Name: Boyd Weiger

City: Forest Lake, Minnesota

Makerspace: Chippewa Middle School Fab Lab

Day Job: Science / Fab Lab Teacher

How did you get started making?

I got started making in my grandfather’s basement. He had tools, wood scraps, baby food jars full of hardware and “things that might be useful someday,” a 4×8′ model train setup, and space to just let me tinker. That space allowed me to explore my ideas of what I could do with tools.

What type of maker would you classify yourself as?

I’d describe myself as a maker of necessity. I’m not into making for artistic purposes. Well, except yard games. If there’s a yard game, I’ve built it — and invented a couple of my own. But that’s kind of a necessity too. I value spending fun times with family and friends outside and hanging out. If something needs to be repaired or if something needs a solution though — that’s what trips my trigger. Washer or dryer broken? I’ll take it apart, troubleshoot what’s wrong, and fix it. Or learn how to fix it, and then fix it.

I served for ten years in nuclear power in the US Navy as a nuke electrical operator. We were responsible for the generation, distribution, and control of electricity throughout the nuclear plant and out to the rest of the ship. That experience really took my technical abilities to the next level. Motor controllers, turbine generator voltage regulators, and other control circuitry have a hard time not failing in the extremely hot conditions of a power plant.

When we were in the Caribbean or the Persian Gulf, it would get really hot (ambient outside temp + heat generated by pressurized water reactor steam plant). Relays in motor controllers would stick and catch on fire, components on voltage regulators would fail, bearings would seize and burn up motors. I was always willing to volunteer to fix machinery. Digging into tech manuals to learn how machines or circuits are supposed to work, diagnosing the problem, and then effecting repairs is very interesting work to me, even to this day.

I’m also an all-year cyclist. In Minnesota, we get pretty tough conditions that take their toll on bicycles. So I built a custom bike repair stand out of black pipe and a pony clamp, and taught myself how to completely disassemble a bike, including the bottom bracket, wheel hubs, and derailleurs. I can also clean and grease the bike before reassembling it and making any adjustments.

And now you’re a science teacher? Tell us about that.

I have to say that Make: magazine is why I have this job. A friend of mine showed me Make: Vol. 5 (I think) back in the day, and I was hooked. I ordered The First Year Vol 1–4 set and subscribed right away. I have been a subscriber ever since. Make: really helped me tap into the maker movement for my own personal interests.

Long story short, a former colleague (who I now work with again), called me in December 2015 and told me that Chippewa MS was starting a maker program and he knew I’d be interested. I actually brought some of my back copies of Make: to my interview and gave them to the interview team. And here I am. Teaching students design thinking, and how to use laser cutters, 3D printers, and vinyl cutters. So thanks Make: magazine!

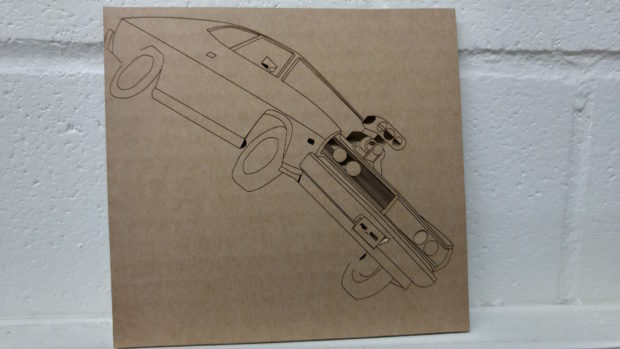

I am currently interested in making curriculum to teach 6th grade students how to use Autodesk Inventor Pro 2017 and CorelDRAW X8, so they can design for our Makergear M2 3D printers, Cameo 2 cutters, and Universal Laser Systems VLS4.60 laser cutter. I have used Google apps for education to create a self-paced learning environment where all of our 6th grade students become proficient with the use of the software and hardware I mentioned.

Students are placed in one of three tracks, each track simply determines the order they learn the software/hardware (prevents back-ups on machines). I have produced over 200 short tutorial videos with accompanying assignments for the students to learn how to use the software and hardware.

The students work through the material at their own pace. The key is that there are (with two minor exceptions) no required widgets that students have to create. The students make what they’re interested in making. Engagement in this class is through the roof. Students come to class and get right to work. They want to learn because they know that it’ll allow them to make whatever it is they’re interested in.

I spend most of every class helping students work through design issues or with specific skills one-on-one. Students aren’t texting, they’re not on Snapchat, they’re not watching cat videos on YouTube — they’re totally engaged in learning because they get to MAKE. I plan on blogging on this heavily, but I’m too busy at the moment. If you’re interested in how this course fits into our school’s overall making curriculum, I can share that. It’s actually pretty impressive.

I have learned a TON from my 6th graders this year. “Hey, Mr. Weiger looked what I found out you can do!” I hear that ALL the time, and it’s awesome. Also, I have been very up front with the students about me building this course from scratch and asking them for their input and feedback. If we want to make education better, we need to ask our students how to get better and ACT on their ideas.

Here’s a video that my school district produced about me and the class I’m teaching (there’s a minute-long intro before it gets to my class):

What’s your favorite thing you’ve made?

This class that I have created. For me as a teacher, this level of engagement and excitement is awesome. My favorite projects are currently things that my students are making, and not things I’m making. The best thing is to come in in the morning and find beds full of successfully printed models. That isn’t to say we learn from the mistakes too. I used the below video recently with my students to analyze the faults in the orange bed that had the rat’s nest:

What’s something you’d like to make next?

I’m going to make a small sound booth to improve the sound quality of the videos I’m making.

Any advice for people reading this?

If you want to learn how to do or make something, the ability for you to learn how is at your fingertips, and that is so exciting! I have learned so much this school year about 3D printer settings, Autodesk Inventor bast practices, designing in CorelDRAW, how to use a Cameo cutter or our laser cutter. It was all me reading tech manuals, watching YouTube videos, trying things, failing, and trying again. Even if you can’t search up the answer, forums are out there. I’ve found it super helpful to be able to ask experts.

Are you going to any upcoming Maker Faire events?

Minneapolis / St. Paul Mini Maker Faire — I’m planning on taking students to teach other kids how to design in Autodesk Inventor and then 3D print their design.

Who else should we profile?

Rob Reetz (@robreetz) – our school’s principal. He’s the guy who laid out the vision for this whole maker plan for our school.

Where can people find you on the web?

On my blog, and on Twitter.

We highlight different makers from our broad community to show you the faces and stories behind the projects. Meet all the amazing people featured in Maker Spotlight. Want to nominate someone, maybe even yourself? Send a note with your responses to the bolded prompts above to makerspotlight@makermedia.com.

ADVERTISEMENT