In partnership with the Missouri School for the Blind, the D’Arcy Lab in the Chemistry Department at Washington University in St. Louis creates exciting didactic tools for visually impaired students. A particular focus is put on measurement and spatial orientation – finalized designs include both a Braille measurement board and a Braille caliper (which are available to download). We seek to further the scope of our project by creating more complex objects which will help students understand the fundamentals of symmetry, a concept vital to chemistry, mathematics, fine arts, and more.

Students in undergraduate organic chemistry courses often hit a wall where a two-dimensional representation of a molecule does not translate into the intended three-dimensional object. The difficulty in conceptualizing three-dimensional space is a source of frustration for many, as it is not knowledge that can be imparted through rote memorization. It is common for college-level organic chemistry courses to recommend the use of “modeling kits” to help students make tactile connections with visualized concepts. These kits are often limited in their ability to represent systems with exceptions, falsely imparting some notion of “rigidity” of the geometry associated with chemistry, while simultaneously the students learn of favorable geometric distortions and transition states. As a group comprised mostly of chemists by education, we initially focused our efforts on designing “exceptional” molecules for 3D printing, which would help one understand geometric distortions. We furthered this concept by marking the molecules with tactile bumps and indicators, allowing one to keep track of the manipulation of a molecule in space solely through touch.

Relaying information based on tactility alone is not a new idea. Perhaps the most successful and readily recognizable realization of a tactile writing system is known as Braille, developed by the French writer Louis Braille in 1824 at the early age of fifteen. We began experimenting with ways of implementing Braille into our designs; as it turns out, the process of fused-deposition modeling printing allows for the facile creation of raised bumps on non-planar faces, perfect for Braille. Our first designs were simplistic and centered around molecular geometry (such as the 3D prints shown in the photo below), an attempt to familiarize ourselves with the design and printing of 3D models.

A print of linear carbon dioxide is embedded with our attempt at writing “CO2” in Braille – it reads rather clumsily as “capital c capital o number three three.” It is important to note that the Braille used today is not directly transliterative. While Braille can be used to express all 26 letters of the Latin alphabet, thus leading to a possible transliteration of any text in any language by a simple font change, it has been optimized throughout the years for various languages. Unified English Braille consists of a vast archive of contractions, indicators, and symbols which serve to maximize the legibility of texts written in Braille. The back of the model correctly reads “Linear,” referring to the molecular geometry of carbon dioxide, but ultimately we knew that the embedded information in future designs had to be relayed clearly and succinctly without causing excess confusion. This goal would be impossible to achieve without the help of the Braille-literate educators and students at the nearby Missouri School for the Blind providing us with valuable feedback and suggestions. The Missouri School for the Blind is recognized as the first institution in the United States to officially adopt Braille in 1860. The patience and willingness of the teachers and students at MSB to work with us and provide honest and thorough feedback on our designs led us to the work described herein.

Upon showing our models to several teachers at MSB and discussing pedagogy, the mathematics teacher mentioned the difficulty her students were having making measurements with rulers. The students are provided with rulers embedded with Braille, distributed by the American Printing House for the Blind (APH). It turns out, the major difficulty in measuring comes not from the rulers themselves, but the spatial orientation needed to measure three separate dimensions, i.e. length, width and height. Students frequently rotate objects in their hands while making measurements, quickly losing track of which side had been previously measured, leading to confusion. This is perfectly understandable – there is no fixed axis system when rotating an object in space, and therefore the distinctions of “height, width, and length” are completely arbitrary. This makes it particularly difficult for a teacher to ensure that her entire class is working with the same set of axes. We set out to create objects which would allow the student to differentiate certain sides even after rotation. These cuboids have embedded textures to allow fixed assignment of sides and directions:

Our initial design included upward pointing triangles to designate both the side commonly assigned as “length” and the top of the object. The “width” side is embedded with parallel vertical ridges. Another design includes a “cross” shaped indicator for the top of the object, and perpendicular lines on both sets of faces for both a cuboid and a cube. An attempt to relay the idea of a fixed Cartesian coordinate axis is shown as well, where an origin point (0, 0, 0) is defined by the intersection of three unique raised edge identifiers, one square, one rounded, and one separated spheres. The model can be freely rotated in space while retaining its original set of axes.

Upon introducing these objects to the students at MSB, we were excited to see them so fascinated with the actual process of 3D printing. Their sense of touch is so refined that they immediately noticed the ridges between individual layers of the PLA filament before they noticed any of the larger textural differences between the sides. We realized that the level of explanation required quickly made these objects into a source of confusion – “are everyone’s triangles pointing upwards on the left and right sides of their cuboids?” is not necessarily succinct nor clear. Furthermore, the fact that measurement was limited to specially designed objects made implementation impractical – what if the student wants to measure a book?

Brainstorming with the teachers at MSB led us to the idea of creating a “base” which would serve as a fixed three-dimensional coordinate system. In this way, any object can be measured, as it doesn’t need to be embedded with any special orientation markers. Over several months, the design was optimized, and the final product is shown below. The board was designed in AutoCAD, imported into VCarve Pro, and finally cut from medium density fiberboard with a Shopbot Desktop CNC router. Initially, we planned on using three APH braille rulers as our x, y, and z axes. This is compatible with the y and z axes, but upon rotation of the ruler for the x-axis, the numbering is found to be backwards. Thus, we set out to design our own Braille rulers which could be easily printed in any FDM printer. As these are mostly flat objects with raised lettering, they are incredibly easy to print in high resolution. The Braille embedded on their surfaces comes out clear, albeit a bit rough according to the students, so some light sanding was necessary. The z-axis is specially designed with grooves to allow a guide to slide up and down the ruler in order to facilitate the determination of an object’s height. Several iterations of this design were made, and it was determined that grooves were optimal, allowing the guide to slide with gentle force but not due to gravity.

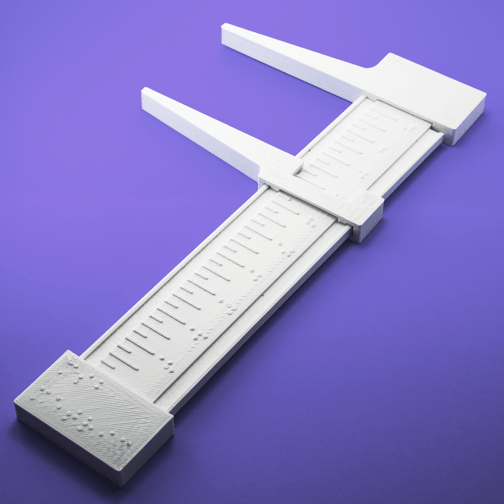

The design of the z-axis led us to consider another design that could be used independently of or in conjunction with the measurement board. One student in particular was excited at the prospect of having his own measurement board and rulers at home, so we set out to design a slightly more portable tool, beloved by makers: a caliper. The design of the ruler is similar to that of the y-axis ruler in the above photo, though the Braille has been slightly modified to count from 0–18cm. The caliper is printed in four parts: a base, a top, a slide, and the ruler itself. The slide is mounted on the guiding rails, and the top and base are fixed to the ruler with epoxy, as shown in the photo below.

The collaboration between our lab and the Missouri School for the Blind is ongoing, and we expect many more exciting designs to come. As a result of this project, the MSB has been awarded a significant grant which has enabled them to purchase their own 3D printer. This, of course, has been a hit among the students. We have been helping teachers at MSB experiment with the 3D modeling program Rhinoceros, a powerful tool which will allow them to make modifications to our designs, as well as create their own designs when needs arise. Future projects include molecular structures with internal gears allowing for bond rotations and bond angle adjustment, models with labeled molecular orbitals, more complex crystal lattices, and more.

You’re welcome to download the STL and 3DM files for the models shown here. For contact information and more about these projects, please visit our lab’s website. For further information, you can also visit The Missouri School for the Blind.

ADVERTISEMENT