Formlabs / formlabs.com

Price as tested $3,299 assembled, includes 1 liter resin

Build volume 4.9″×4.9″×6.5″

Print materials UV-cured resin

OS supported Mac, Windows

Print untethered? Computer can be disconnected after print begins

Open-source hardware? No

Open-source software? No

Printer control software PreForm

Slicing software PreForm

The Form 1 is the first entrant into the consumer SLA 3D printing market, built by Cambridge, Mass.-based Formlabs. As of press time, it’s also the highest-funded 3D printer on Kickstarter ever, raking in just under $3 million. The Form 1 uses a UV laser beam steered by a mirror galvanometer system to selectively cure a liquid photopolymer film to form each layer.

Sharp Looks, Seamless Function

This is a gorgeous machine — sleek and minimalistic with a matte aluminum chassis, OLED display, bright orange cover, and single-button interface. It has two cable connections: one power and one USB.

The Form 1 works as well as it looks. The software interface is streamlined to match the hardware; the process really is as simple as loading the file and hitting Print (or “Form,” as they call it). The PreForm software also has a unique, built-in feature that notifies you if the model has errors and helps you orient it correctly for printing. More experienced users can tweak options ranging from layer resolution to support structure parameters.

The instructions are simple and clear. Between them and the intuitive interface, we had our first object printing in less than 30 minutes out-of-the-box.

Forming Up

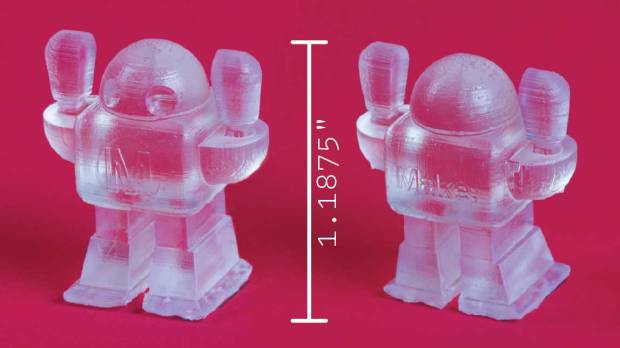

We tested the Form 1 using the bundled clear resin (an opaque grey is also available). The software offers three different resolutions: 100, 50, and 25 microns. The finer options dramatically increase print times, so we chose the lowest resolution (100 microns) in order to try as many prints as possible.

We ran prints of many sizes and durations; some filled the entire print volume and some ran well past 20 hours. The Form 1 never hiccupped. The parts were absolutely beautiful, the layers, even at the low setting, barely distinguishable.

We found the cleanup process a bit of work, as prints stuck really well to the platform and required considerable force to remove. Support structures printed under the default settings were also a bit harder to take off than seemed necessary. A small toolkit is bundled with the printer for this purpose, which is a nice touch.

All in all, Formlabs has created a modern marvel in its debut 3D printer — a thoroughly enjoyable user experience and fast, high-quality prints.

Primo features

- Needs little maintenance, setup, or calibration

- Software automatically generates support structures and clearly marks problem areas on models.

Who’s It For?

- Designers

- Architects

- Professionals

- Makers

Pro Tips

- The auto-orient feature positions the model for optimal curing and works great. Use it!

- Decrease the support structure’s “touch point diameter” for easier removal and fewer surface blemishes.

- Decrease the base size; the default is thicker than needed.

ADVERTISEMENT