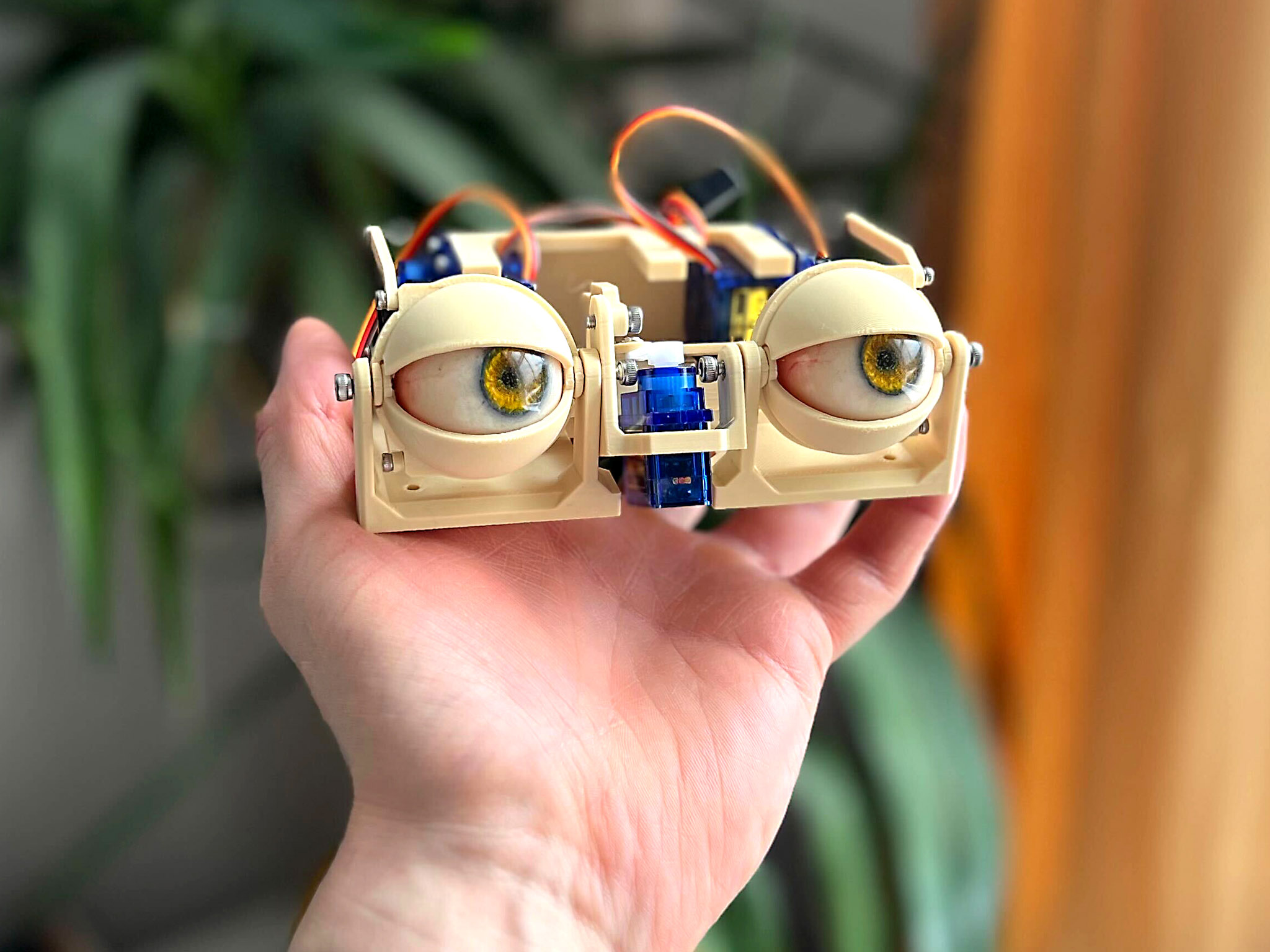

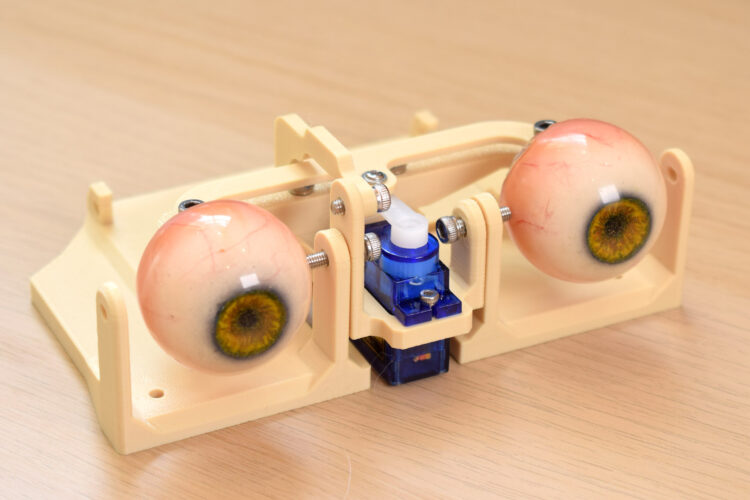

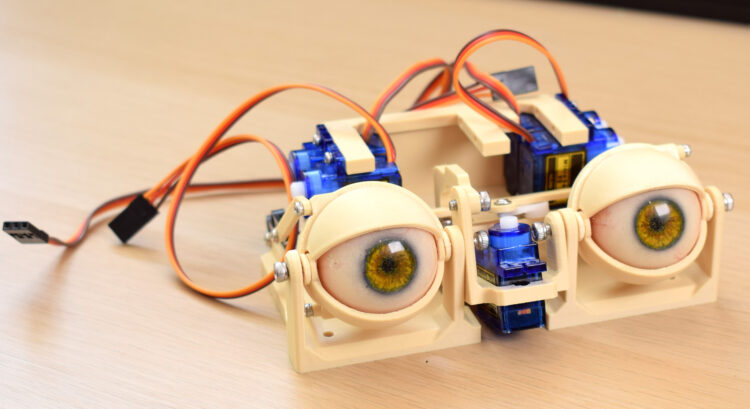

Animatronics, once relegated to the realms of theme parks and big-budget movie sets, are experiencing a renaissance in our DIY culture. Perhaps it’s childhood nostalgia, certain horror-themed video game franchises, or the desire to explore the intersection of technology and artistry. Whatever the reason, there’s excitement surrounding the creation of animatronic marvels. And amidst this wave of enthusiasm, there’s never been a better time to embark on your own animatronic journey! In this project you’ll build a realistic eye mechanism you can control with a joystick — and integrate into any project you like!

To start with, my code will allow you to look left and right, up and down. As the gaze moves up or down, I’ve programmed the eyelids to follow them subtly which adds a surprising amount of realism. Using a button, you can also trigger a rapid blink. Since we’re using a programmable Arduino you could also write your own code to move the eyes autonomously or even integrate them into a larger animatronics project!