Editor’s Note: Students across the country were challenged by Samsung’s Solve for Tomorrow contest to design, create, and implement a new piece of technology that would benefit their community. Dozens of projects, addressing concerns that ranged from environmental to social, were submitted. Several of the participants agreed to write down and share their reasonings behind their projects, as well as explain how they overcame the struggles they faced. These are their stories.

The Baby Saver 2000

Written by Mason Covington and Tyler Duke, Beebe Junior High School, Arkansas

When we decided to create The Baby Saver 2000, we were trying to solve the problem of babies dying in hot cars. Last year, thirty-seven children died in hot cars. Two have already died in 2017. This is a very big problem, not only in the south where summers are very hot, but also around the world. When it is 80 degrees outside, it only takes 60 minutes for the inside of a car to increase to 123 degrees; which the child cannot stand. When the human body reaches an internal temperature of 107 degrees, organs begin to shut down.

In 2015, a young boy in Arkansas died from being left in a hot car. The incident and the trial were constantly on our local news, so this issue was fresh on our minds. We built our project in hopes that we could prevent deaths around the world. When we started, we noticed that vehicles have a lot of technology and sensors in them already, like alarms for when you leave your keys in the car, your headlights are still on, or when your seat belt is unbuckled.

However, cars have no sensors built in to them specifically aimed at saving a child’s life. In 2017, we felt like this technology should have been readily available and affordable. Where do do babies normally sit in a car? Their carseat, the perfect place for us to implement some tech to monitor a child’s condition.

We began by building a basic prototype that worked using Lego EV3. We were excited to see our concept worked, but it didn’t actually connect to the car in any way. So we played around with different ideas of how to alert parents. We originally wanted to call and text parents using an Arduino and SIM card.

However, after much debate, we felt there were too many opportunities to miss the phone call, leave your cell phone at home, or have bad cell reception. We visited an engineer from EvenFlo who gave us some great advice: don’t use any switches to activate the device. People might just stop activating it or fall victim to human error. The device should be user friendly and simple.

We then took our ideas to the Arkansas Innovation Hub in Little Rock, where an engineer, Nick Jones, helped us further develop our working prototype. We decided a pressure pad that connects the ground wire would start the Arduino and thus start the code. This was the simplest way to ensure the device was user friendly and would always come on when a child was present in the seat.

The future of this device has many different variations. We would like to have a solar panel on it that recharges the battery. We would also like a version that uses the signal from a cigarette lighter to tell the Arduino that the car is turned off and it should now start checking for temperature fluctuations. It is important to us that we continue to improve this tech, so we can give people some simple technology that can be used to help save the lives of children.

Wildlife Detector

Written by Kaika Burk, Christian Watson, Anna Burger, and KayBree Raisor, Snowflake Junior High, Arizona

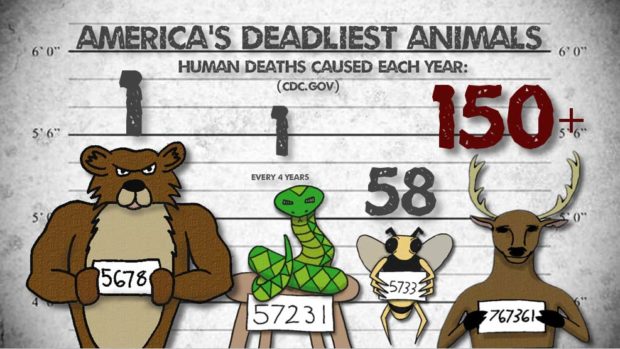

America’s deadliest animal doesn’t have big claws, sharp teeth, or venomous fangs. Surprisingly, 150 people die each year due to collisions with deer and other large wildlife.

The Federal Highway Administration of Research and Technology reported that there are more than 1 million accidents with wildlife each year. State Farm Insurance calculated last year’s average cost for these wildlife collisions is $3,995. Last year, 4 billion dollars were spent on Wildlife Collisions in the United States alone.

To help prevent future collisions, we decided to construct a low-cost wildlife detection system. Although animal detection systems aren’t new, they are extremely expensive and lack the ability to address the widespread need.

In the beginning, our design was a large and expensive pole mounted device. However, economic and manufacturing pressures forced our project to evolve. For it to be successful, we knew our device had to be low-cost, quick to fabricate, and easy to install.

Our final design is a 10-inch-tall motion detector that is placed on top of existing fence posts along the road. When triggered, it sends a radio signal to all other devices, causing 100 feet of fence line to strobe in a programed pattern. This is intended to warn drivers that an animal has approached the road.

We designed all of the 3D parts on SketchUp Make. We then sent the files to our 3D printer. After printing the objects, we sanded them down in order to remove all of the printing layers. We then painted them to get a smooth finish.

3D printing can take a long time. In order to speed up this process, we molded our original prints with silicone, and then resin cast all additional parts. We had to design all parts with slanting sides so they could be pulled out of the mold. To help save silicone, we made a plexiglass mold that was about an inch bigger on all sides in comparison to our other molds. We used a carbon dioxide laser cutter to cut the pieces.

Our electronics are controlled by an Arduino compatible Pro Mini. A separate photo (light) sensor turns off all electronics during the day by means of a MOSFET buz11 transistor. At night, the devices use two PIR (passive infrared) sensors to detect moving body heat of deer or elk.

Once triggered, the microcontroller does two things: First, it sends a radio signal to all of the other devices using a Nrf2401 transceiver module. Then, they all enter into a strobing light sequence. We encountered a little trouble setting up the communication so that all of the devices can “talk” to one another. However, we fixed this problem by setting them all up as listeners, until they are triggered to become a transmitter.

We hope our device will be used around the world in order to help prevent roadway collisions and save the lives of both people and wildlife.

A Shower Vending Machine

Written by Patrick Camacho and Jendayi London, Gulfport High School, Mississippi

While brainstorming about future project ideas, members of the National Technical Honor Society (NTHS) try to think of ways that technology can benefit their community. Homelessness became a recurring theme of our latest brainstorm, so we decided our most recent project would focus on addressing that.

We discovered the Gulfport School District has 143 homeless students. NTHS members looked into what resources were currently available for those in need. We found soup kitchens, extreme weather shelters, and a proposal for a Center of Hope that will provide temporary housing and access to showers. However, the center will not be available for some time. There is a shower program; unfortunately, the shower service is only available one day a week from 8:30 am to 11:30 am. Students without a home would have to miss school to shower.

We set our minds to finding ways of providing personal hygiene items to impoverished students facing hardships in our community. After much discussion, brainstorming, and inspiration from Taylor Rosenthal’s first-aid vending machine, we figured it out: a vending machine that dispenses personal hygiene items and provides access to a secure shower stall!

The plan is to upcycle available technology. To reduce costs and ensure the machine maintained power (so any student could use it whenever they needed it), we decided to use solar power. Solar panels will provide enough power to run the machine and trickle charge into two deep cycle marine batteries throughout the day. The machine will run on those batteries through the night.

NTHS’s Build Team is currently working with local technicians and electrical engineers who specialize in solar energy to create a complete diagram of the solar system needed to power our vending machine. Additionally, the machine will accept tokens which school counselors and local non-profits will distribute to individuals in need. With the help of Gulfport High School’s Construction Technology Instructor, NTHS members will create design plans for the shower stall component.

The Communications Team reached out to local non-profit organizations and businesses to raise awareness and gather donations for the project. The reception from the community was heartwarming. Allen Beverages donated an old vending machine, The Nourishing Place (a local non-profit) agreed to be the site of the first machine, the Congregational Partnership (a collection of Gulfport non-profit organizations) pledged their support to our project, and local businesses donated supplies for the machine.

Drones in Agriculture

Written by Elexus Johnson and Eric Crane, Gering High School, Nebraska

In twenty years, kids will not be staring at the big crop duster “blanket” spraying fields, but instead looking at precision guided drones spraying minimal amounts of herbicide. This new process will control weeds and infestations while helping farmers make a more economic and environmentally responsible choice.

In October of 2016, we agreed that a major problem in our community is the nitrate levels in our water supply. The Ogallala Aquifer supplies water to 2.3 million people, and is considered by many to be Nebraska’s goldmine. Recently the nitrate levels in the aquifer have been observed at record levels. We set out to find a change.

We discovered that blanket spraying crops is one of the biggest problems for nitrate levels in the aquifer. For example, a farmer could have your typical 5 acres of crop. An application of herbicide for that size could be as large as 3 pounds (or 19 gallons) per acre. Altogether, this means farmers could be using 95 gallons of herbicide on their crops. That is just the first blanket too, there is no telling how many times they will continue to apply the herbicide. That is a massive amount, and most of it is wasted. It is not as if the entire farm is covered in weeds.

What could take away all that herbicide but still get the job done efficiently? Would there be a way to eliminate the cost as well? With our new drone spraying system, we hope to have come up with a permanent solution.

Our plan was to create two available drones, a scout drone and an applicator drone. By using the NDVI camera on the scout drone, GPS way points survey and capture pictures of the field. Once the scout has finished, we can download the images to a computer. The images are then transferred over to the data mapper application to take the pictures and form them into one single image. This image can be put under a series of filters, changing the colors to differentiate crops from weeds.

With the help of a geographic information systems specialist (GIS) from the North Platte Natural Resources District, we have created a user friendly program that anyone could use without the need to be educated on its design. Implementing the use of UAV imagery and multiple filters will isolate weeds and limit the time needed to analyze the (NDVI) images. Once the weeds have been located, the applicator drone can follow the scout’s flight path. The drone will be able to hover just a few inches above the weed to spray it.

The class designed our final spraying platform with the help of a 3D printer. In a controlled environment, we also created an artificial grid pattern to imitate a field with weeds marked by red X’s. Our tech proved to be a success. Our applicator drone was able fly down each row and spray the designated weeds without fault.

ADVERTISEMENT