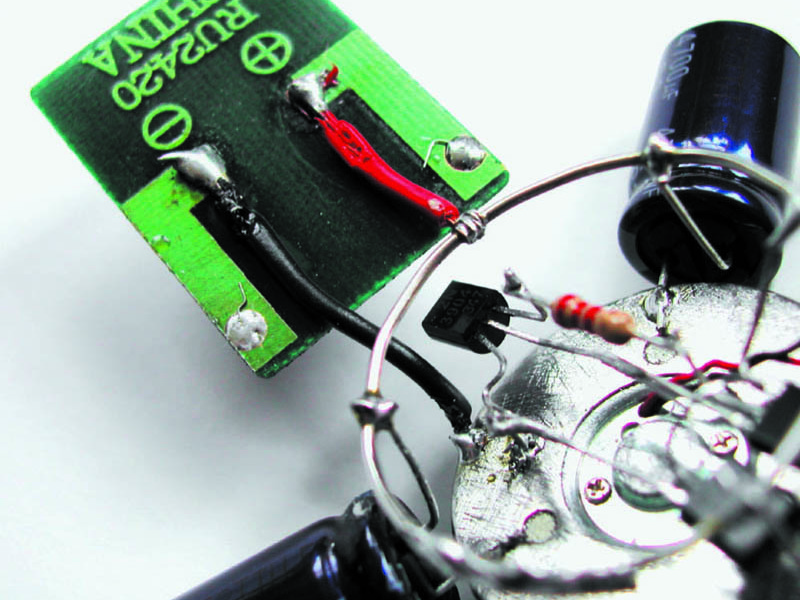

A Symet is a simple BEAM spinner that incorporates a common BEAM solar power management circuit called a voltage-tiggered (Type 1) Solar Engine. A “Trimet” is a Symet with three symmetrically-balanced components. A Trimet is basically comprised of the MSE, a DC motor scavenged from a cassette player, a solar cell, and three capacitors that store the energy from the cell (and also act as the main structure of the “bot”).

Projects from Make: Magazine

Trimet, Solar BEAM Top

A little spinning top that looks like a satellite in orbit.