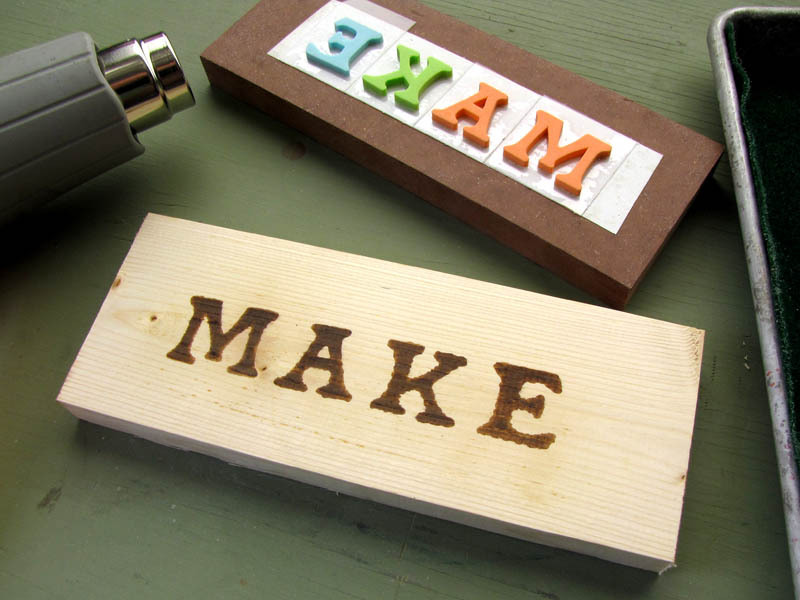

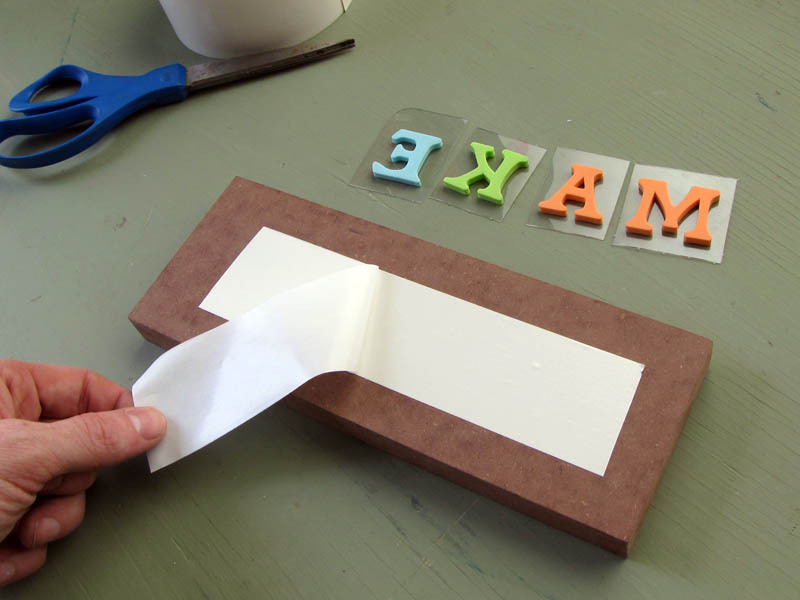

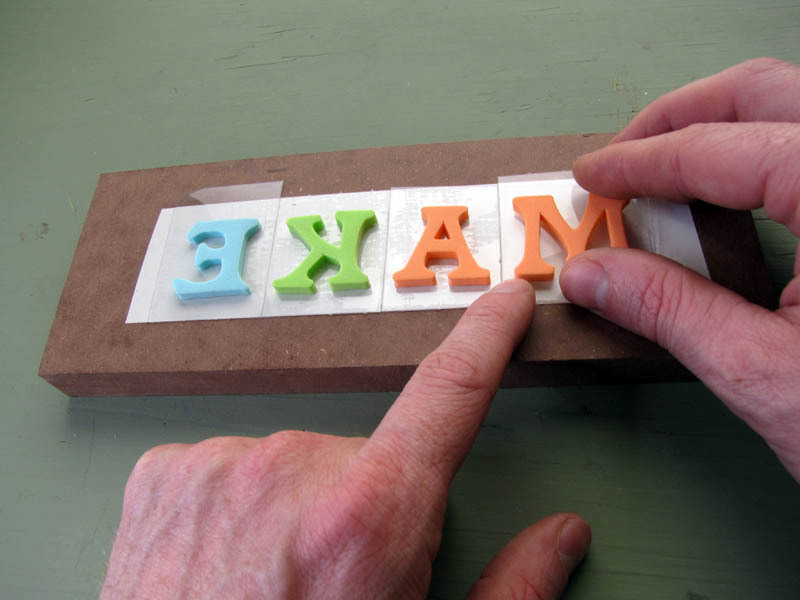

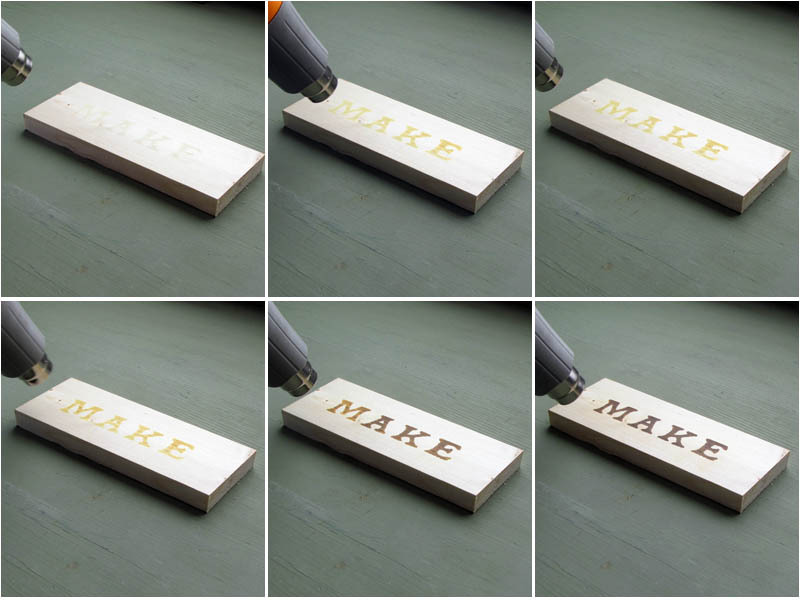

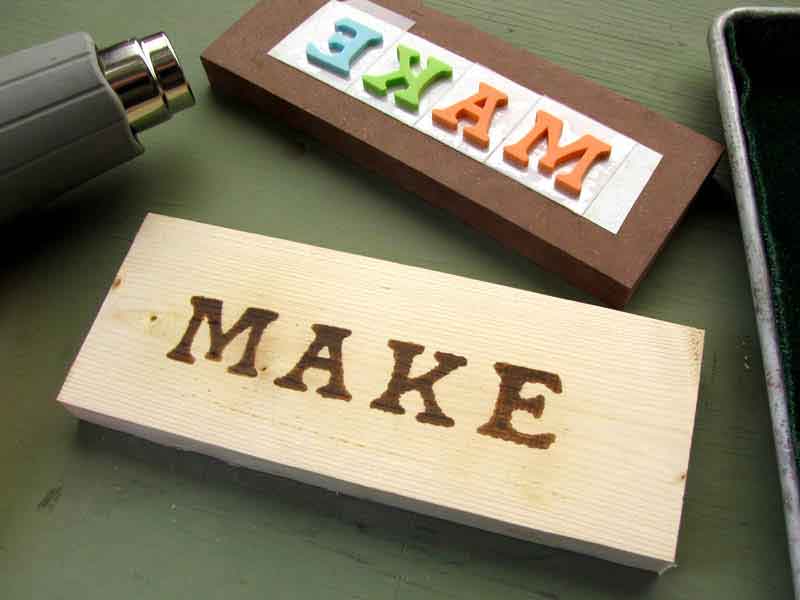

If you want to apply a maker’s mark or other repeated pyrograph to wooden goods, but can’t justify the expense of a custom branding iron, an indistinguishable effect can be achieved by applying a strong solution of ammonium chloride, for instance using a foam rubber stamp, followed by relatively mild heat.

On heating, ammonium chloride decomposes into ammonia gas and strong hydrochloric acid (NH4Cl → NH3 + HCl). Ammonia diffuses away into the atmosphere, leaving the strong acid behind, which burns the wood. The resulting chemical burn is identical to a heat burn in most respects.

This process sounds nastier than it is, in practice, and although prudence dictates erring on the side of caution and working with plenty of ventilation, the process does not produce a noticeable smell either of ammonia or of HCl. The only detectable odor is burning wood.

CAUTION: Ammonium chloride fumes can cause respiratory harm or an asthma-like allergy, so avoid breathing dust, vapor, mist, or gas. Wash thoroughly after handling. Store ammonium chloride capped at room temperature and protect it from heat.