I’m lazy. My impatience often leads me to botch important steps when I make yogurt. So to get better control over the fermentation process, I made a crockpot thermostat attachment to precisely control the temperature.

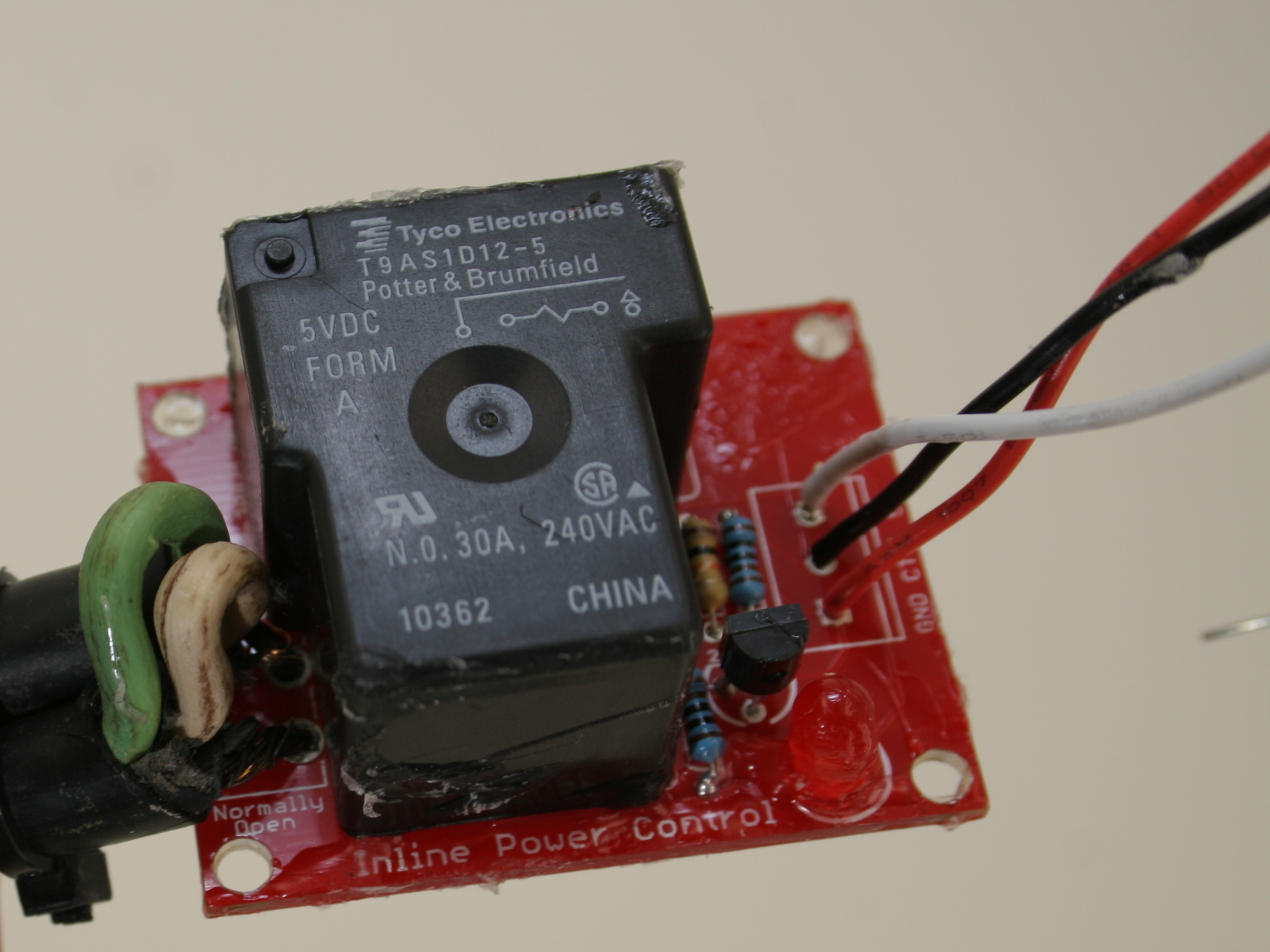

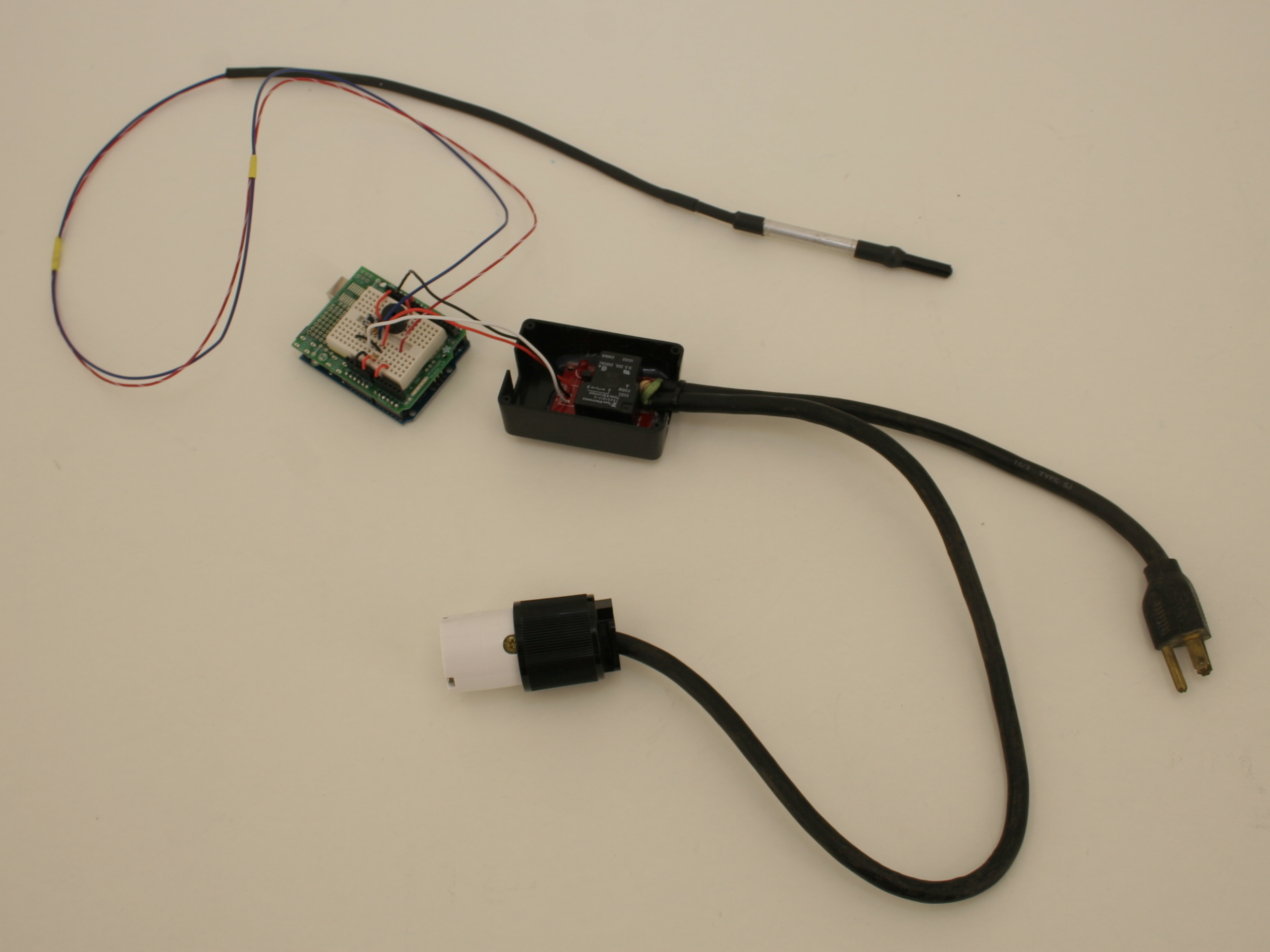

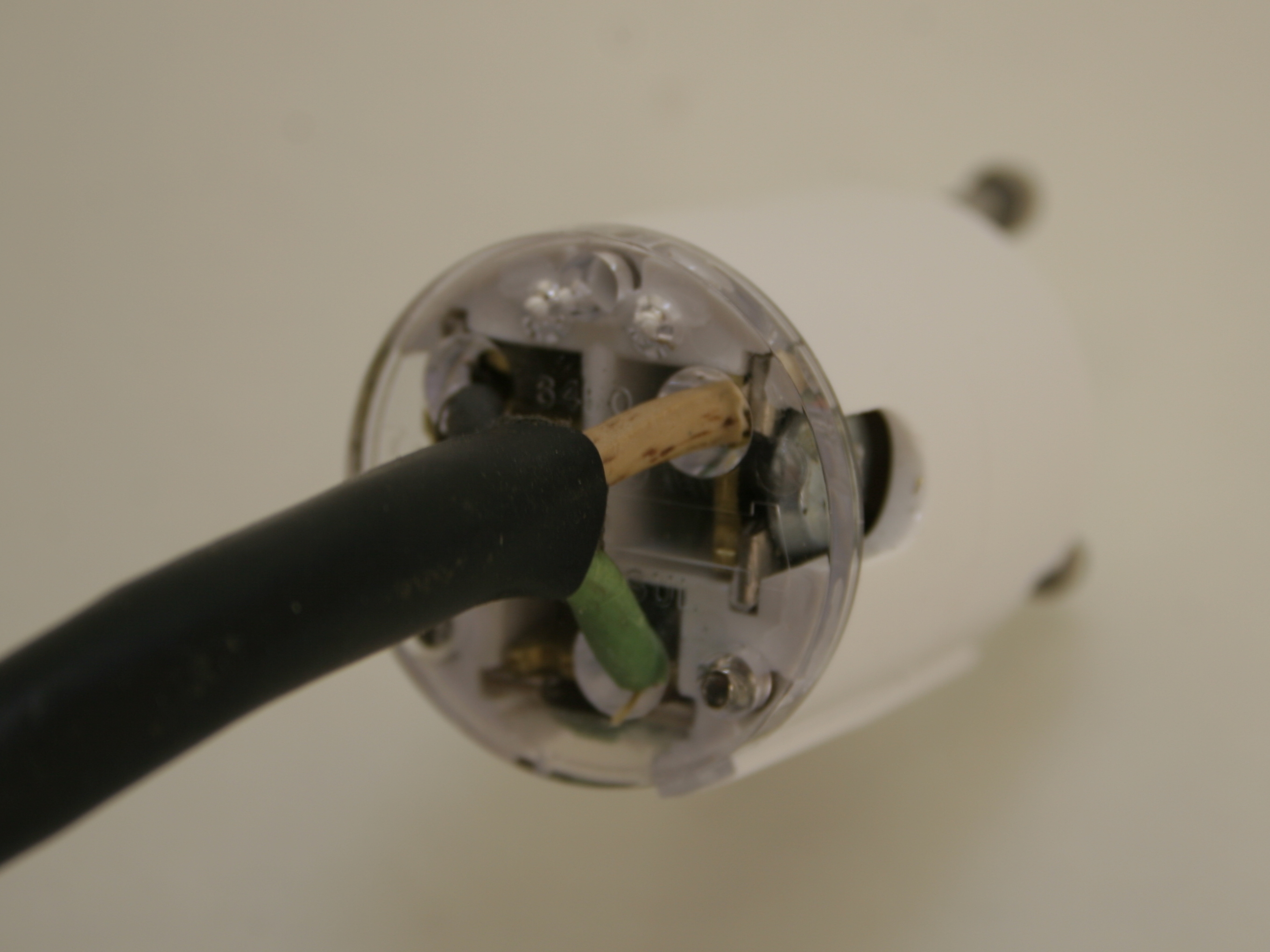

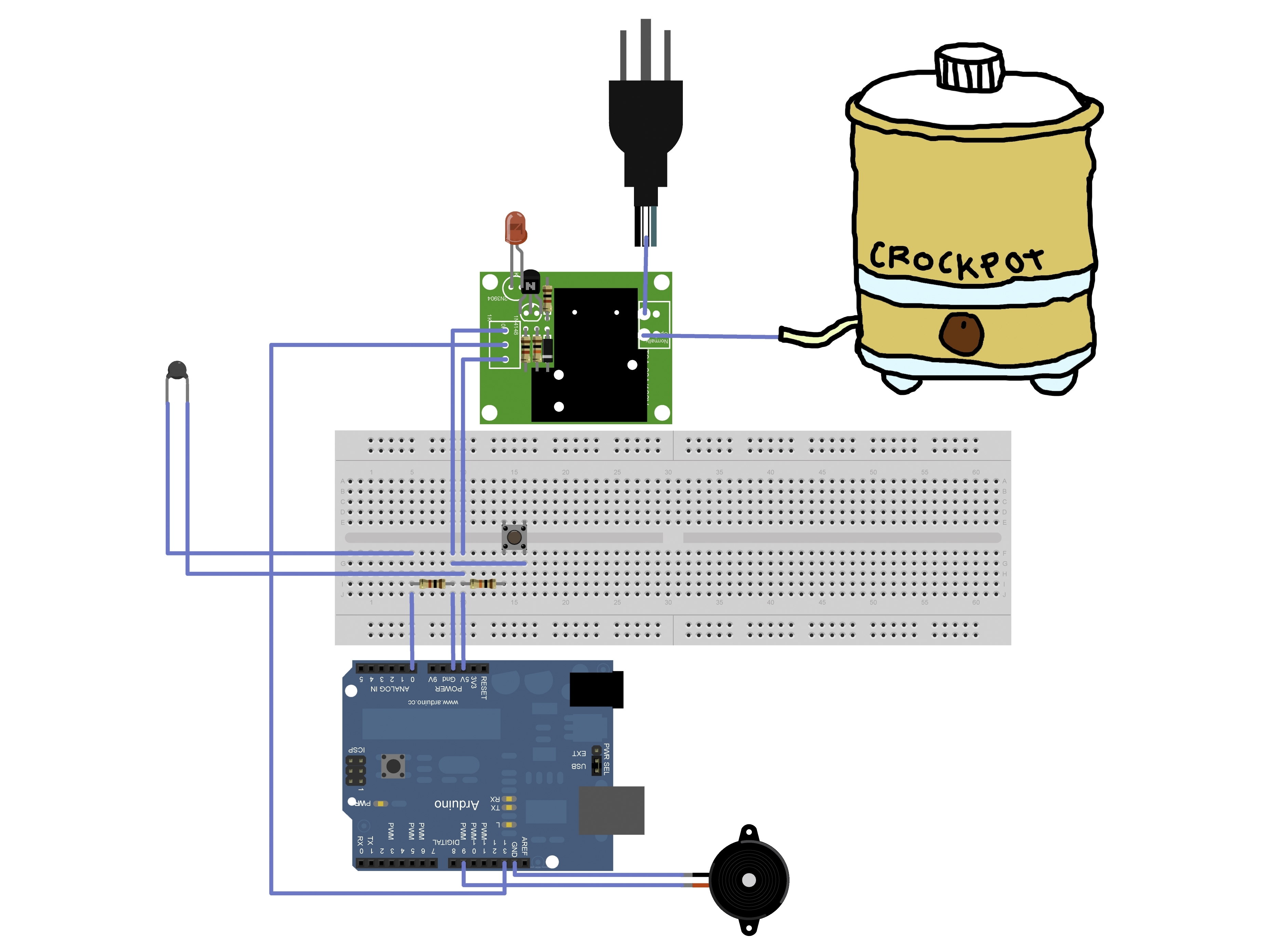

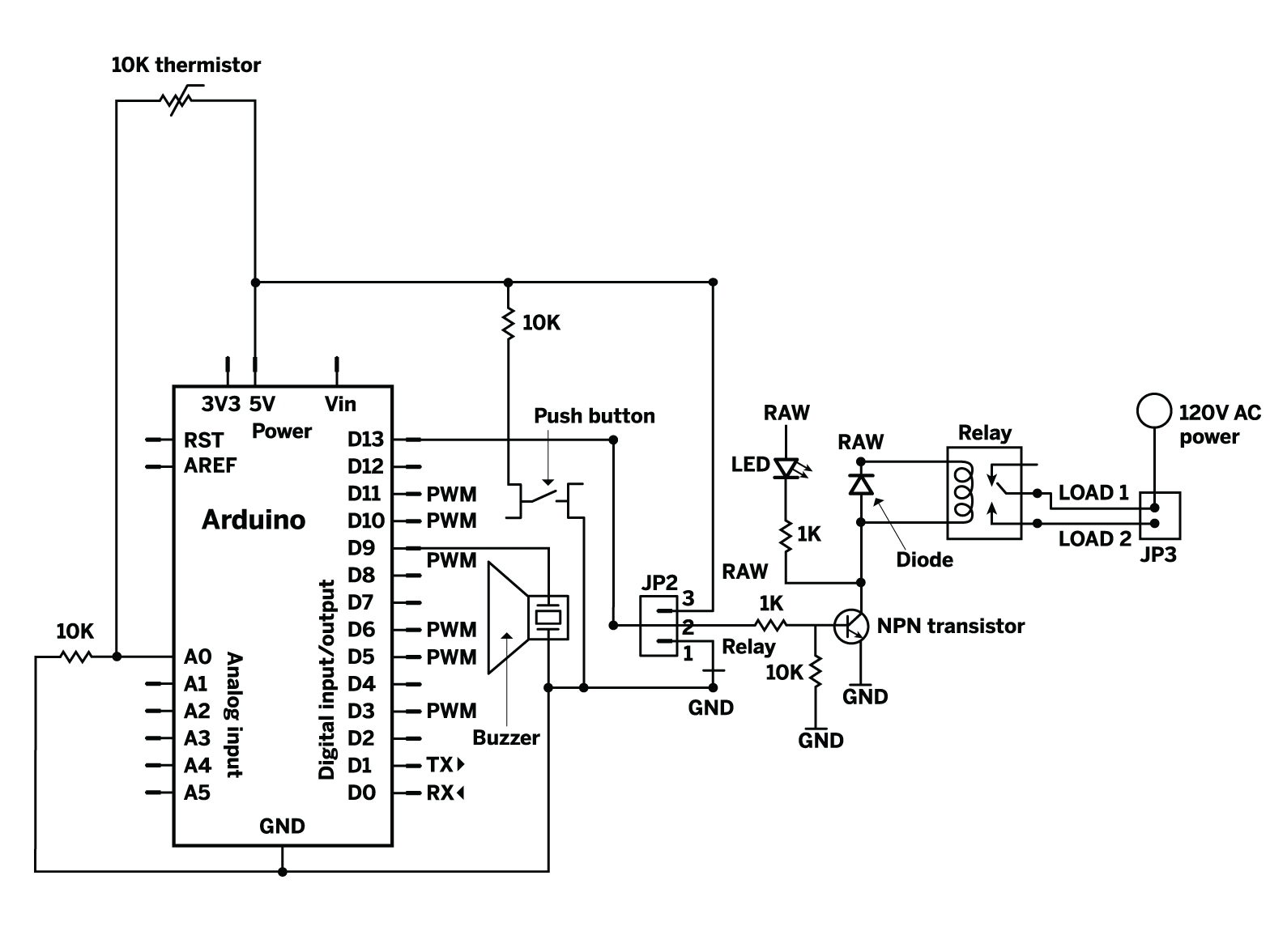

You can buy electric yogurt makers, but most of them only incubate; the heating/sterilization step still has to be done on the stovetop. I wanted to experiment with Arduino microcontroller programming and electronic circuit design in Fritzing (an open source circuit layout tool that lets users document and share designs), so why not combine them into something I enjoy doing?

With my old-school yogurt recipe (adapted from wikihow.com/Make-Yogurt), I’d use a stovetop and a candy thermometer to heat the milk to 185°F and cool it to 110°F, then use a warm oven or radiator to ferment it at 100°F. That takes a lot of attention, and more containers than I care to wash later. Even with a commercial yogurt maker, I’d probably have to heat the milk myself, and that’s the step I’m most likely to botch.

Don’t get me wrong — it’s a great recipe as long as you’re diligent. But the combination of boring, time-consuming, temperature-sensitive steps puts my diligence to the test; that’s why the automation of an Arduino-controlled crockpot yogurt maker makes perfect sense to me.