Over three days this weekend, participants in the Tikkun Olam Makers tackled real problems faced by people with special needs in an effort to create tools and devices that will help improve mobility, independence, comfort, and more. The event teamed “need knowers” — those who would use the devices — with Makers, rolling design, prototyping, and testing of inventions into one 72-hour event.

By formatting the Makeathon this way, it addresses the challenges of people who are actually in the room, says TOM founding director Arnon Zamir.

“The thing about doing something good is, most people say they’ll do it later,” says Zamir. “This is a way to make that happen now.”

His method seems to have worked. The devices created at the Makeathon offered clever solutions to real needs, and tended toward practical, replicable design. Here are five that jumped out.

1. Team Grabber

This device was designed to be used by people who must pick things up with their mouths — its goal, simply, is to grab stuff and move it around the house. It combines 3D printed parts based on a pincer and a mouth guard, with a spring mechanism to clench items, but between prototypes the team realized they had a problem: They had designed it so that when the user bites down, it opens the grabber, thinking this way it would mean less jaw work. But in testing, they realized, if you release your jaw to grab something, you lose the control you have on the bite end. So the swapped it: Now it’s clench to close.

Team Grabber was awarded the MakerBot award for Rapid Prototyping. Team members: Kim Lahtrop, Adam, Alex Gecht, Noam Platt, Maayan Kahana, Inbal Halperin.

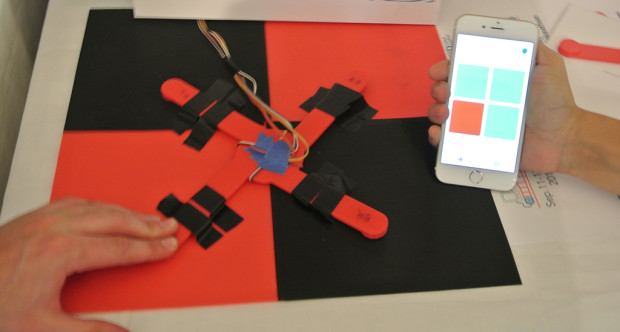

2. Team Smart Ass

Team Smart Ass designed a pressure sensing mat to fit under the seat of a wheelchair. Each prong of the 3D printed X sits atop a pressure sensor, and the whole thing runs through an Arduino. It connects to an app, which shows the pressure in darkening shades of red, indicating both where pressure points may occur, but also encouraging the user to move when one sector has seen pressure for too long. Future iterations could include more sensors for more detailed impressions.

Team Smart Ass was a co-winner of both the Google.org award for Innovation and the TechShop award for Self Manufacturing. Team members: Shaun Giudici, Paul Herzlich, Pierre Karashchuk, Yakshu Madaan, Tomás Vega, Jonathan Bank, Oscar Segovia, Hagit Alon.

3. Carry Crutches

Team Carry Crutches basically designed and 3D printed a mechanical gimbal for carrying drinks on crutches. Then they made a computer-controlled version, which uses a battery, two servos, an Arduino Uno and a MPU-6050 gyro and accelerometer sensor. A third variation included a laser-cut tray with holes for cups and utensils.

Carry Crutches received the Prize4Life award for Independence. Team members: Ilan Sherman, Benoy Bhagattjee, Matthew Wasala, Maayan Dremer, Daisy Bermudez, Tomas Garces.

4. Beity

“My home” in Arabic, Beity is a self-contained trauma management kit for refugee children. It’s portable, solar powered, and uses psychiatrist-consulted content like guided audio meditation to mitigate stress response. Simple augmented reality toys — like a fish that appears in the meditation — go with the laser-cut structure, which looks like a dollhouse. Yes, you could run it on an iPad, but it was important for the device to have no retail value. Inside, content is loaded on a Raspberry Pi via an SD card, and outside, chalkboard paint and dry erase marker make it physically interactive.

Team members: Omar Alaouf, Farah Weheba

5. Braille Sol

Braille translation programs exist, but team Braille Sol wanted to make a haptic device that allows greater control of a phone or tablet. The Arduino Uno at the heart of the device can be connected via Bluetooth or serial port, and the pins are actuated by solenoids.

Team members: Caitlin McDonnell, Corey Short, Jeffrey Edwards, Michael Han.

All photos: Nathan Hurst

ADVERTISEMENT