In our consumer society, most materials are discarded once they become old or obsolete. Many of these rejects have a hidden beauty that can be brought back to life in a new form; discarded or never-used printed circuit boards (PCBs) fall into this category.

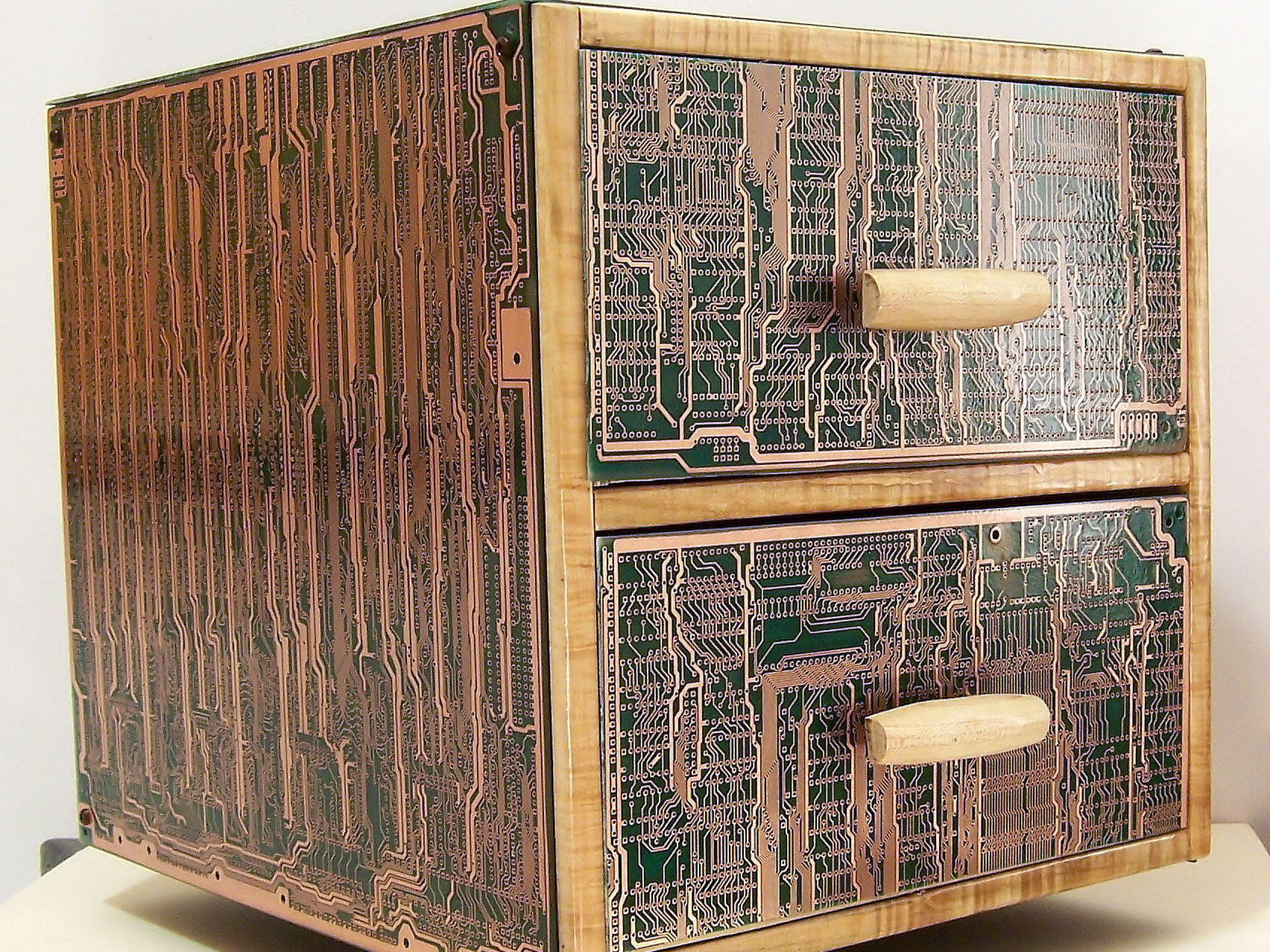

A consequence of the high-tech bubble bust of a few years ago is that millions of PCBs were never used and are now resting in warehouses, waiting for a new lease on life. This project shows how to make a 2-drawer case and “veneer” it with recycled PCBs. The PCBs’ coppery traces look like metallic petroglyphs, and the case looks great in any modern living room or office. Depending on the size, the case can hold precious papers, jewelry, stationery, pens and pencils, or CDs.