We’ve been testing 3D printers — shoot out style — for four years now. You’d think we’d have it down (and I’m not saying we don’t), but each year we come up with new and better ways to get the most out of the printers we test in the three days we have them. They run almost constantly.

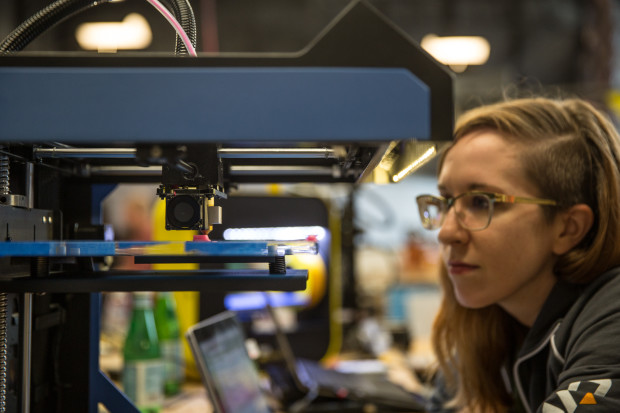

Like before, we’ve brought in some of the best 3D printers around — and by printers, we’re talking not just the devices, but the people who run them. They’re here from near (San Francisco) and far (Paris) and the Maker Media Lab is buzzing with their expertise as they select printers and fire them up.

New for this year, we’re expanding our testing beyond 3D printers: For the first time, we’ll also review CNC machines, vinyl cutters, and laser cutters. These non-printer fabrication tools are decreasing in size and cost, and as a result are proliferating throughout Makerspaces and garages and shops around the world.

“I’m actually happy they expanded to include more digital fabrications, because generally not every project can be solved with a 3D printer,” says veteran tester Luis Rodriguez, who runs the Maker Studio at Kansas City’s Science City, as well as the Mini Maker Faire there. “It’s good to show alternative machines.”

It’s one of the questions he fields often: When visitors to the Maker Studio want to build something structural, like brackets for furniture, or just something that’s too big for a desktop machine, he often steers them toward CNC. “It’s just crazy that we have so many options,” he says. “These have all appeared in the last year, so there’s really a lot to choose from.”

Around the time Rodriguez was testing printers for us last year, Claudia Ng began experimenting with 3D printing. A Bulbasaur planter, based on the Pokemon character, catapulted Ng into 3D printing notoriety, and introduced her to the inherent copyright issues, and since then she’s been working with Shapeways and on commissioned pieces.

“I’ve had my own personal methods of testing my own prints and trying to quantify them, but a lot of it was subjective,” she says. “Going through this whole rigorous process … that’s interesting to me. So in the future I can be a little more scientific about my own prints.”

A big part of that process is in the role of Kacie Hultgren. A set designer in the New York City theater scene, she uses 3D printing for scale models of sets. She’s been at our testing events for three years, and this year is judging the models from all the 3D printers, in addition to helping refine the process of logging prints and collecting data. While other testers put the printers through their paces, she’ll be working with the CNCs and cutters, so that when she sees the final prints, she’s coming at them with a fresh, impartial eye.

“That opens me up to have some hands-on time with the other digital fabrication techniques that we have in the room, and I’m really excited to check them out,” says Hultgren. “I learn so much every time I’m here, and it’s fun to get a really good picture of what’s happening in the digital fabrication space.”

The shootout features 14 printers, 8 CNC machines, 2 laser cutters, and 2 vinyl cutters.

“We know we don’t have every machine that’s on the market, but we feel like we have some very important key players,” says Make: contributing editor and test coordinator Matt Stultz. “We’re putting them through their paces, and hoping that we can see some really great results to find out how these machines perform.”

Interested in the results? We can’t share just yet, but you can see them in full in Make: Volume 48, and online in late November. And tune in on Sunday, for our wrap-up Meetup, in person or on our live stream (on our YouTube channel). There, you’ll hear from testers on trends and experiences from the shootout, and they’ll take questions from the audience.

“One of the big benefits that we see is not just the machines, but bringing in these amazing testers with great backgrounds,” says Stultz. “Sharing ideas and the sharing of knowledge helps make sure we’re developing really great tests and great content.”

ADVERTISEMENT