Archimedes said “Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.” His timeless insight into the power of simple machines can also shed some light on the importance of appropriate tool selection — especially the most appropriate saw for the material you want to cut.

“Basic” Handsaw

Arguably the most iconic and reliable of all wood saws, it’s no doubt that this tool has changed the world. They’re also useful for reminding you that you’re out of shape when cutting a simple 2×4.

HackSaw

This type of handsaw features a fine-toothed blade tensioned in a C-frame. Commonly used for cutting metals and plastics. Take special care to clean it when cutting aluminum, as it will often gum up on softer metals.

Japanese Saws

A family of pull saws known for a thinner blade with crosscut teeth on one side and rip teeth on the other. These saws make cutting dense wood easy by first starting a guide path with the crosscut edge, then switching over to finish the cut with the rip-teeth edge. The Ryoba style is the most useful type.

Coping Saw

Popular with artists, this simple but useful cutting tool consists of a thin blade tensioned in a C-shaped frame that uses interchangeable blades for both metal and wood. It can cut tight radiuses but perhaps its most useful feature is the ability to remove the blade and thread it through a drilled hole to cut inside profiles.

Jigsaw/Reciprocating Saw

If you’ve ever needed to cut a custom shape out of a sheet of plywood or even polycarbonate, you know how useful this tool can be. If a perfectly straight line is what you need, then leave this tool on the shelf. Even in the hands of a skilled operator the blade will drift easily.

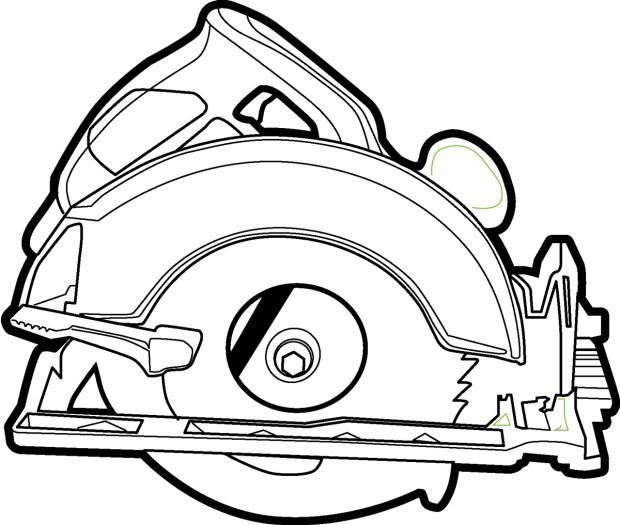

Circular Saw

There are two types of electric circular saws, the worm drive and the sidewinder. The worm drive saw has enough torque to cut through wet lumber and concrete. The behind-the-blade handle placement reduces kickback, and the blade’s left-side position makes it easy to see your cut line if you’re right-handed. The sidewinder’s motor, attached directly to the blade, weighs less but also has less torque.

Table Saw

Ripping, crosscutting, mitering, and beveling can all be accomplished using the table saw. Usually not very portable, but its versatility makes this one of the most useful tools in a shop.

Band Saw

Perhaps the most useful saw for cutting both metal and wood, this tool has loads of cutting power and runs very quiet — it won’t wake the neighbors in the middle of the night. Like jigsaws, band saws can drift if you’re not paying close attention to the line.

Miter Saw

Perhaps your dad always told you not to cut corners, but that is exactly what this saw is used for. Handheld versions are paired with a miter box fitted with guides for 45° and 90° cutting. Electric versions like the compound miter are great for cutting custom angles, making these ideal for molding and trim work.

Oscillating Saw

This seemingly novel tool began filling Christmas stockings just a few years ago. Orthopedic surgeons, however, have been using sterilized versions for decades. Its vibrating blade is useful for precise cuts within limited space.

Remember, few saws are specifically designed for cutting flesh and bone but most will do it if given the opportunity. Keep it safe!

ADVERTISEMENT