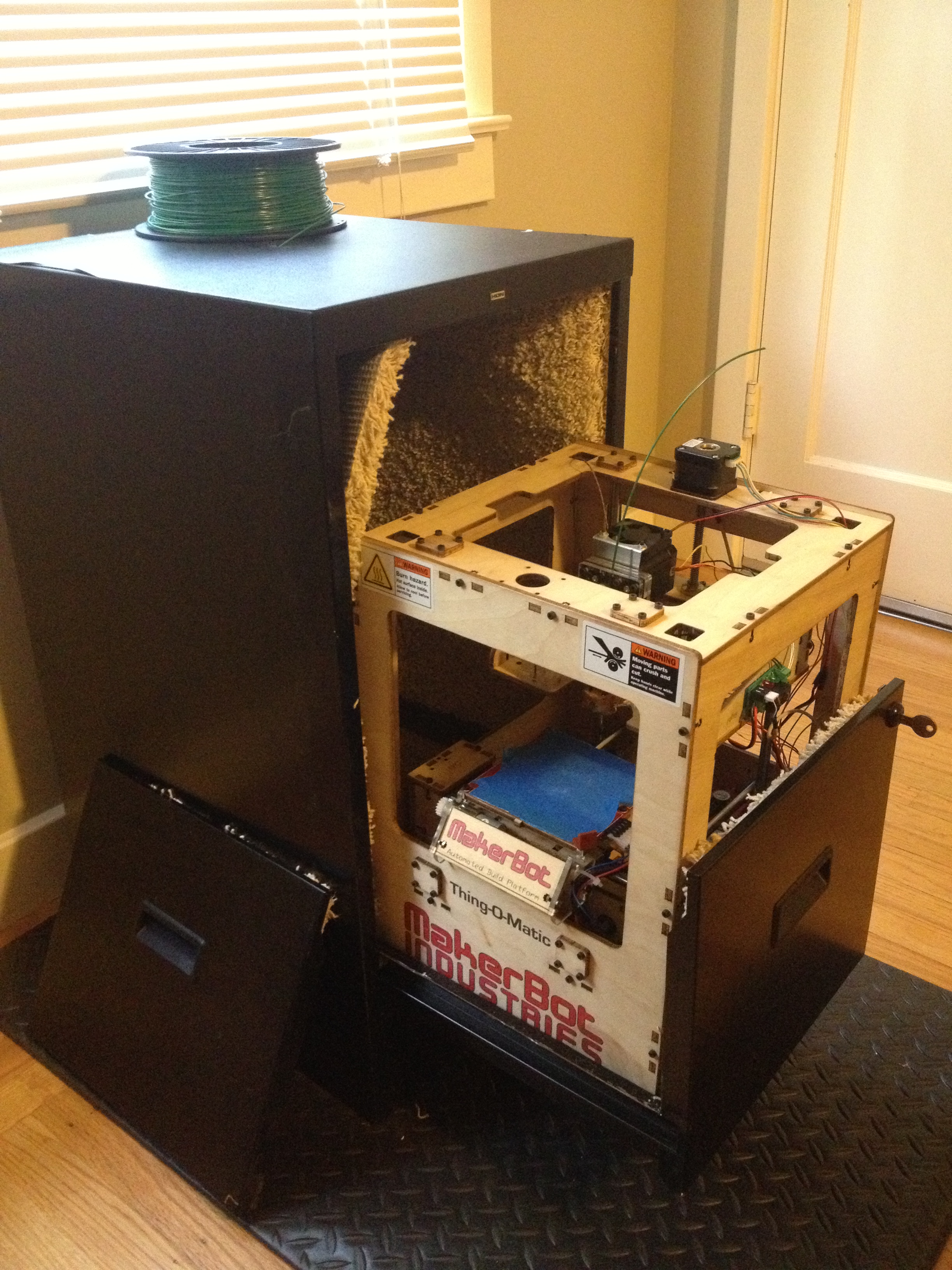

MAKE fan Michael Schaller send along this project he built at home to deal with one very important factor of the 3D printing experience: noise. From Michael-

Just for background: I live in an old house that doesn’t have good insulation. We have some neighbors that live below us and sound travels really easily through the floors and walls. I wanted to do long prints, especially at night, but you could hear the printer all through the house. I built this using some off-the-shelf materials to dampen the sound. An added advantage that I didn’t consider at first is that it keeps the inside of the cabinet at a warm temperature (~110º F) during the build. I thought it might be a problem, but I think it actually produced more consistent parts because it reduced the shrinkage of the plastic during the build.

My wife called it the ‘fire box’ because she was worried about it catching on fire, but after monitoring the temperature for a few builds I stopped worrying about it.