Assembly continues by creating the circuit for the XBee. Set aside your XBee module for now; we’ll use it later.

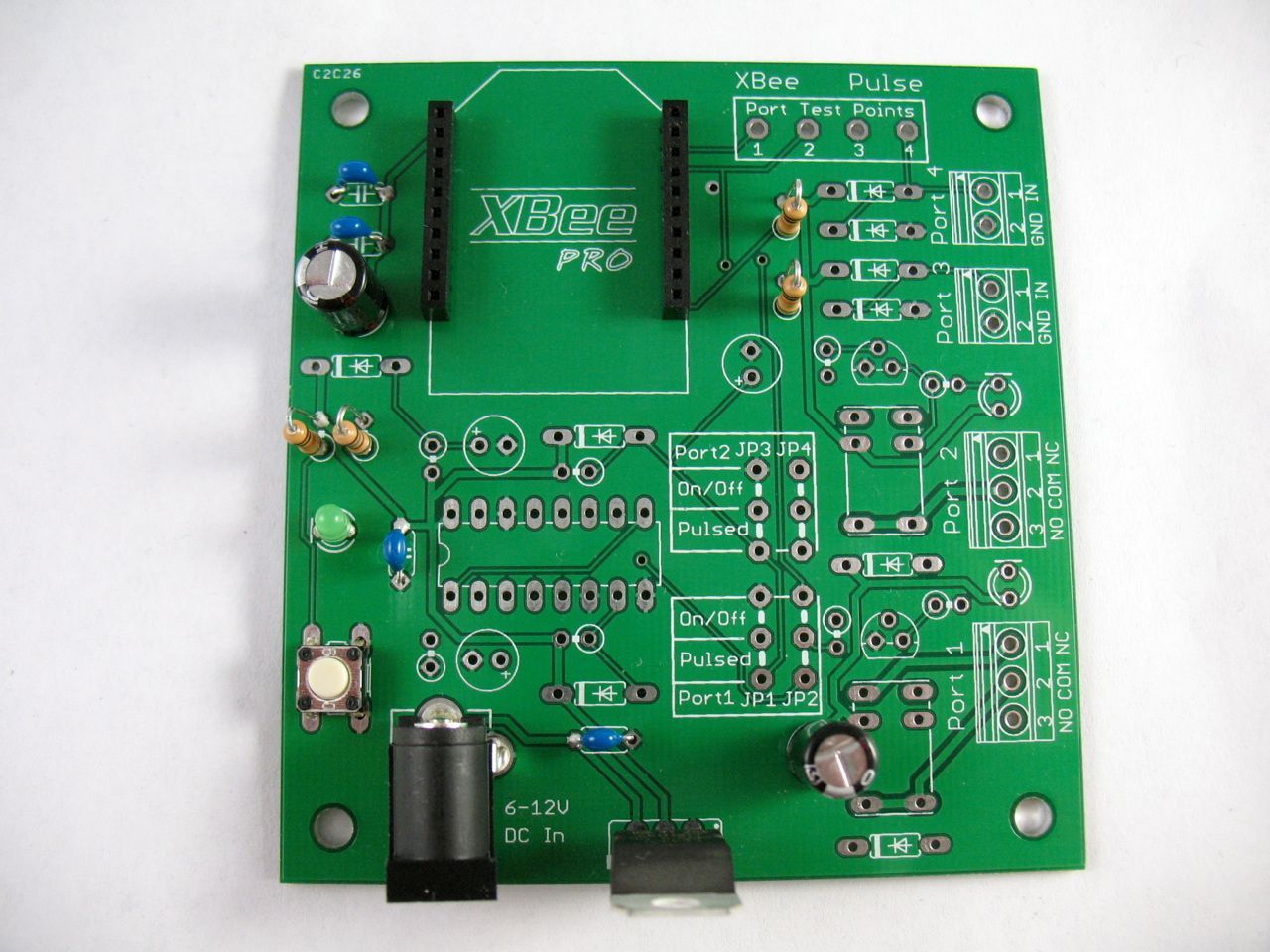

Solder the two sets of female headers for the XBee into place as shown. These will allow your radio to be removed for reprogramming if desired.

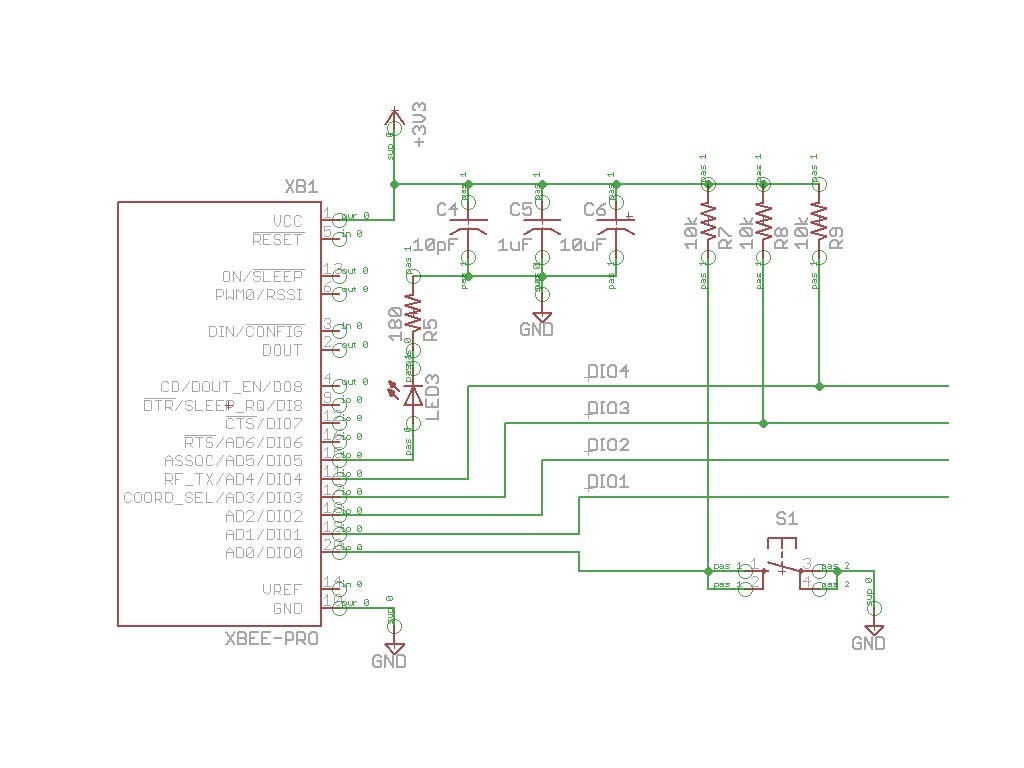

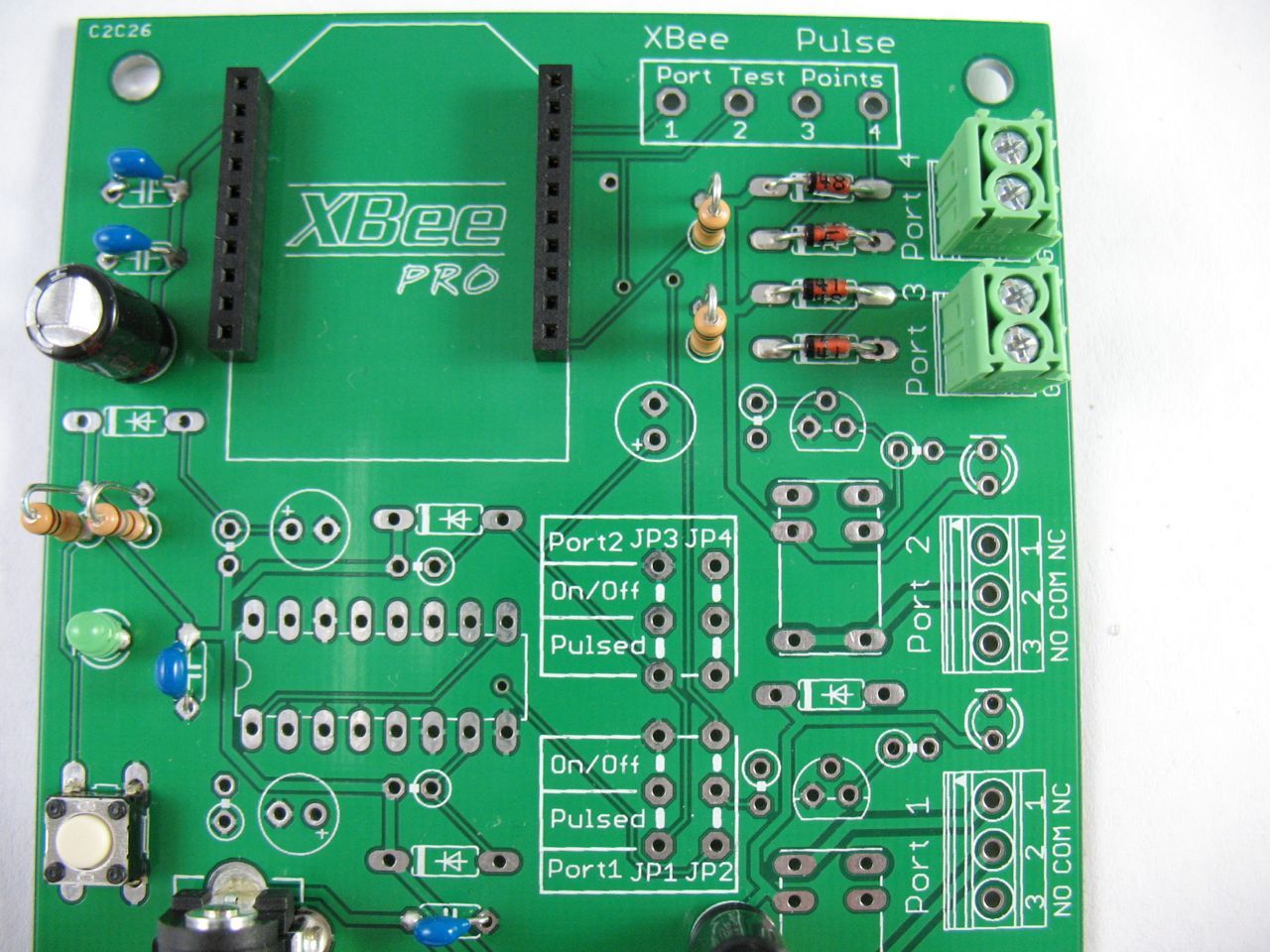

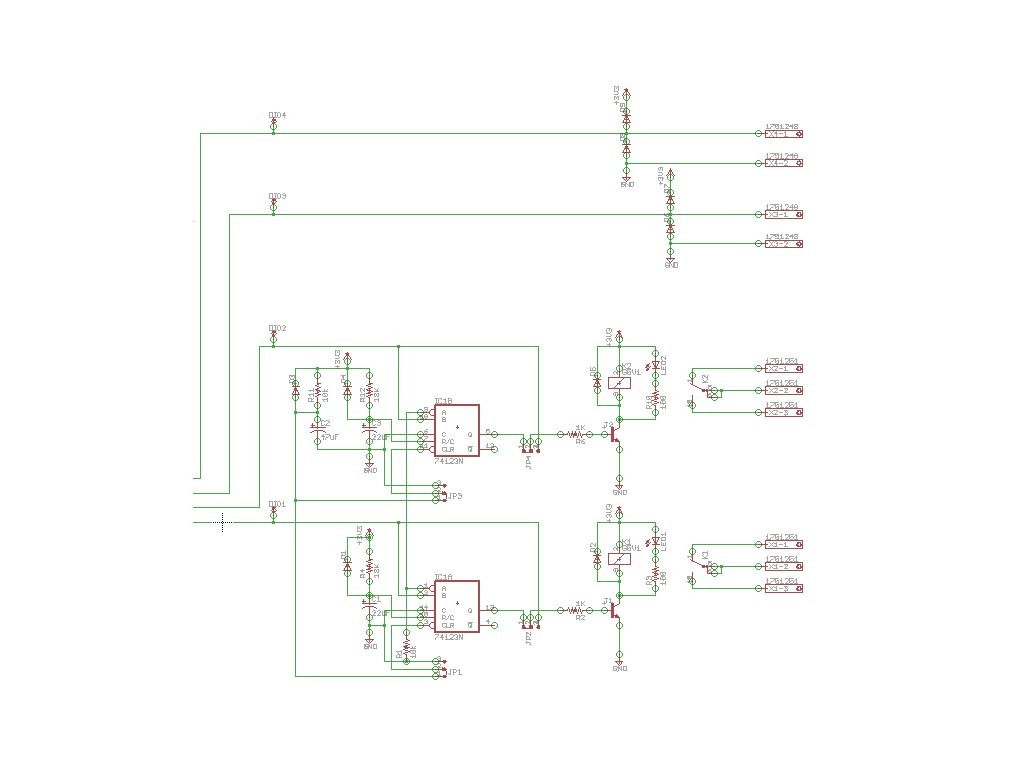

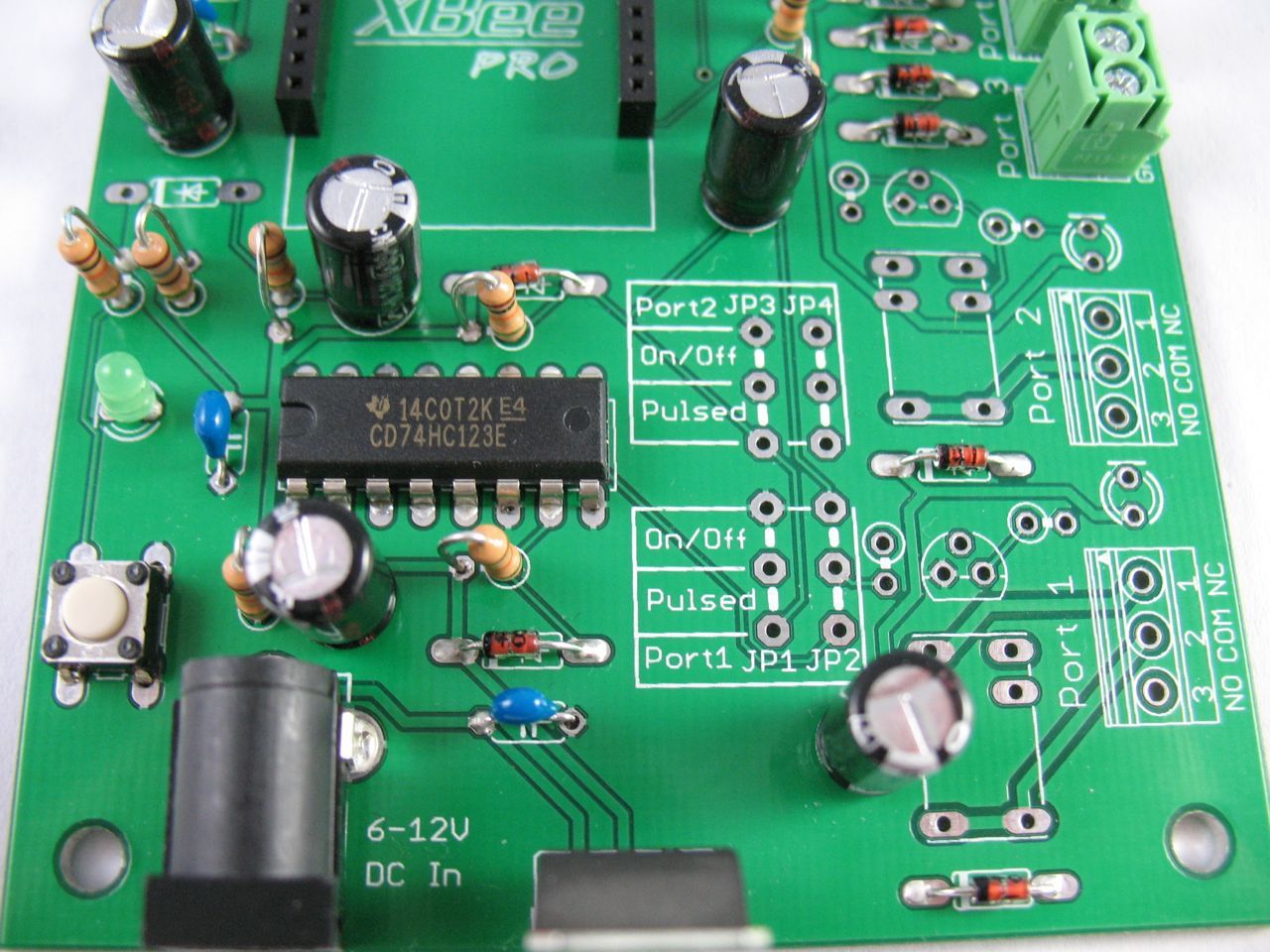

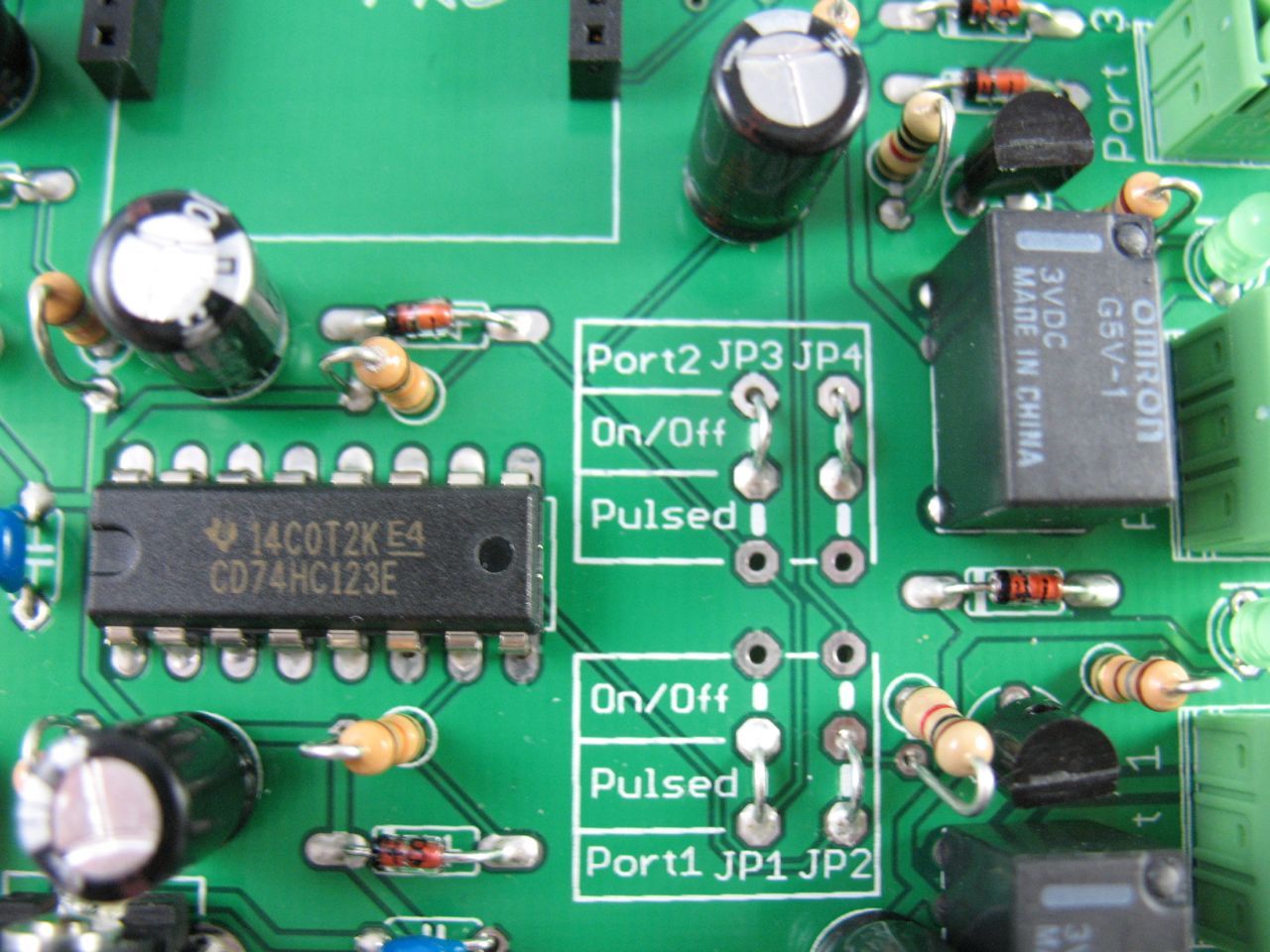

Next solder three 10K-ohm resistors to R7, R8 and R9. The resistor colors are brown, black, orange, gold. Bend one leg all the way over so the resistors can be soldered in upright as shown. Trim the legs.

Solder a 180-ohm (NOT 180K!) to R5 as above. The resistor colors are brown, grey, brown, gold.

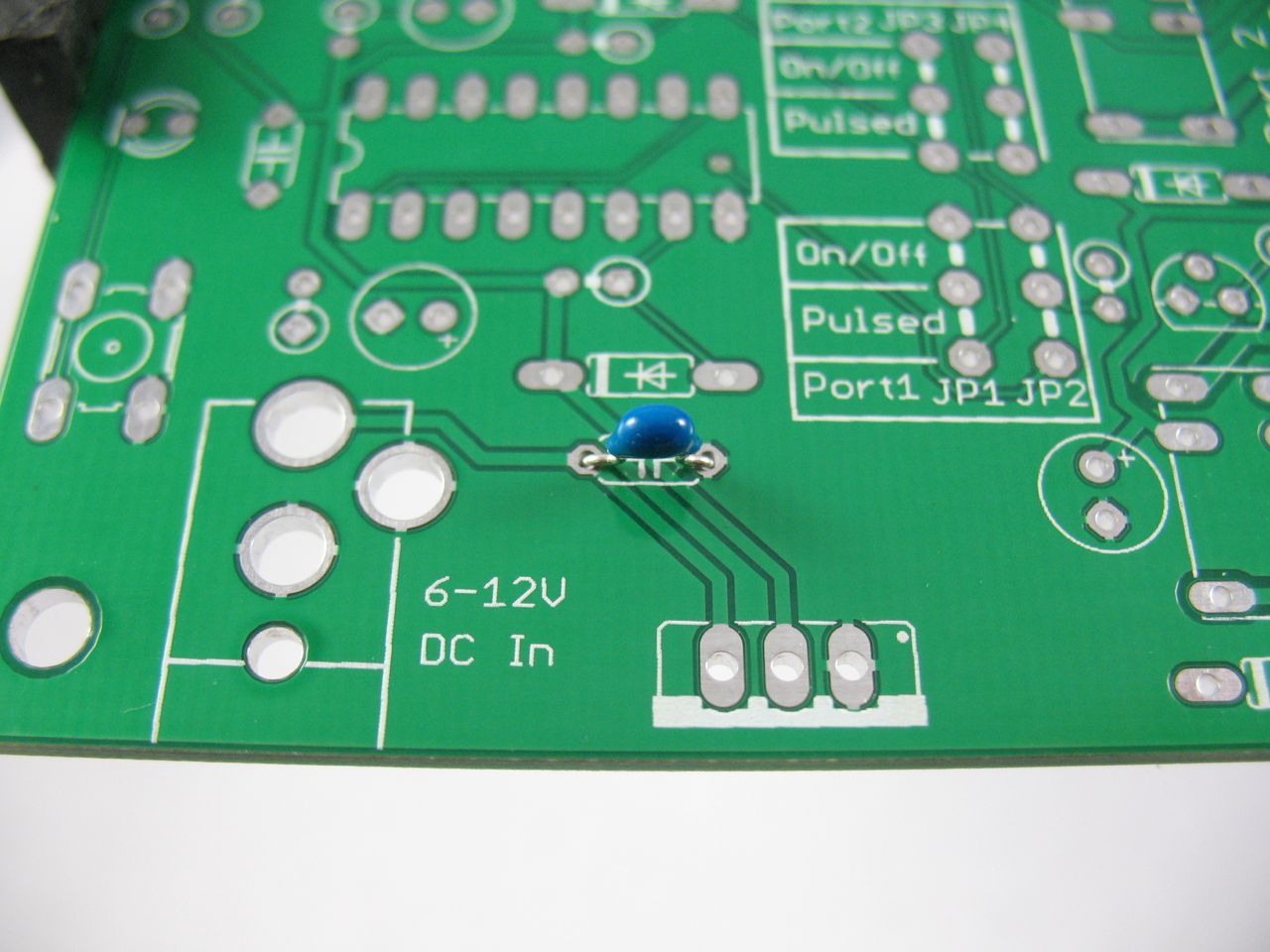

Snap the tactile switch into S1 and solder all four legs. This switch is our network-commissioning button and will let us easily associate and test our XBee’s connection to our network.

Orient one of the green LEDs in the LED3 position so that its short, negative leg is beside the “|” line on the board. For this LED the shorter leg will be by the board’s edge. Solder and snip.

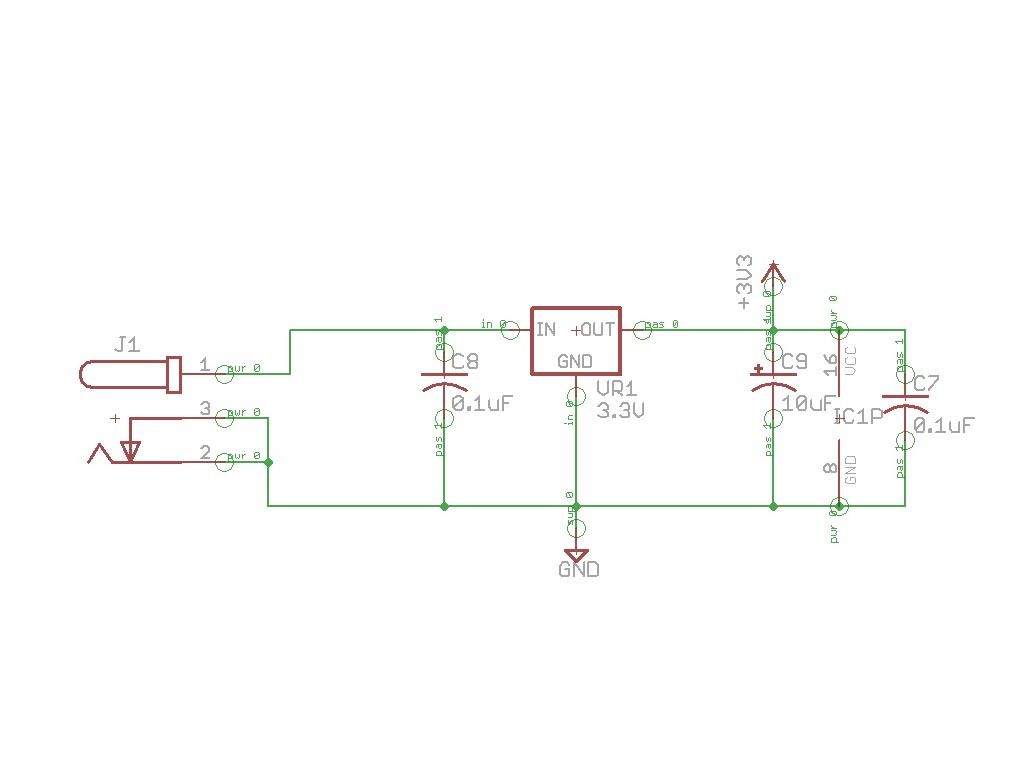

Solder a 10pF (NOT 10µF!) capacitor into C4 and a 1µF capacitor into C5. Solder a 10µF capacitor into C6, taking care to orient the longer leg so it is in the “+” hole and the shorter, silver striped negative leg in the other hole.

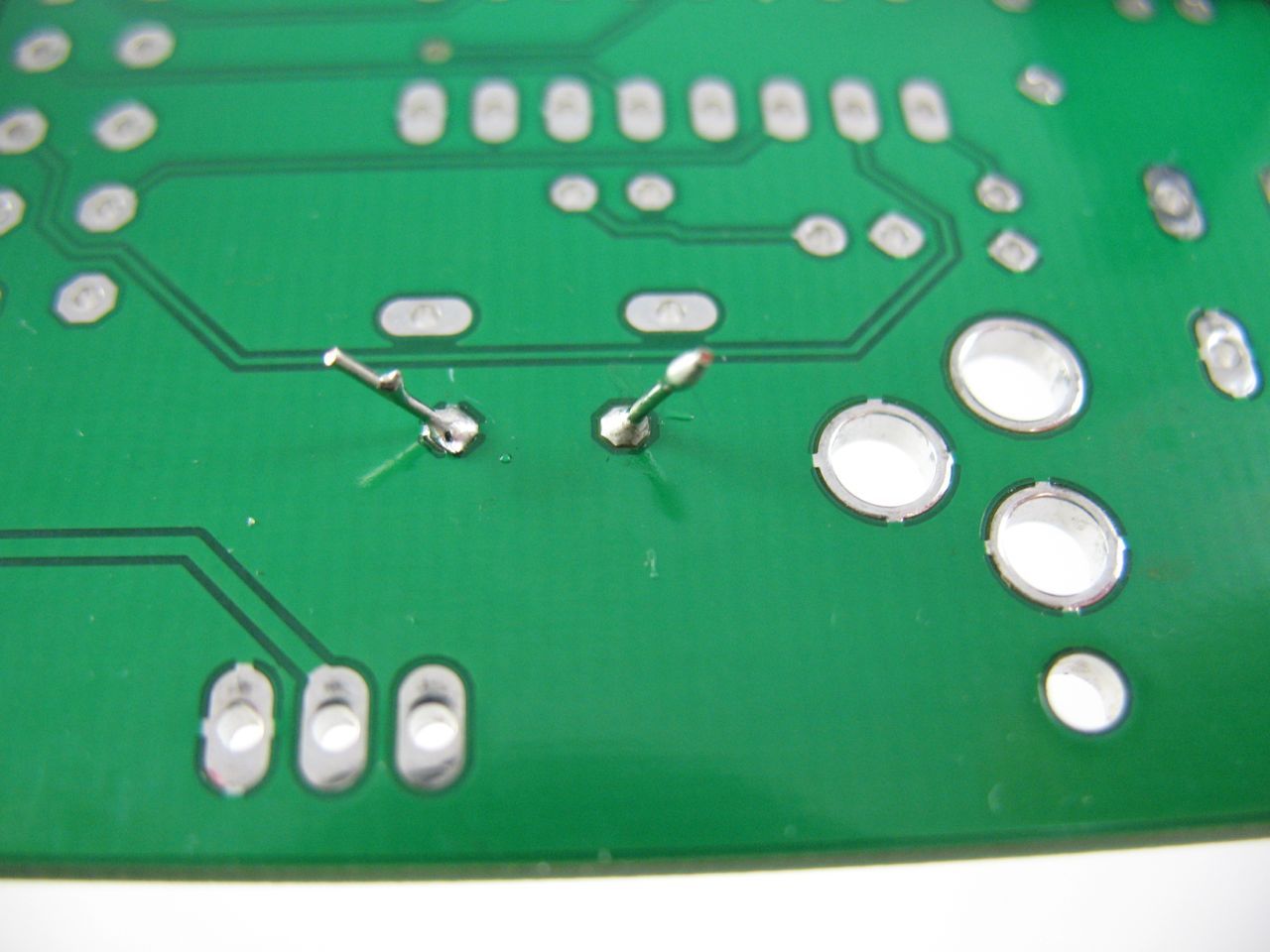

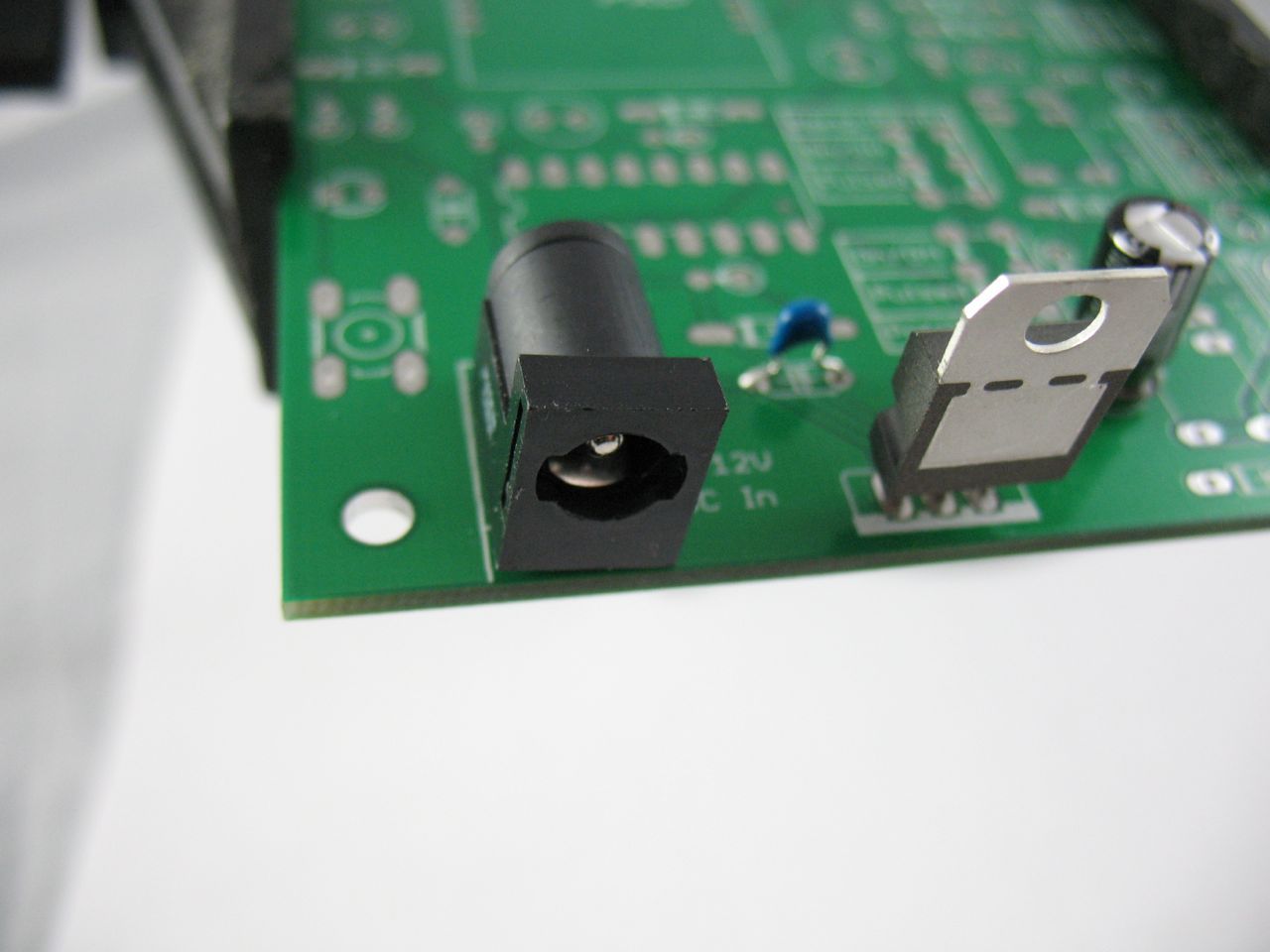

Orient four diodes so that the black stripe is to the left as shown, matching the markings on the board, then solder into D6, D7, D8 and D9. Finally, place the two terminal blocks into X3 and X4 so that the holes face the edge of the board and solder them in place.